The evolution of woodworking has taken a significant leap with the advent of CNC wood cutting machines. These sophisticated devices combine precision, efficiency, and versatility, revolutionizing how woodcraft is approached. From intricate designs to mass production, understanding the capabilities of CNC machines opens up a world of possibilities for enthusiasts and professionals alike.

Table of Contents:

– What is a CNC wood cutting machine?

– How do CNC wood cutting machines work?

– How to use a CNC wood cutting machine

– How much does a CNC wood cutting machine cost?

– Top CNC wood cutting machines

What is a CNC wood cutting machine?

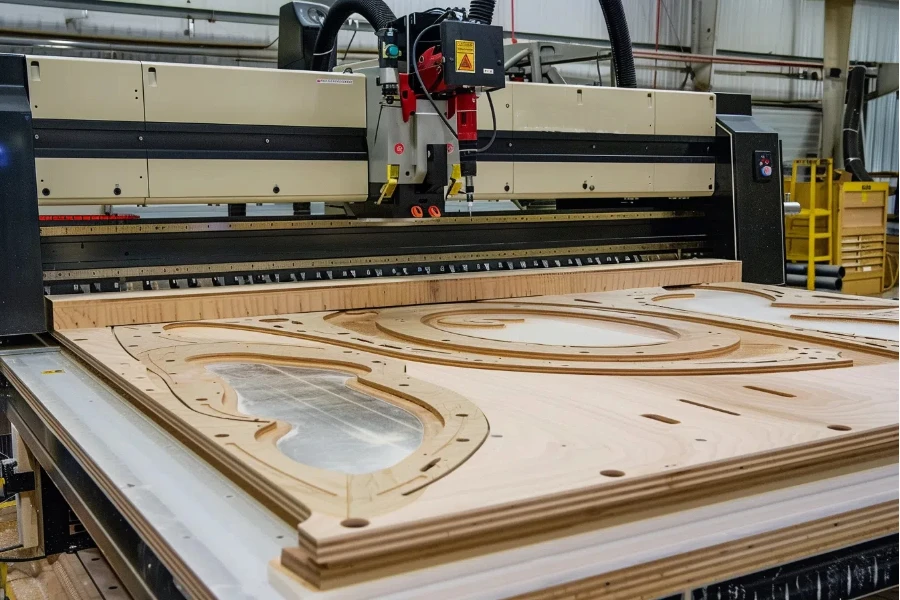

A CNC (Computer Numerical Control) wood cutting machine is a marvel of modern engineering designed to transform raw wood into intricate designs, precise cuts, and detailed finishings. At its core, it operates under the guidance of computer-controlled systems, allowing for the automation of complex and repetitive tasks with unparalleled accuracy. These machines range from small, desktop models suitable for hobbyists to industrial-grade machines capable of handling large-scale production needs. The versatility of CNC wood cutting machines makes them indispensable tools in the fields of carpentry, furniture making, and even sculptural art.

How do CNC wood cutting machines work?

The magic of a CNC wood cutting machine lies in its detailed and precise control system. It starts with a designer creating a digital blueprint using CAD (Computer-Aided Design) software. This design is then converted into a CNC-compatible file format, detailing the machine’s path during the cutting process. The heart of the machine, the router or spindle, equipped with various cutting tools, then interprets these instructions to cut, carve, and shape the wood according to the specified design. Advanced models incorporate features like multiple axes of movement, allowing for the creation of complex three-dimensional shapes with smooth finishes and intricate details.

How to use a CNC wood cutting machine

Using a CNC wood cutting machine begins with the preparation of the design and the setup of the machine. After creating a design in CAD software and converting it into a machine-readable format, the next steps involve securing the wood piece onto the machine’s bed, selecting the appropriate cutting tool, and setting the correct parameters such as speed, depth, and path of the cut. Once everything is in place, the machine operator initiates the cutting process, closely monitoring the machine to ensure everything runs smoothly. Regular maintenance and calibration of the machine are crucial to ensure consistent results and prolong the lifespan of the machine.

How much does a CNC wood cutting machine cost?

The cost of a CNC wood cutting machine can vary widely depending on its size, capabilities, and the specific features it offers. Entry-level models suitable for hobbyists and small workshops can start from a few thousand dollars, offering basic functionality for smaller projects. Mid-range models, offering greater power and versatility for more complex tasks, can range from $10,000 to $25,000. Industrial-grade machines designed for heavy-duty use and precision on a large scale can easily exceed $50,000. When considering the purchase of a CNC wood cutting machine, factors such as the intended use, required precision, and available budget should guide the decision-making process.

Top CNC wood cutting machines

The market offers a plethora of options when it comes to CNC wood cutting machines, each with its own set of features and capabilities. Some of the top contenders include the ShopBot PRSalpha for its robust construction and versatility, the Axiom Precision AR8 Pro+ for its exceptional accuracy and ease of use, and the Laguna Tools SmartShop M series for its advanced features and industrial-grade performance. These machines represent the pinnacle of CNC technology, offering users the ability to create detailed and precise woodwork with relative ease.

Conclusion:

CNC wood cutting machines are transformative tools in the world of woodworking, offering precision, efficiency, and versatility that manual techniques simply cannot match. Whether you are a hobbyist looking to explore the realms of creative woodworking or a professional aiming for high-efficiency production, understanding the workings, usage, and costs associated with these machines can help you make an informed decision. With the right CNC wood cutting machine, the possibilities for what you can create are virtually limitless.