Choosing the right drill bit holder can make a significant difference in the efficiency and organization of your workshop. With numerous options available, it can be challenging to determine which holder best suits your needs. This article delves into the essential aspects of drill bit holders, offering valuable insights to help you make an informed decision.

Table of Contents:

– Understanding the importance of a drill bit holder

– Key features to look for in a drill bit holder

– Materials and durability considerations

– Types of drill bit holders

– Maintenance tips for longevity

Understanding the importance of a drill bit holder

A drill bit holder is more than just a storage solution; it is a tool that enhances the efficiency and safety of your workshop. Proper organization of drill bits can save time, reduce the risk of injury, and prolong the lifespan of your tools.

Organized drill bits mean less time spent searching for the right size, allowing you to focus on your project. This increased efficiency can be crucial in professional settings where time is money. Furthermore, an organized workspace reduces clutter, which can significantly minimize the risk of accidents.

The right drill bit holder also protects your drill bits from damage. When drill bits are kept in a holder, they are less likely to get knocked around, which helps maintain their sharpness and overall condition. This protection extends the life of your bits, ensuring they are always ready for use.

Key features to look for in a drill bit holder

When selecting a drill bit holder, several key features should be considered to ensure it meets your needs. The first feature to look at is capacity. Depending on your requirements, you might need a holder that can accommodate a wide range of bit sizes and types.

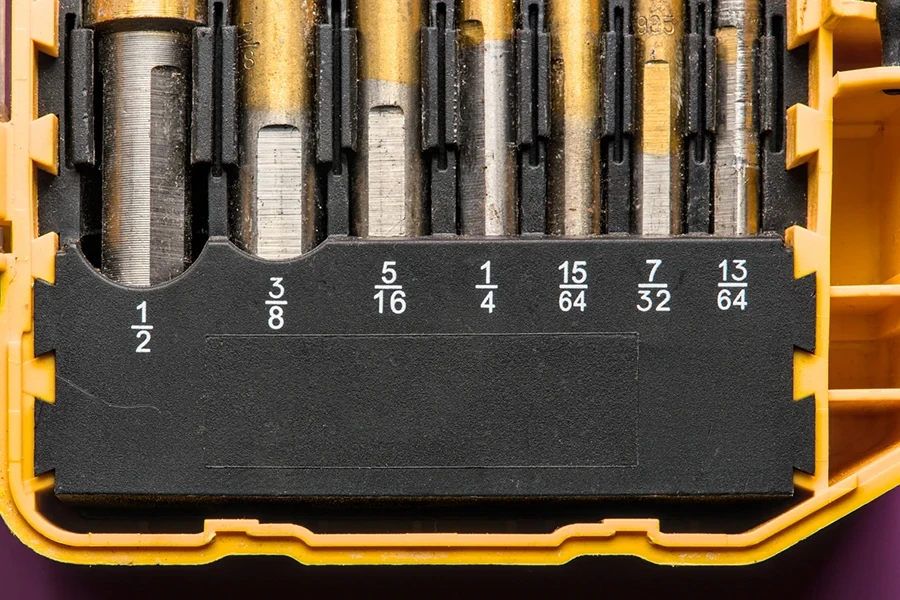

Another essential feature is ease of access. A good drill bit holder should allow you to quickly and easily retrieve the bit you need. This can be achieved through clear labeling or a well-organized layout that reduces the time spent searching for the right bit.

Durability is also crucial. A drill bit holder should be made from materials that can withstand the rigors of a workshop environment. Look for holders made from high-quality plastic, metal, or wood that offer robust protection and longevity.

Materials and durability considerations

The material of a drill bit holder greatly affects its durability and functionality. Plastic holders are lightweight and resistant to corrosion, making them a popular choice. However, they may not be as durable as metal or wood options.

Metal holders, often made from steel or aluminum, provide excellent durability and protection for your drill bits. These holders are resistant to impacts and can withstand harsh workshop conditions. However, they may be heavier and more expensive than plastic options.

Wooden holders offer a balance between durability and aesthetics. They provide good protection for drill bits and can be a stylish addition to your workshop. However, they may require more maintenance to prevent damage from moisture and other environmental factors.

Types of drill bit holders

There are various types of drill bit holders available, each designed to meet different needs. Fixed drill bit holders are stationary units that can be mounted on a wall or placed on a workbench. These holders are ideal for workshops where organization and accessibility are paramount.

Portable drill bit holders, on the other hand, are designed for mobility. These holders are perfect for professionals who need to transport their tools between job sites. They typically come with handles and secure closures to keep bits safe during transit.

Magnetic drill bit holders offer a unique solution for quick access and storage. These holders use strong magnets to keep drill bits in place, allowing for easy retrieval and organization. They can be mounted on metal surfaces, providing flexibility in how they are used in the workshop.

Maintenance tips for longevity

Proper maintenance of your drill bit holder is essential to ensure its longevity and effectiveness. Regularly clean your holder to remove dust and debris that can accumulate over time. This not only keeps your workspace clean but also prevents potential damage to your drill bits.

Inspect your drill bit holder for any signs of wear and tear. Check for cracks, dents, or other damage that could compromise the holder’s integrity. Address any issues promptly to avoid further deterioration.

Additionally, consider the environment in which your drill bit holder is stored. Keep it in a dry, cool place to prevent damage from moisture and extreme temperatures. If your holder is made of wood, occasional treatments with appropriate wood preservatives can help maintain its condition.

Conclusion

Choosing the right drill bit holder involves considering various factors such as capacity, ease of access, and material durability. By understanding the different types of holders and how to maintain them, you can ensure your drill bits are well-organized and protected, enhancing the efficiency of your workshop.