In the realm of 3D printing, resin 3D printers have emerged as a cornerstone of precision and quality, catering to a wide range of applications from prototyping to final product manufacturing. This article delves into the intricacies of resin 3D printing, exploring the technology’s capabilities, benefits, and the considerations users must weigh before diving in. By breaking down complex concepts into digestible explanations, we aim to provide a comprehensive understanding of resin 3D printers, empowering you with the knowledge to leverage this technology effectively.

Table of Contents:

– Understanding resin 3D printing technology

– The benefits of using a resin 3D printer

– Common applications of resin 3D printers

– Key considerations before purchasing

– Maintenance and safety tips

Understanding resin 3D printing technology

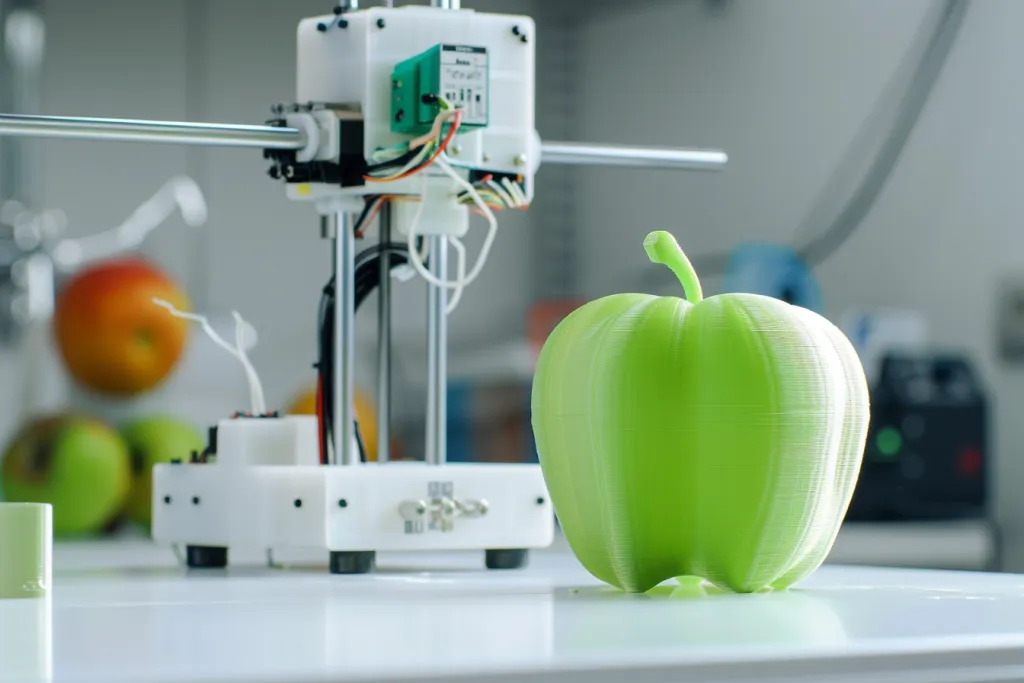

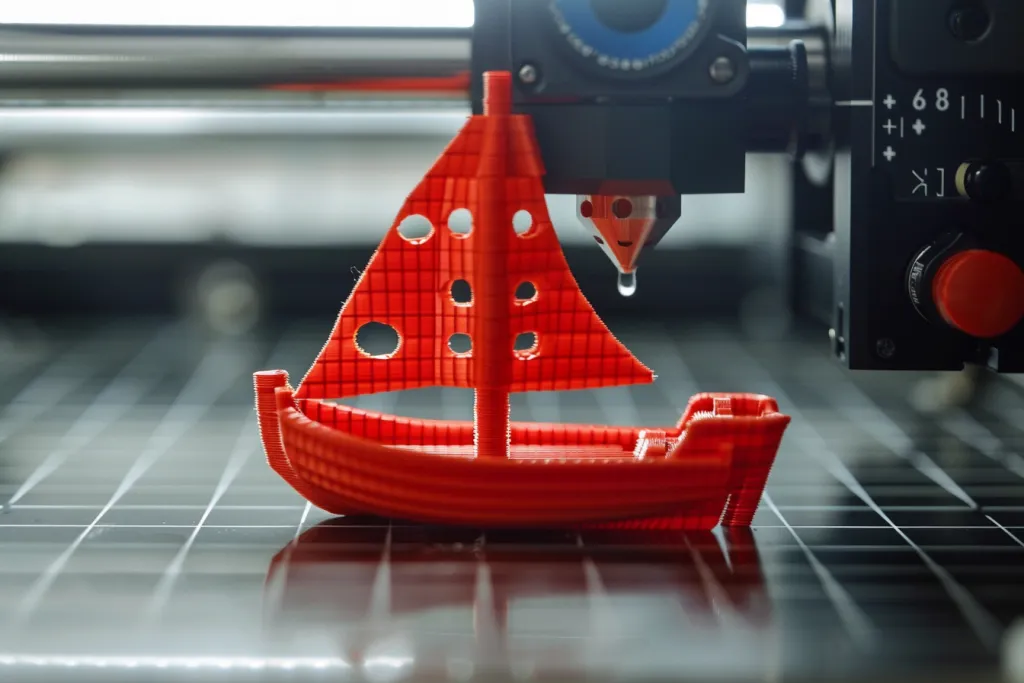

Resin 3D printing, also known as Stereolithography (SLA), stands out for its ability to produce objects with incredibly high resolution and accuracy. The process involves curing liquid photopolymer resin into solid objects, layer by layer, using ultraviolet (UV) light. This method allows for intricate details and smooth finishes that are often challenging to achieve with other types of 3D printing technologies.

The core of resin 3D printing technology lies in its precision. The UV laser focuses on specific points in the resin vat, hardening the resin precisely where the object is to be formed. This level of control enables the creation of complex geometries, sharp edges, and fine features that are essential in many professional and industrial applications.

However, understanding the limitations is crucial. The use of resin as a material requires proper handling and ventilation due to its chemical properties. Additionally, the support structures needed for overhangs and undercuts can leave marks that require post-processing. Despite these considerations, the advantages of resin 3D printing in producing high-quality parts make it a valuable tool in various fields.

The benefits of using a resin 3D printer

One of the most significant advantages of resin 3D printers is their superior surface finish. Objects printed with resin exhibit smooth surfaces and a level of detail that is unparalleled by filament-based 3D printers. This makes resin printing particularly appealing for applications where aesthetic quality is paramount.

Another benefit is the speed of printing. Although dependent on the complexity and size of the print, resin printers can often complete jobs faster than their filament counterparts. This efficiency is due to the nature of the curing process, which can solidify entire layers simultaneously, rather than tracing each layer point by point.

Furthermore, the versatility of resin materials allows for a broad spectrum of applications. From rigid and durable to flexible and transparent, the range of available resins means that users can select the ideal material properties for their specific project needs. This adaptability opens up new possibilities in fields such as dental, jewelry, and prototype manufacturing.

Common applications of resin 3D printers

Resin 3D printers have found a niche in industries that value precision and detail above all. In the dental industry, for example, practitioners utilize resin printing for creating highly accurate dental models and custom appliances. The ability to produce these items in-house revolutionizes patient care by reducing wait times and improving customization.

In the realm of jewelry making, resin 3D printers enable designers to create intricate patterns and molds that were previously impossible or prohibitively expensive. This technology democratizes the design process, allowing for rapid prototyping and experimentation at a fraction of the cost of traditional methods.

Moreover, the educational sector benefits from resin 3D printers by providing students with access to high-quality models for study and research. Whether in biology, engineering, or art, the tactile experience of holding a detailed model enhances learning and creativity.

Key considerations before purchasing

Investing in a resin 3D printer requires careful consideration of several factors. Firstly, the initial cost and ongoing expenses for materials and maintenance can be significant. Prospective buyers should assess their budget and the potential return on investment that a resin printer could bring to their projects or business.

Secondly, the learning curve for operating a resin 3D printer and post-processing prints can be steep for beginners. While the technology is becoming more user-friendly, achieving optimal results often requires experimentation and experience.

Lastly, the safety and environmental aspects cannot be overlooked. Handling liquid resin and dealing with post-processing chemicals demand proper safety equipment and ventilation. Users should familiarize themselves with the best practices to ensure a safe and sustainable operation.

Maintenance and safety tips

Maintaining a resin 3D printer is essential for ensuring its longevity and performance. Regular cleaning of the resin vat, checking the UV light source, and updating the printer’s firmware are all crucial steps. Additionally, filtering and properly storing unused resin can prevent contamination and waste.

Safety is paramount when working with resin printers. Utilizing gloves, masks, and protective eyewear can minimize exposure to potentially harmful chemicals. Moreover, working in a well-ventilated area or using an air filtration system helps to maintain a healthy environment.

Conclusion

Resin 3D printers offer unparalleled precision, speed, and versatility, making them an invaluable tool across various industries. By understanding the technology, its applications, and the considerations involved, users can harness the full potential of resin printing. With the right approach to maintenance and safety, resin 3D printing can open new horizons in manufacturing, design, and education, pushing the boundaries of what’s possible.