The realm of machinery constantly evolves, introducing more efficient and precise methods to achieve the desired results in manufacturing and metalworking. Among these innovations, the Blanchard grinder stands out for its unique approach to surface grinding. This article delves into the core aspects of Blanchard grinders, shedding light on their functionality, applications, advantages, maintenance tips, and the future of grinding technology. By exploring these facets, we aim to provide a comprehensive understanding of how these machines contribute to the industry’s advancement.

Table of Contents:

– What is a Blanchard grinder?

– Key applications of Blanchard grinders

– Advantages of using Blanchard grinders

– Maintenance tips for Blanchard grinders

– The future of grinding technology

What is a Blanchard grinder?

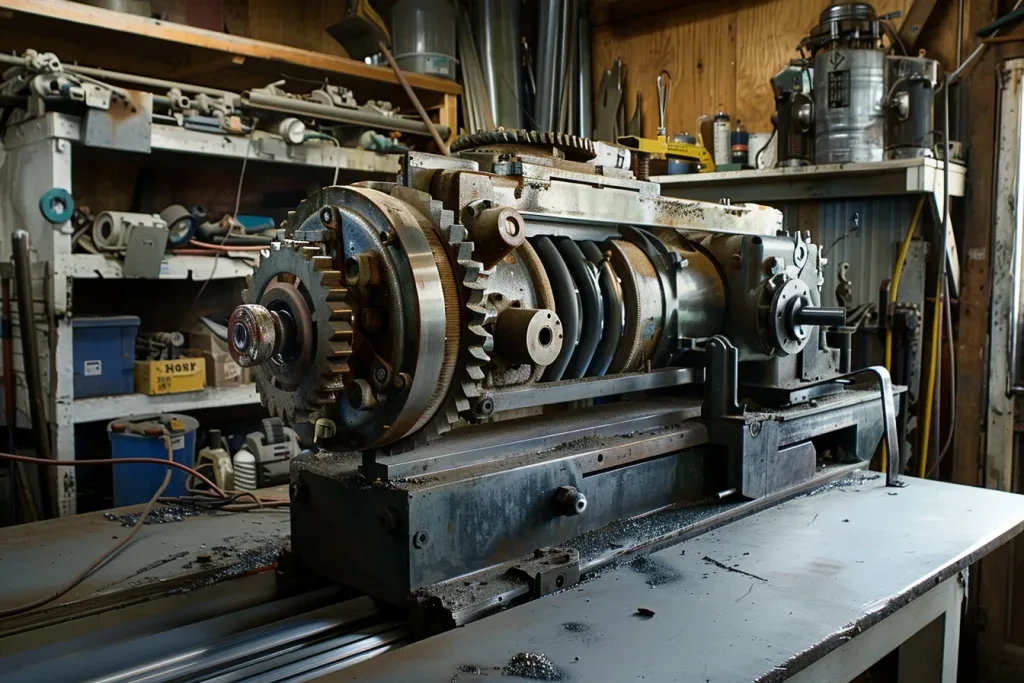

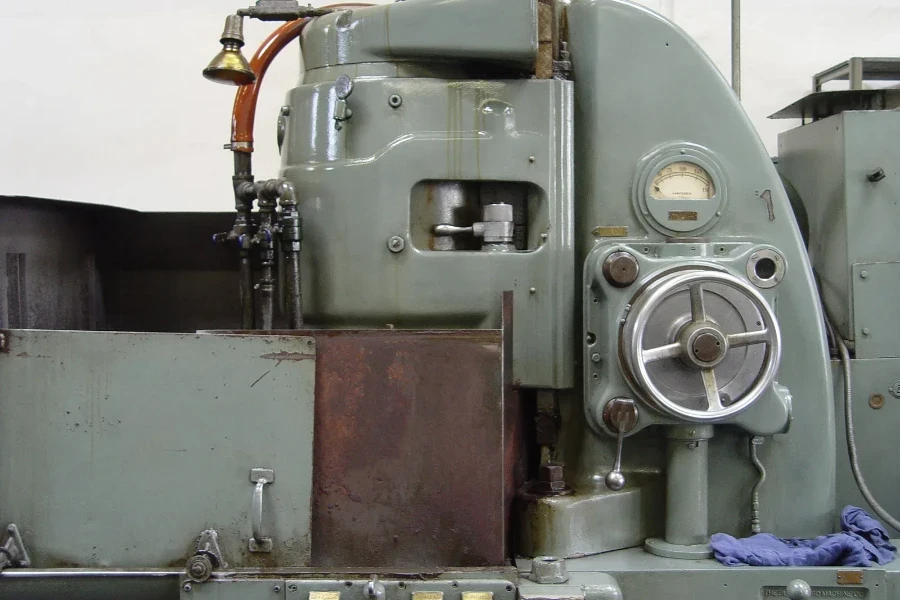

A Blanchard grinder, often regarded as a rotary surface grinder, employs a magnetic chuck to hold workpieces for grinding over the surface. The grinder’s design allows for a distinctive grinding process, where the grinding wheel rotates against the workpiece, achieving a precise and smooth finish. This section explores the technical specifics of how Blanchard grinders operate, their design features, and the types of grinding wheels used, providing readers with a solid foundation on the machine’s mechanics.

Key applications of Blanchard grinders

Blanchard grinders excel in various industrial applications, from metalworking to manufacturing parts for aerospace and automotive industries. This versatility stems from their ability to handle large parts and achieve precise tolerances and surface finishes. Here, we’ll discuss the range of materials that can be processed with Blanchard grinders and highlight specific industries that benefit most from its use. By understanding its applications, businesses can better assess how a Blanchard grinder can fit into their operations.

Advantages of using Blanchard grinders

The adoption of Blanchard grinders brings numerous benefits, including enhanced precision, efficiency, and cost-effectiveness in material removal processes. This section outlines the key advantages, such as the ability to quickly remove large amounts of material, achieve uniform surface finishes, and reduce operational costs. Through real-world examples and comparisons, we’ll illustrate how these benefits translate into improved production outcomes and competitive advantages for businesses.

Maintenance tips for Blanchard grinders

Maintaining a Blanchard grinder in top condition is crucial for ensuring its longevity and performance. This part of the article provides practical maintenance tips, covering regular cleaning routines, inspection checklists, and common wear-and-tear issues. By following these guidelines, operators can prevent downtime, extend the machine’s lifespan, and maintain optimal grinding results. Additionally, we’ll touch on safety practices to ensure a secure working environment for machine operators.

The future of grinding technology

As the machinery industry continues to innovate, the future of grinding technology looks promising, with advancements aimed at increasing precision, automation, and sustainability. This section speculates on how Blanchard grinders might evolve, incorporating AI, IoT, and green manufacturing practices. By staying informed about these trends, businesses can prepare for the shifts in grinding technology and remain competitive in the ever-changing landscape of manufacturing.

Conclusion:

Blanchard grinders play a pivotal role in the machinery industry, offering unmatched efficiency and precision in surface grinding. Understanding their operation, applications, benefits, and maintenance can significantly impact production outcomes. As technology advances, staying abreast of the latest developments in grinding processes will ensure that manufacturers can continue to leverage these powerful machines’ full potential. Embracing the future of grinding technology will be key to innovation and success in the field.