Laser cutter machines can be seen as the epitome of perfection when it comes to any machine because it provides precision, speed and versatility in cutting materials unlike any other machine in the world. This guide explains how laser cutters work, how it is used, and how much it costs, as well as looking at the top-rated laser cutters available in the market.

Table of Contents:

– What is a laser cutter machine?

– How do laser cutter machines work?

– How to use a laser cutter machine

– How much does a laser cutter machine cost?

– Top laser cutter machines

What is a laser cutter machine?

A laser cutter machine is an electrical advanced device that work with a laser beam. It is designed to perform cutting, engraving, or marking on a surface. Laser cutter machines used in a lot of industries because of their accuracy and efficiency. Cutting, engraving and marking on variety of material have become a lot easier using laser cutter machines .Laser cutter machines can be used on a huge variety of materials including metal, plastic, wood and glass. Laser cutting technology has evolved over time giving rise to laser cutter machines.

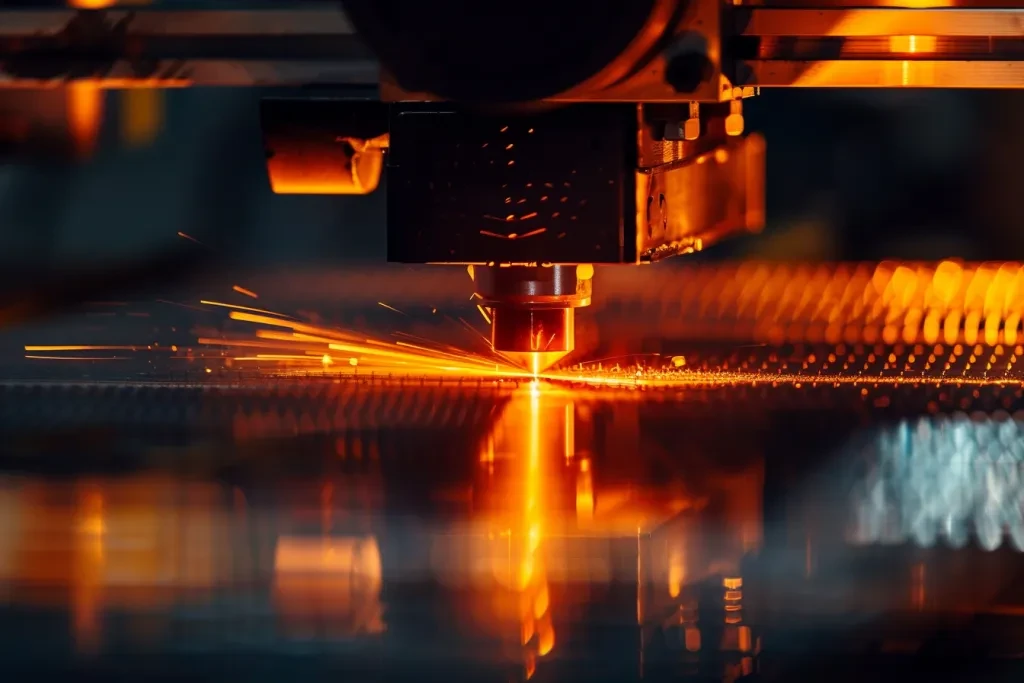

A laser cutter transfers energy to a material using a focused beam of light. The light hits its target, and the energy is absorbed by the material, causing initial melting, burning or vaporisation, and eventually cutting through the material. Everything happens in a remote, vacuum-like environment with no contact. Such highly controlled conditions have the potential to produce complex patterns with exquisite detail, resulting in little to no waste. The key here is remote, contactless cutting. Equipment can be applied safely to a material through laser energy, and the contamination issue becomes moot.

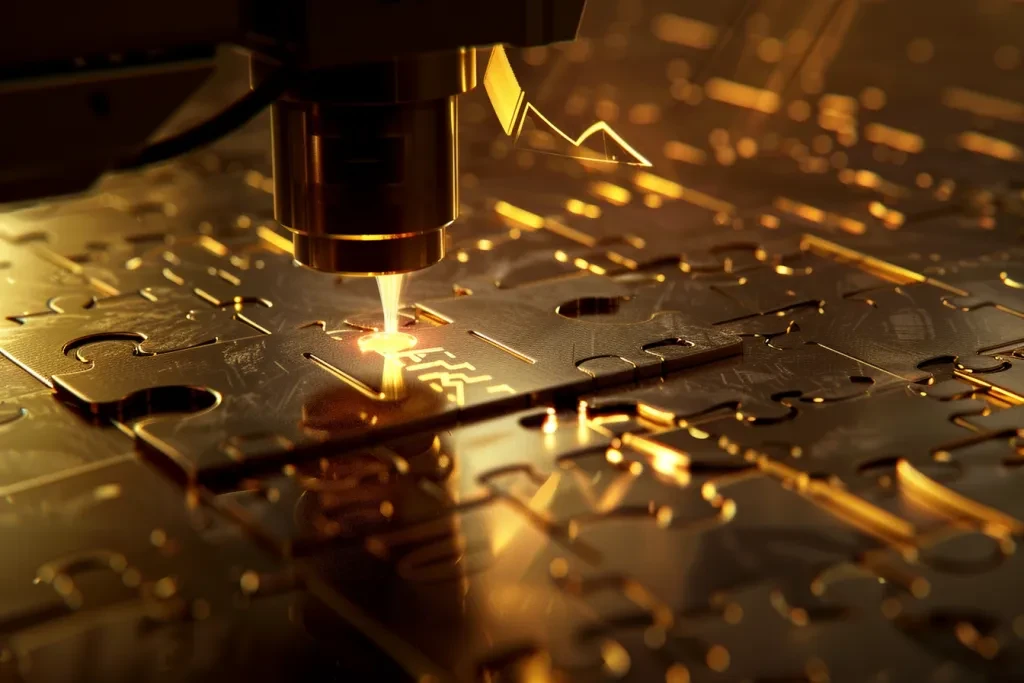

The laser cutter’s versatility also enables it to engrave or etch a pattern or design into the surface of a material rather than simply cutting it away. On that point, a designer or other person with an artistic flair could easily draw or finalise a design with any graphics or design software and have the design transferred onto a material.

How do laser cutter machines work?

Its main part is the laser generated in a laser tube filled with gas or solid-state media. When current is applied to laser tube, it generates a beam of coherent light. Multiple mirrors facilitate the generation process and finally the light is focused into a fine point with a focusing lens. The focused beam is then fired to the material to introduce the intense heat and energy.

A computer controls the cutting line of a laser beam according to digital drawings or patterns – a computer numerical control (CNC) system – which can move the cutting line to precise fractions of a millimetre, and can perform cuts at speeds and power levels that depend on the material and the outcome. Laser cutters are incredibly versatile.

A cooling system is also a must to remove heat, otherwise the device simply stops working. Water-based systems are used for high cutting powers, while air cooling is more common for lower laser powers. The proper maintenance of these elements and the calibration of the laser, the optical components and the mechanics of the machine are necessary to ensure a longer life of the laser cutter and its components.

How to use a laser cutter machine

Preparing to start up the laser cutter machine requires the design to be ready. This is normally some sort of image that has been defined in a special program. That program will convert the digital graphics into a language the laser machine can understand. Once it has been uploaded, the software will tell the laser signal when, where, and how to follow the predetermined parameters of the design.

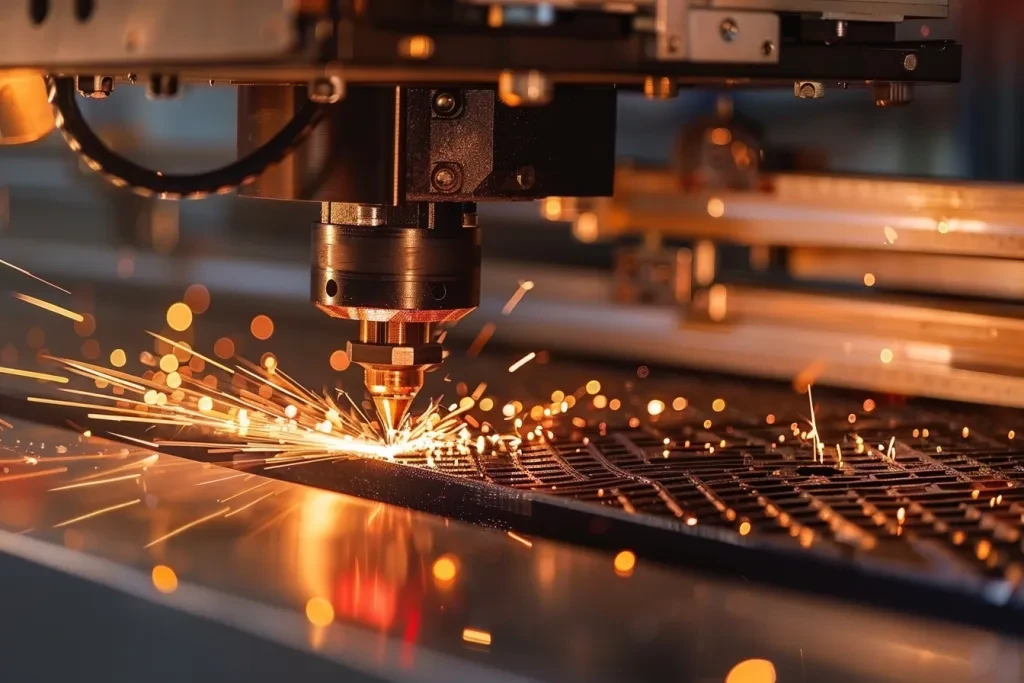

Proper material prep is also required. The material to be cut must be clamped firmly to the cutting bed to stop it from moving while it is being cut. Different materials have different recipes, such as power, speed and focus, to yield good results. Often, the recipe must be found by trial and error or by checking the material setting provided by the machine manufacturer.

Ensuring personnel safety is the priority when using laser cutters; the operators should always wear protective eyewear to block the harmful laser radiation and minimise fire risks since the laser beam can reach temperatures of millions of degrees celsius. The ventilation system maintained in the cutting area is also important, since cutting can easily produce fumes and smoke that are hazardous to humans.

How much does a laser cutter machine cost?

The price of a laser cutter can differ based on the size, the amount of power it uses, and the features installed. Depending on the machine, it could start from a few hundred dollars for a small entry-level machine up to tens of thousands of dollars as some machines used in industries are designed for professional and heavy use.

The price depends on the kind of laser (CO2 laser, fibre laser, crystal laser), the power of the laser (watt), the size of the cutting bed and the number of additional features (such as autofocus, integrated cooling system, advanced software). The higher the investment in quality machines, the better the results, the higher reliability and lower maintenance costs.

A laser sign cutter can help a business increase productivity and enhance capabilities, but the cost of the equipment factored into that investment must be carefully considered. Businesses can find financing and even leasing options to reduce the initial cost of a laser cutter if the savings outweigh the overall investment.

Top laser cutter machines

There are a few flagship companies who manufacturer great, reliable, workhorse laser cutter machines. The first is the Glowforge Plus, a machine targeted to hobbyists and small businesses. This workable, plug-and-play machine – one of the most popular we have ever seen with cloud-based software that anyone can access from their phone – is extremely versatile and can cut various different materials. If you need more higher quality, industrial–grade power, the Epilog Laser Fusion Pro series comes with industrial-grade potency, including quicker cutting speeds and larger work areas.

Another entry is the Dremel Digilab LC40, an affordable and reliable model that is great for teachers, small businesses or serious hobbyists. It has the intuitive yet powerful software you need to get perfect prints, and high-quality components that will ensure good performance for several years.

For the more traditional industrial use, the Trumpf TruLaser series offers high speed cutting and a choice of automation options, while also offering millimetre-precision, to the point where it’s possible to cut metal to a thickness of only one millimetre. For metalworkers seeking to stay, or get ahead, of the competition with state-of-the-art laser cutting techniques, Trumpf truly has the market cornered.

Conclusion: Laser cutter machines hold great potential for precision, speed, and versatility in a wide variety of materials and applications. Understanding how do laser cutters work, how to use one, and how much does a laser cutter cost can help businesses and individuals make informed decisions regarding if and when to invest in such technology. With the right machine, users can have a whole new world of creativity and productivity opened up before them.