In the world of knife making, precision, efficiency, and the quality of the finish are paramount. Enter the knife makers belt sander, a pivotal tool in the arsenal of both amateur and professional blade smiths. This article delves deep into the mechanics, usage, and benefits of this indispensable machinery, guiding you through its costs and top models on the market.

Table of Contents:

– What is a knife makers belt sander?

– How does a knife makers belt sander work?

– How to use a knife makers belt sander

– How much does a knife makers belt sander cost?

– Top knife makers belt sanders

What is a knife makers belt sander?

A knife makers belt sander is a specialized tool designed for shaping, sharpening, and finishing knives with precision and efficiency. Unlike generic belt sanders, these machines cater specifically to the unique needs of knife making, offering features like variable speed controls, adjustable belts, and supportive frames for accurate work. They range from compact, benchtop models suitable for hobbyists to industrial-grade machines for professional workshops. The core of their design lies in their ability to remove material quickly while providing the user with control over the shaping process, making them indispensable in the creation of high-quality knives.

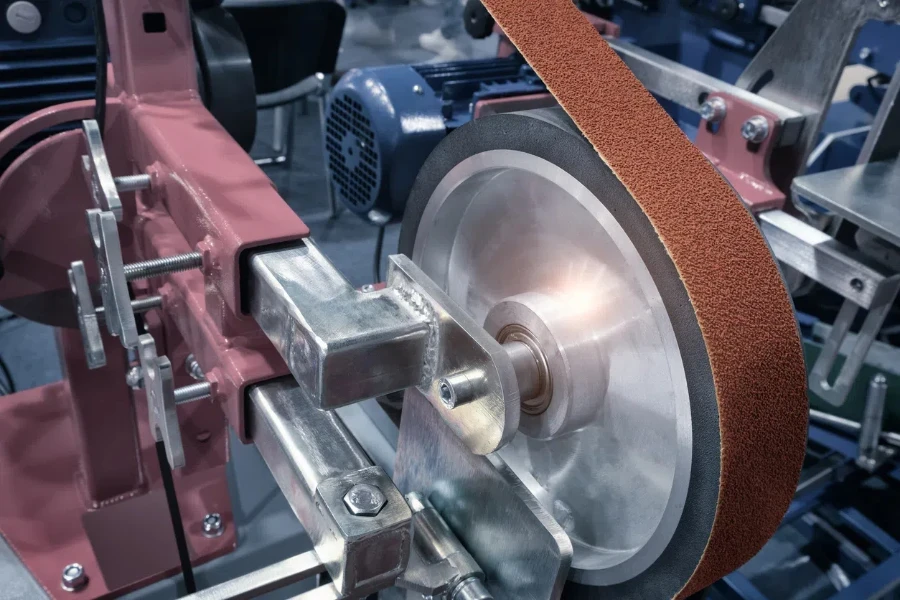

How does a knife makers belt sander work?

At its heart, a knife makers belt sander operates by using a continuously moving abrasive belt to grind and shape metal. The motor powers the belt around two or more pulleys, creating a loop that effectively sands away metal with precision. The speed at which the belt moves can often be adjusted, allowing for delicate work on finer details or faster removal of material when needed. Additionally, many models feature adjustable platens or work rests that can be tilted and locked at various angles, enabling the craftsman to work on different facets of the blade with ease. Dust collection systems are also a common feature, helping to keep the workspace clean and the air quality safe.

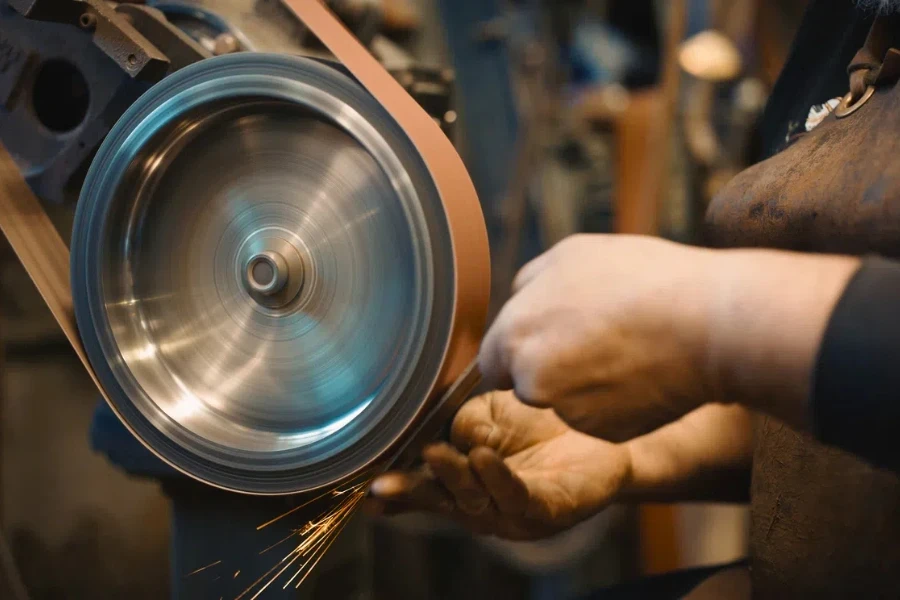

How to use a knife makers belt sander

Using a knife makers belt sander requires a blend of skill, patience, and safety precautions. Before starting, it’s crucial to don appropriate safety gear, including eye protection, ear protection, and a dust mask. Begin by selecting the correct belt grit for your task – lower grits for material removal and higher grits for finishing touches. Adjust the belt tension and tracking to ensure smooth operation. When shaping a blade, use steady, controlled movements to press the metal against the belt, keeping the blade at the desired angle to achieve the correct bevel. It’s important to frequently dip the blade in water to prevent overheating, which can lead to loss of temper and strength in the steel. With practice, users can achieve precise, consistent results, making the knife makers belt sander an invaluable tool in the knife making process.

How much does a knife makers belt sander cost?

The price of a knife makers belt sander can vary widely based on its size, features, and manufacturer. Entry-level models suitable for hobbyists and beginners can start as low as $100 to $200, offering basic functionality and a good starting point for those new to knife making. Mid-range models, which provide more power, better durability, and additional features like variable speed controls, can range from $500 to $1,000. For professional knife makers requiring the highest level of precision and efficiency, high-end models can cost upwards of $2,000 to $3,000, equipped with advanced features like larger belts, more powerful motors, and enhanced dust collection systems. Ultimately, the investment in a knife makers belt sander should be guided by the user’s level of expertise, frequency of use, and specific needs in their craft.

Top knife makers belt sanders

When it comes to selecting the best knife makers belt sander, several standout models come to mind. The Grizzly Industrial G1015 is a popular choice among hobbyists for its affordability and solid performance. It features a 1” x 30” belt size and a ⅓ HP motor, making it suitable for smaller projects. For those seeking more power and versatility, the Kalamazoo 1SM is a robust option, with its 1” x 42” belt and ability to handle both metal and wood with ease. At the pinnacle of professional-grade equipment, the Burr King 760 is a top contender, boasting a 1.5 HP motor, a 2” x 60” belt, and a wide range of speed settings for ultimate control. These models exemplify the diversity and capability of knife makers belt sanders available on the market, catering to various needs and budgets.

Conclusion:

The knife makers belt sander is a cornerstone tool in the art of knife making, offering unparalleled precision, versatility, and efficiency in shaping and finishing blades. Whether you’re a budding hobbyist or a seasoned professional, understanding how these machines work, how to use them properly, and what options are available is crucial in selecting the right sander for your needs. With the right equipment and technique, the possibilities in knife making are virtually limitless, allowing craftsmen to push the boundaries of creativity and craftsmanship in their work.