In the dynamic world of business, understanding and managing the lifecycle of products is crucial for sustained success. Product Lifecycle Management (PLM) stands as a cornerstone in this process, encompassing the management of a product’s journey from conception to disposal. This guide aims to shed light on the essence of PLM, its critical phases, and the strategic value it adds to businesses. By breaking down complex concepts into digestible explanations, we embark on a journey to explore the intricacies of PLM and how it can be leveraged to foster innovation, efficiency, and competitive advantage.

Table of Contents:

– What is product lifecycle management?

– The stages of product lifecycle management

– The benefits of implementing PLM

– Challenges in product lifecycle management

– Future trends in PLM

What is product lifecycle management?

Product Lifecycle Management (PLM) is a strategic approach to managing the entire lifecycle of a product from its inception, through design and manufacture, to service and disposal. It integrates people, data, processes, and business systems, providing a product information backbone for companies and their extended enterprise. PLM is not just a technology but a business strategy that helps organizations to innovate, develop, and launch products more efficiently and cost-effectively.

The concept of PLM emerged from the need to coordinate the complex activities involved in developing and maintaining a product. It encompasses a wide range of disciplines, including product design, engineering, manufacturing, and supply chain management. By facilitating better decision-making and collaboration across these disciplines, PLM enables companies to bring high-quality products to market faster and at a lower cost.

PLM systems serve as a central repository for all information related to a product, ensuring that every stakeholder has access to the most current data. This centralized approach eliminates silos, reduces errors, and enhances productivity by streamlining processes and enabling more effective collaboration among teams.

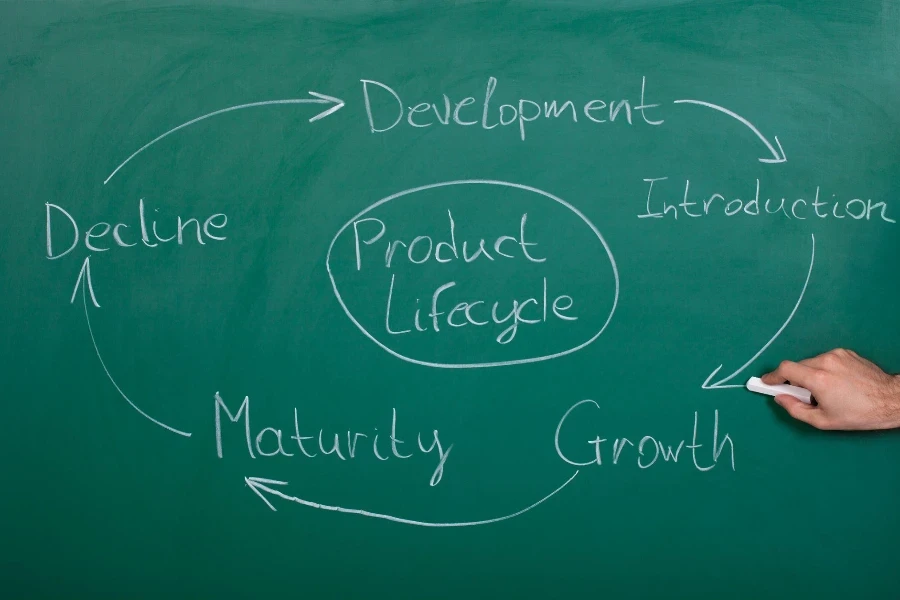

The stages of product lifecycle management

Understanding the stages of the product lifecycle is fundamental to grasping the full scope of PLM. These stages include the conceptual phase, design and development, manufacturing, service and maintenance, and finally, disposal or recycling. Each phase has its unique challenges and requirements, and PLM provides a framework to manage these effectively.

During the conceptual phase, PLM tools help in capturing ideas, conducting feasibility studies, and defining product requirements. This early stage is critical for aligning product concepts with market needs and organizational goals. In the design and development phase, PLM facilitates collaboration among designers, engineers, and other stakeholders to create detailed product models and simulations.

As the product moves into manufacturing, PLM ensures that design data seamlessly transitions into production processes, maintaining the integrity and intent of the original product design. During the service and maintenance phase, PLM enables companies to support their products in the field, managing updates, and addressing issues. Finally, in the disposal or recycling stage, PLM assists in ensuring products are retired responsibly, emphasizing sustainability.

The benefits of implementing PLM

Implementing PLM can bring about transformative benefits to an organization, enhancing product quality, reducing time-to-market, and driving innovation. By providing a unified, transparent view of product information, PLM enables more informed decision-making throughout the product lifecycle. This leads to improved collaboration among cross-functional teams, reducing errors and rework.

Another significant benefit of PLM is its ability to streamline operations and reduce costs. By automating workflows and standardizing processes, companies can achieve greater operational efficiency. Furthermore, PLM supports regulatory compliance by maintaining detailed records of product development activities, materials, and changes.

Innovation is another area where PLM plays a pivotal role. By facilitating the rapid iteration and testing of ideas, PLM helps companies to stay ahead of market trends and meet evolving customer demands. This agility is critical in today’s fast-paced business environment, where the ability to quickly adapt and innovate can set companies apart from their competitors.

Challenges in product lifecycle management

While PLM offers numerous advantages, implementing and managing a PLM strategy comes with its set of challenges. One of the primary obstacles is the complexity of integrating PLM systems with existing business processes and IT infrastructure. This requires careful planning and execution to ensure a smooth transition and minimize disruption to operations.

Another challenge is managing the cultural change that accompanies PLM implementation. Shifting to a more collaborative and integrated approach to product development requires buy-in from all stakeholders. Overcoming resistance to change and fostering a culture of continuous improvement is essential for realizing the full benefits of PLM.

Data management and security are also critical concerns in PLM. With the vast amount of sensitive product and customer data involved, ensuring data integrity and protecting intellectual property are paramount. Companies must implement robust security measures and data management practices to mitigate these risks.

Future trends in PLM

Looking ahead, several key trends are poised to shape the future of PLM. The integration of advanced technologies such as artificial intelligence (AI), the Internet of Things (IoT), and augmented reality (AR) into PLM systems is enhancing capabilities and opening new possibilities for product development and lifecycle management.

AI and machine learning are enabling more sophisticated data analysis and decision-making, while IoT connectivity offers real-time insights into product performance and usage. AR is transforming product design and maintenance, allowing for more immersive and interactive experiences. These technologies are making PLM more powerful and versatile, enabling companies to achieve greater innovation and efficiency.

Sustainability is another critical trend influencing PLM. As environmental concerns become increasingly paramount, companies are leveraging PLM to design more sustainable products and processes. PLM supports the integration of sustainable materials, energy-efficient manufacturing, and end-of-life recycling into the product lifecycle, contributing to a more sustainable future.

Conclusion:

Product Lifecycle Management is a strategic approach that brings coherence and efficiency to the complex process of managing a product’s lifecycle. By embracing PLM, companies can improve collaboration, accelerate innovation, and achieve a competitive edge in the marketplace. Despite the challenges, the future of PLM is bright, with emerging technologies and a growing emphasis on sustainability promising to further enhance its value. As we look forward, it’s clear that PLM will continue to play a pivotal role in shaping the products and businesses of tomorrow.