Tie down straps are an essential tool in the world of vehicle parts and accessories, offering a blend of strength, versatility, and safety. Whether you’re transporting cargo, securing equipment, or ensuring the stability of a vehicle, understanding the nuances of these straps can significantly enhance your safety measures. This article delves into the five key aspects users should know about tie down straps, breaking down their complexities into practical insights.

Table of Contents:

1. Understanding the different types of tie down straps

2. How to select the right tie down strap for your needs

3. The correct way to use tie down straps

4. Maintenance and care for longevity

5. Common mistakes to avoid with tie down straps

Understanding the different types of tie down straps

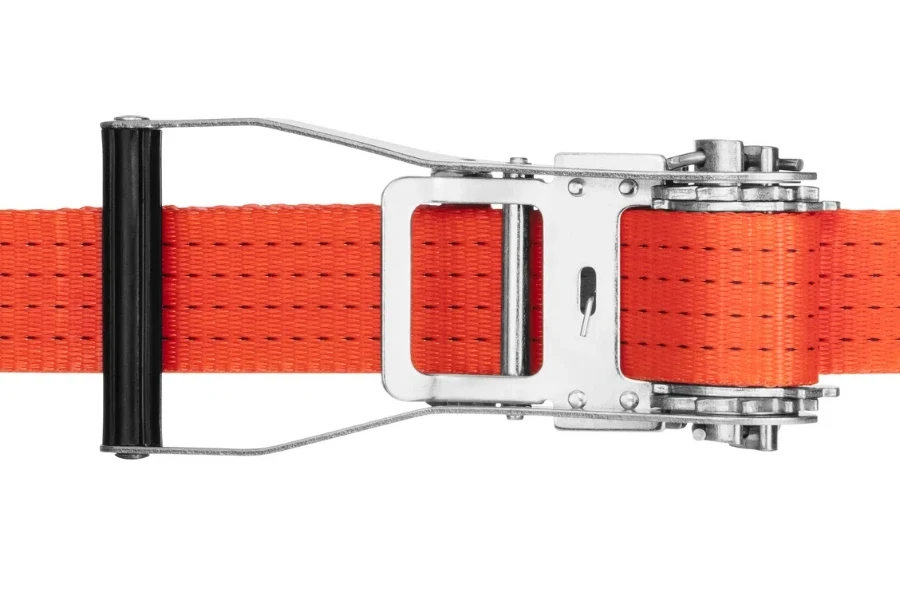

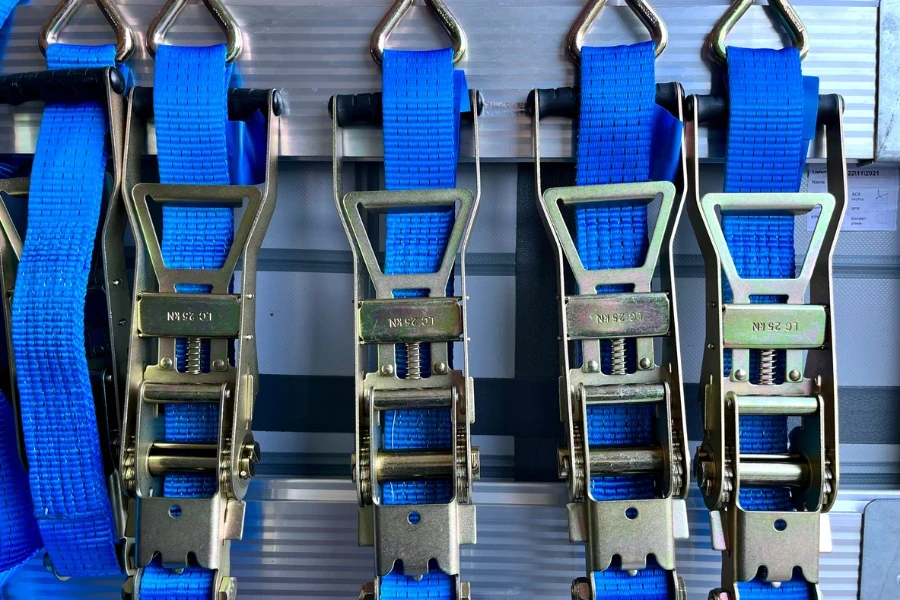

Tie down straps come in various materials, lengths, and with different locking mechanisms, each suited to specific tasks. Cam buckle straps, for example, are ideal for lighter loads and can be easily tightened by hand, offering a quick and efficient way to secure cargo. Ratchet straps, on the other hand, are designed for heavier loads, providing a mechanism to apply significant tension with minimal effort. The material of the strap, typically polyester or nylon, also plays a crucial role in its durability and suitability for different environmental conditions.

How to select the right tie down strap for your needs

Selecting the right tie down strap involves understanding the weight and nature of the cargo, the conditions it will be exposed to, and the method of transportation. For heavy-duty applications, a ratchet strap with a high break strength and durability is essential. For everyday use or lighter loads, a cam buckle strap may suffice. It’s also important to consider the length of the strap, as having too much or too little can compromise the security of the load.

The correct way to use tie down straps

Using tie down straps correctly is paramount for safety. The process begins with inspecting the strap for any signs of wear or damage. Once deemed safe, the strap should be attached to secure anchoring points on the vehicle or trailer. The cargo should be evenly distributed and the strap threaded through the ratchet mechanism or cam buckle, then tightened to ensure there is no slack. It’s crucial to regularly check the tension of the strap during transportation, as vibrations can cause it to loosen.

Maintenance and care for longevity

Proper maintenance of tie down straps can significantly extend their lifespan. After each use, straps should be inspected for damage, such as cuts, frays, or weakened areas. Cleaning the straps with mild soap and water, especially after exposure to harsh conditions, can prevent degradation of the material. Storing the straps in a dry, cool place away from direct sunlight will also protect them from environmental damage and prolong their usability.

Common mistakes to avoid with tie down straps

Many users inadvertently compromise their safety by making common mistakes with tie down straps. Overloading a strap beyond its rated capacity can lead to failure, as can using a damaged or worn strap. Failing to secure the strap properly, allowing too much slack, or not checking the strap during transport can also result in cargo shifting or becoming unsecured. Understanding these pitfalls and actively working to avoid them is crucial for safe and effective use of tie down straps.

Conclusion:

Tie down straps are a fundamental component of vehicle safety and cargo management, offering a reliable solution to secure loads during transportation. By understanding the different types of straps, selecting the right one for your needs, using them correctly, and maintaining them for longevity, you can ensure the safety of your cargo and others on the road. Avoiding common mistakes further enhances the effectiveness of these versatile tools, making them an indispensable part of vehicle safety practices.