Line boring, a crucial process in the machinery world, involves enlarging a hole that has already been cast, ensuring the holes are perfectly aligned and sized according to specifications. This technique is essential in various industries, including automotive, aerospace, and heavy machinery, for its role in repairing or modifying large equipment components. This article aims to shed light on the key aspects of line boring, breaking down its complexity into understandable segments, and providing insights into how it can benefit your operations.

Table of Contents:

– What is line boring and why is it important?

– The technicalities of line boring machines

– Common applications of line boring

– Challenges in line boring and how to overcome them

– Selecting the right line boring service

What is line boring and why is it important?

Line boring is more than just a machining process; it’s a precision engineering art that breathes new life into heavy machinery. At its core, line boring corrects the bores that have been worn out due to stress and strain over time. This process ensures that the holes are perfectly aligned to the original manufacturing specifications, which is crucial for the operational efficiency and longevity of machinery.

The importance of line boring cannot be overstated. It directly impacts the performance and reliability of equipment. In scenarios where components become misaligned due to regular wear and tear, line boring comes to the rescue, restoring the machinery’s functionality and preventing costly downtime.

Moreover, the precision that line boring offers ensures that machinery operates at its peak efficiency, reducing wear and tear on other parts and significantly extending the equipment’s life span. This not only saves on repair costs but also optimizes the machinery’s performance, making it an invaluable process in the maintenance routine of heavy equipment.

The technicalities of line boring machines

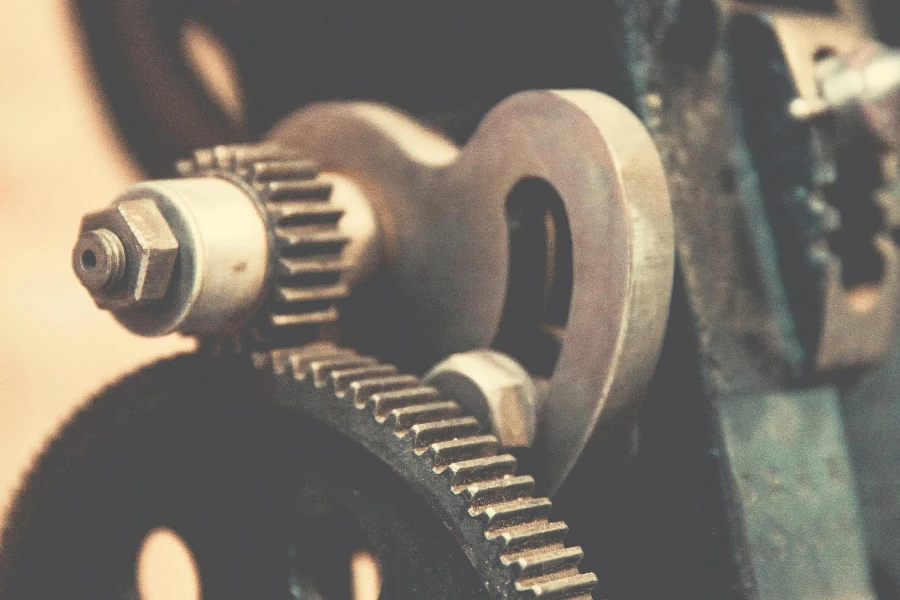

Line boring machines are fascinating pieces of equipment, designed to tackle the demanding task of precision machining. These machines come in various configurations, tailored to different applications, but all share the common goal of restoring worn-out holes to their precise dimensions.

A key feature of line boring machines is their versatility. They can be adapted to work on a wide range of sizes and types of machinery, from small engines to large industrial equipment. This adaptability makes line boring machines an indispensable tool in many repair shops and manufacturing facilities.

Understanding the technical specifications of line boring machines is crucial for optimizing their use. Factors such as the machine’s size, power output, and the precision of its boring bars all play a significant role in determining the quality of the final outcome. The right combination of machine capabilities and operator expertise can achieve unparalleled precision, making it possible to extend the life of machinery significantly.

Common applications of line boring

Line boring finds its application in a myriad of industries, highlighting its versatility and importance. In the automotive sector, line boring is used to repair engine blocks, ensuring that the crankshaft and camshaft bores are perfectly aligned. This process is critical for the engine’s performance and longevity.

In the heavy equipment industry, line boring is essential for repairing large machinery components, such as those found in excavators, bulldozers, and loaders. The process is used to restore the pivot points on these machines, ensuring smooth operation and reducing the risk of premature failure.

Another significant application of line boring is in the aerospace industry, where precision is paramount. Here, line boring is used to repair and maintain critical components of aircraft, ensuring that they meet the stringent standards required for airworthiness. This demonstrates the process’s critical role in maintaining safety and reliability in high-stakes environments.

Challenges in line boring and how to overcome them

Despite its numerous benefits, line boring presents several challenges that operators must navigate. One of the primary challenges is maintaining the precision of the bore throughout the process. This requires not only advanced equipment but also a high level of skill and experience from the operator.

Another challenge is dealing with the varying conditions of the machinery being repaired. Each piece of equipment presents its unique set of variables, from the extent of wear and tear to the specific material properties. Adapting the line boring process to these conditions is crucial for achieving the desired outcomes.

To overcome these challenges, it’s essential to invest in high-quality line boring machines and ensure that operators receive proper training. Additionally, adopting a meticulous approach to the preparation and execution of the line boring process can significantly enhance the quality of the results. This includes careful planning, precise alignment, and continuous monitoring of the process.

Selecting the right line boring service

Choosing the right line boring service is critical for ensuring the success of your repair or maintenance project. The key factors to consider include the service provider’s experience, the quality of their equipment, and their reputation in the industry. A provider with a proven track record of delivering high-quality results is more likely to meet your expectations.

It’s also important to consider the provider’s capacity to handle your specific requirements. This includes not only the technical capabilities of their equipment but also their ability to accommodate your project’s timeline and budget constraints.

Ultimately, selecting the right line boring service comes down to finding a provider that understands your needs and is committed to achieving the best possible outcome for your project. By doing your homework and asking the right questions, you can ensure that your machinery is in good hands.

Conclusion

Line boring is an essential process in the maintenance and repair of machinery, offering a way to restore equipment to its original specifications and extend its life span. Understanding the intricacies of line boring, from the technical aspects of the machines to the challenges and applications, is crucial for anyone looking to leverage this process. By selecting the right line boring service, you can ensure that your equipment remains in top condition, supporting your operations and contributing to your success.