Battery Thermal Management Systems (BTMS) have become a critical technology for modern machines in competing industrial sectors. The 21st century manufacturing sector is a highly competitive arena in which companies must constantly seek to improve system performance and lifetime. Many current systems use battery power and are frequently situated in hostile thermal environments. As we work towards overcoming the energy constraints of the 20th century, there has been a growing focus on energy storage. As a result, battery thermal management has been taking on increasing significance. In this post, we will discuss the importance of BTMS and discuss its applications and cutting-edge developments. This guide aims to help you understand the intricacies of battery thermal management for your next project.

Table of Contents:

– Understanding BTMS and its importance

– Key benefits of implementing BTMS

– Applications of BTMS in modern machinery

– Latest advancements in BTMS technology

– Practical considerations for BTMS adoption

Understanding BTMS and its importance

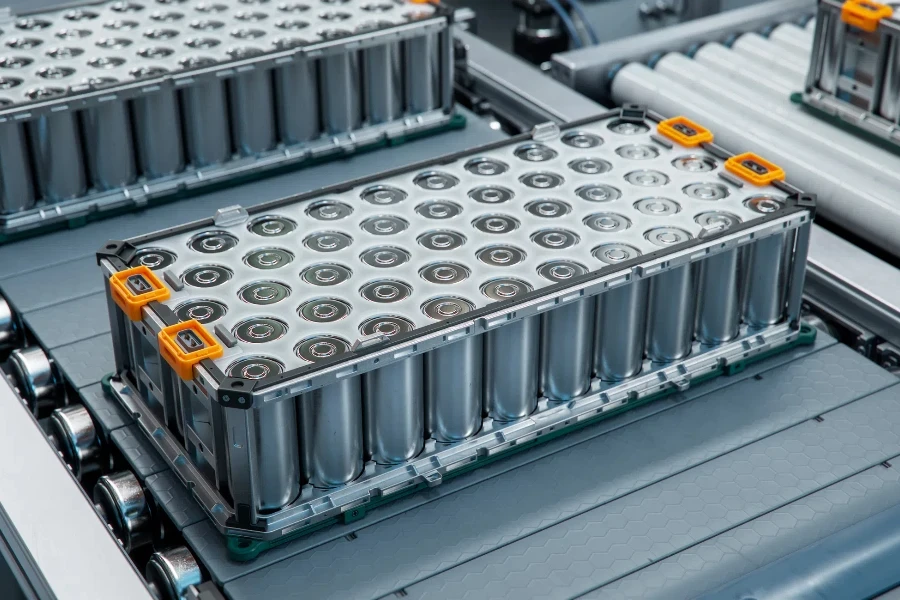

Battery Thermal Management Systems (BTMS) are used to control the temperature of batteries used in machinery. Temperature is a key factor in ensuring the performance, safety and longevity of batteries. If they get too hot or cold, this can affect the efficiency and present risks.

BTMS work by sensing the battery temperature in real time, and either ramping up or down cooling or heating mechanisms, respectively, as necessary to keep the battery operating within its optimal temperature range. This is critical for both maintaining consistent performance and guarding against battery degradation.

In certain industrial sectors that operate at extreme conditions like manufacture or transport, BTMS provides an even stronger role, avoiding thermal runaway – a severe condition where the temperature of the battery abruptly increases and becomes unmanageable.

Key benefits of implementing BTMS

Implementing BTMS offers a range of benefits for machinery operations – from increasing battery life to improving operator efficiency and more. For one, BTMS ensures that the battery doesn’t run too hot or too cold, extending the life of the machine and minimising the amount of replacements or maintenance needed.

Moreover, it enhances safety. Batteries can be dangerous if not controlled, and can endanger both equipment and personnel, if they overheat. BTMS reduces these possibilities.

Furthermore, BTMS improve energy efficiency, and a better energy efficiency means less energy going to waste, which is both cost-effective and less environmentally damaging, especially appealing to industries aiming for more sustainability and less carbon footprint.

Applications of BTMS in modern machinery

The range of applications for BTMS spans many different industries. For the automotive industry, especially the move towards electric vehicles (EVs), BTMS play a vital role in maintaining the health of batteries and ensuring maximum performance and consistent operation. With correct thermal management in EVs, it can increase driving ranges and enhance the overall safety factor. Thus, BTMS now become an indispensable item in this field.

BTMS are used in industrial machinery, such as robotics and heavy equipment, to ensure uptime, and reduce unplanned downtime caused by battery failure, increasing operational effectiveness and reducing operational expenditures.

The renewable energy sector is in turn a beneficiary of BTMS. Solar and wind power installations depend on energy storage systems that require careful thermal management to work properly. Without BTMS, many of the storage units that are the backbone of our renewable energy future wouldn’t work properly.

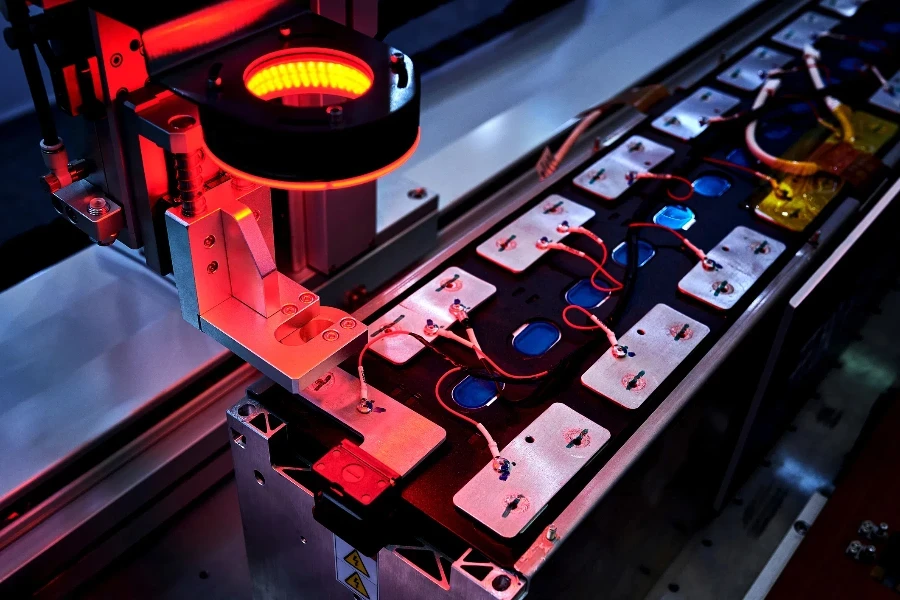

Latest advancements in BTMS technology

BTMS is a fast-moving sector, always with new technologies coming up the pipeline to improve performance and efficiency. One of the latest rising stars in BTMS is the use of phase change materials (PCMs), which dump and absorb heat during phase transitions between solid, liquid and gas. During phase transitions, PCMs can absorb and release heat without the need for complex mechanical systems.

Another innovation is the application of artificial intelligence (AI) and machine learning algorithms to BTMS; these improve predictive maintenance by looking at previous battery performance data to predict when a problem is about to occur so that it can be fixed before it becomes critical. With this level of maintenance, issues are minimised, leading to better reliability and reducing unplanned downtime.

Meanwhile, advancements in battery materials, such as the replacement of liquid electrolytes with solid-electrolytes, are starting to shape BTMS designs. Solid-state batteries emit less heat and have higher energy density, which, in turn, demands more sophisticated thermal management solutions. As solid-state batteries become more widespread, BTMS technology will need to adjust to new demands.

Practical considerations for BTMS adoption

The practicality of implementing BTMS depends on many factors, especially compatibility with machinery currently in use. Is the BTMS going to be able to work with existing systems in a seamless way without disruption? In some cases, it might be necessary to retrofit existing machinery to accommodate a BTMS system. In others, new machinery will need to be purchased.

Price is another factor. While there could be long-term savings as a result of using BTMS, the initial investment is a large one, and the return on investment (ROI) needs to be weighed against things such as increased battery life, lower maintenance costs in the long run, and the improved safety of workers on the platforms.

Second, it’s important to use a supplier and manufacturer with years of experience installing BTMS. Having BTMS expertise means that it will be installed correctly and scaled to your needs, maximising the benefits.

Conclusion

BTMS are the next generation of machinery, providing additional benefits in thermal control, improved safety and operational efficiency. If you know what BTMS are, what advantages they provide and how they are applied, you can make better decisions in incorporating BTMS into your processes. Keep up to date with the latest innovations in BTMS to ensure you have the best thermal management solutions for your machinery.