There is one unheralded tool that is invaluable to every sewer and crafter, and it’s the needle threader. It helps you in threading the needles, especially if you are nearsighted, if you are shaking, if you have bad eyesight, and if the thread is really thin. In this dissertation, I will be discussing needle threaders, talking about how they work, how they are designed, what the uses are, the different types of needle threaders, how to maintain them, and what are the innovative aspects of needle threaders.

Table of Contents:

– Understanding needle threaders

– Types of needle threaders

– How to use a needle threader

– Maintenance and care

– Innovative features in modern needle threaders

Understanding needle threaders

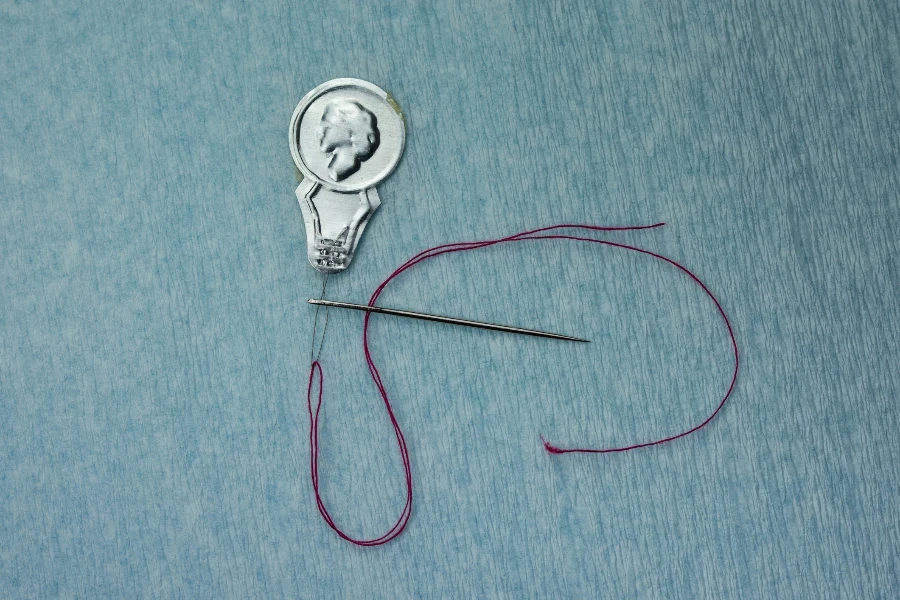

A needle threader is an accessory that links thread to needle, to make sewing a little bit easier by simplifying the often-tedious task of threading the needle. A simple yet ingenious device, it consists of a thin, flexible wire loop that performs the same function as a human eye: it is leveraged by a handle to pull the thread through the eye of the needle. The mechanism itself hasn’t changed radically. When I first began sewing, decades ago, I used the same style of needle threader as my elderly neighbors – a simple, wire gadget that’s still in use today. My paternal grandmother had one, and my mother, an avid seamstress, had two. But to a person whose dexterity or vision is compromised, a needle threader isn’t an accessory, it is a necessity.

So the evolution of needle threaders demonstrates that simple machinery can be beautiful in its design, leading to the development of a machine that can function only through the interplay of tension and leverage. The wire loop strains against the strength of the needle – the narrower the eye, the harder it is to thread – but the tension must be just right: too much, and the tiny wire loop strains and breaks; too little, and it won’t pass through the eye.

Furthermore, needle threaders offer insight into broader patterns related to machinery and technology, as they progressed from manually operated to automated models, while being crafted from materials and designed with parts that make needle-threading faster and more reliable.

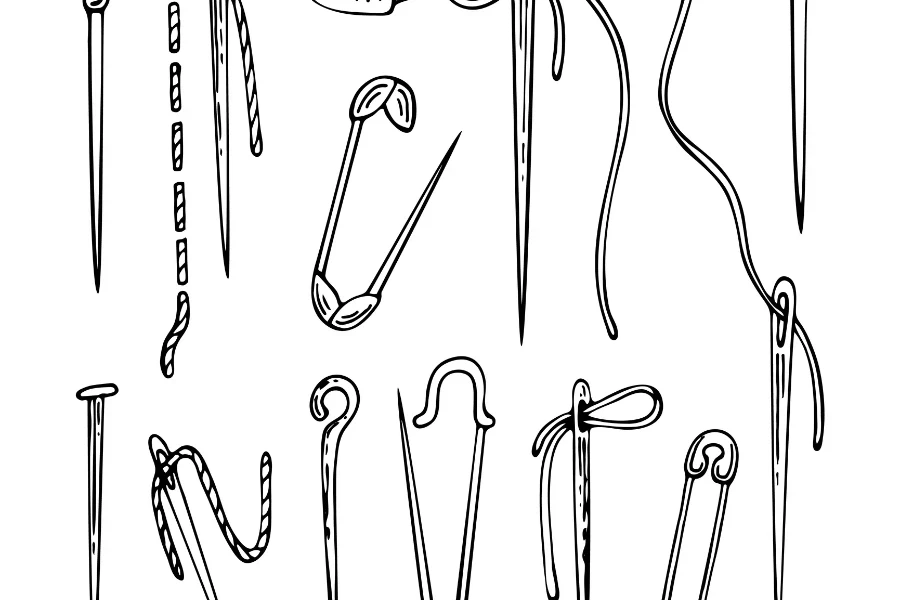

Types of needle threaders

There’s a needle threader for every need (or preference). The manual needle threader is the most typical of all needle threaders. They are cheap and portable, and often come as part of a standard sewing kit. They are what most people think of when they picture a needle threader. The wire loop is generally diamond-shaped with a flat edge for holding thread, and has the appearance of a little coin when the loop is opened.

Conversely, automatic or half-automatic needle threaders, which are built into sewing machines, reflect a blend of function and usability. Half-automatic needle threaders align the thread with the eye of the needle, then apply pressure to poke it through with the slightest of nudges from the operator. This type of needle threader is an example of an ancient custom mating with computerised devices that are useful to all levels of sewists.

Further tiny special-purpose threaders are available for threading embroidery needles with their larger eyes, or for the fine beading needles used in the popular hobby of bead weaving. This variety points to the fact that your needle size, too, will need to be considered when choosing a threader, so that the tool works with, and not against, the rest of your set-up.

How to use a needle threader

Although simple, the needle threader requires some dexterity to use well. For the manual ones, first you run the wire loop through the needle’s eye, and then you run the wire loop through the thread and pull the handle to draw the thread through the needle’s eye. The first time you try a needle threader – whether manual or hand-held – there can be a sense of transformation.

For sewing machines with automatic threaders, it’s even more simple. You put the thread and needle in the right places, then push a lever or button, and the machine pulls and knots and threadholder for you. You save time and frustration, and you’re more likely to want to do it again soon, and be good at sewing.

Regardless of the style of needle threader, it is patience and practice that will perfect one’s use and make sewing easier. Having a familiarity with your tool, and an understanding of its function, can speed up your sewing projects and improve your results.

Maintenance and care

To ensure the longevity and proper functioning of a needle threader, regular upkeep is necessary. The wire loop on a manual threader will need to be checked periodically as it may become bent or broken. Mild cleaning and storage in a dry place can prevent rust and corrosion that would otherwise gradually damage the wire.

For needle threaders that are automatic, maintenance may include removing lint or thread scraps from around the mechanism to ensure its proper function. You should always follow the manufacturer’s instructions for cleaning and servicing, and and servicing, and avoid damaging the machine

Moreover, being aware of these limitations might save your needle threader from misuse (and ruin) by inhibiting you from trying to use it in ways that it wasn’t designed for, such as trying to force the wire through a needle eye too small for it, or using it to work with thread that is too small for the wire.

Innovative features in modern needle threaders

The latest needle threaders embody the pursuit of ease of use and efficiency Still, we found needle threaders with innovative features such as LED lights for better visibility, ergonomic contours for ease of grip and comfort, and reinforced wires for better durability. Manufacturers have further improved the needleguide/eye of the needle threader so that it will work effectively even with thin or very fine needle points and high tension thread. Needless to say, all of these innovations make the handling and use more efficient, and they improve the quality of the product so that users can derive greater benefits.

Still, at a more fundamental level, the adoption of needle threaders by digital sewing machines with touch-screen programming and customisable settings – and their further incorporation into dedicated accessories such as darning eggs – reanimates these skills, permeating new forms of practice with the promise of digital technology. As a result, the creative possibilities are legion.

Looking to the future, we can anticipate that the evolution of needle threaders will follow the tendency of new machinery and technologies to provide increasingly sophisticated responses to the age-old problem of threading needles.

Conclusion

The needle threader is one of the most basic tools among all the sewing accessories, nevertheless, it plays an important role. Its structure is simple and intuitive, and its function is clear and straightforward. We can see that there are different types of needle threaders to address the same problem. With the use of a needle threader, the sewing experience will be much better. If one knows how to use and maintain a needle threader, and how to choose the proper needle threader, that would guarantee a good sewing experience. In the future, with the developing technology, needle threader will have more features and better functionality. With the improvement of needle threader, it will become much easier and more convenient for sewing. It will be an affordable, effective tool for all the people.