Craftsman air compressors have become a staple in both professional and home garages, offering a blend of reliability, efficiency, and versatility. This article delves into the critical aspects of these machines, helping you understand their operation, maintenance needs, and how to select the right model for your tasks. Whether you’re a seasoned mechanic or a DIY enthusiast, a deeper look into the world of craftsman air compressors reveals how they can enhance your projects and productivity.

Table of Contents:

– Understanding the mechanics of a craftsman air compressor

– Key features to look for in a craftsman air compressor

– Maintenance tips for your craftsman air compressor

– How to select the right craftsman air compressor for your needs

– The role of craftsman air compressors in modern workshops

Understanding the mechanics of a craftsman air compressor

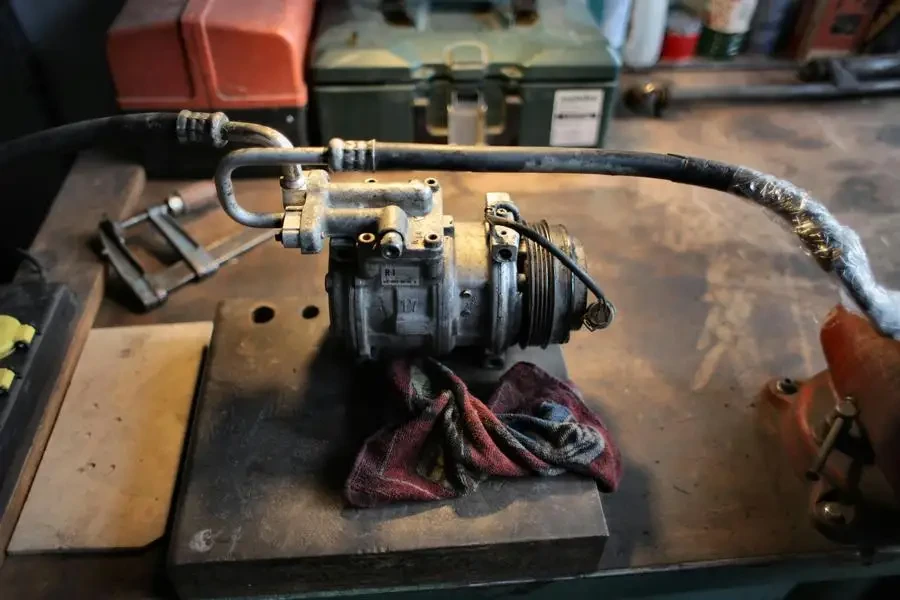

Air compressors, particularly those crafted for precision and durability, operate on a simple yet fascinating principle. They convert power into potential energy stored in pressurized air, a concept that might seem straightforward but involves intricate engineering. The heart of a craftsman air compressor is its motor, which drives a pump that compresses air into a storage tank. As the tank’s pressure reaches its engineered upper limit, the compressor shuts off, readying the stored pressurized air for use.

The variety of pumps used—whether piston, diaphragm, or rotary screw—plays a crucial role in determining the compressor’s application, from inflating tires to powering pneumatic tools. Understanding these mechanics not only satisfies curiosity but also empowers users to make informed decisions, ensuring they have the right tool for their projects.

Key features to look for in a craftsman air compressor

When navigating the vast market of air compressors, knowing the key features that align with your needs can significantly narrow down your options. Firstly, the capacity and pressure ratings of the compressor are paramount. These determine how much air the compressor can store and at what pressure, directly impacting its ability to power your tools effectively.

Noise level is another critical factor, especially for indoor use or in noise-sensitive environments. Some models are designed with noise reduction in mind, offering a quieter operation without sacrificing performance. Additionally, the size and portability of the compressor are essential considerations if you need to move it around your workshop or transport it to various job sites.

Maintenance tips for your craftsman air compressor

Regular maintenance is the backbone of ensuring your air compressor runs efficiently and lasts longer. Draining the tank after each use prevents rust and corrosion caused by moisture accumulation, a simple step that can significantly extend the lifespan of your compressor. Checking and replacing air filters regularly also plays a crucial role in maintaining air quality and compressor performance.

Lubrication is another maintenance aspect that cannot be overlooked. Depending on your compressor type, ensuring it is adequately lubricated can prevent wear and tear on moving parts, ensuring smooth operation. These maintenance tips, while basic, are fundamental to getting the most out of your investment.

How to select the right craftsman air compressor for your needs

Selecting the right air compressor involves a careful consideration of your specific needs and the tasks you intend to accomplish. For light-duty tasks such as inflating tires or powering small air tools, a portable, smaller-capacity compressor might be sufficient. However, for more demanding applications like running high-power pneumatic tools or spray painting, you’ll need a compressor with a larger tank and higher pressure capabilities.

Understanding the CFM (cubic feet per minute) requirement of your tools is crucial in this selection process. Ensuring your compressor can provide a consistent airflow that meets or exceeds this requirement is key to efficient and effective tool operation. Additionally, consider the power source available in your workspace; while electric compressors are common, gas-powered models offer portability and power but require proper ventilation.

The role of craftsman air compressors in modern workshops

The versatility of craftsman air compressors has cemented their role as indispensable tools in modern workshops. From automotive repair and woodworking to metal fabrication and construction, these machines support a wide range of applications, driving efficiency and productivity. Their ability to power an extensive array of tools—from wrenches and grinders to sanders and paint sprayers—makes them a central piece of equipment in any workshop.

Moreover, the evolution of air compressor technology, with improvements in efficiency, durability, and noise reduction, has expanded their utility beyond traditional settings. Today, craftsmen, hobbyists, and DIY enthusiasts alike rely on these compressors to bring their creative visions to life, proving that the right tools not only facilitate work but inspire innovation.

Conclusion: Craftsman air compressors embody the blend of innovation, versatility, and reliability that modern workshops require. Understanding the mechanics, key features, and maintenance needs of these compressors, along with how to select the right model, empowers users to maximize their productivity and creativity. Whether for professional applications or personal projects, a craftsman air compressor is a valuable investment in your craft.