The magnetic drill press is one of the valuable tools for the metalworking industry. It is designed with a magnet that helps the tool to hold the metal in one place for assured drilling without the slightest vibrations in the port. Due to its incredible accuracy, drilling metals, and its ability to work with power, it is one of the valuable tools for metalworking. This article gives an insight into what a magnetic drill press is, how it works, how to work with it, the cost and the best models.

Table of Contents:

1. What is a magnetic drill press?

2. How do magnetic drill presses work?

3. How to use a magnetic drill press

4. How much does a magnetic drill press cost?

5. Top magnetic drill presses

What is a magnetic drill press?

Magnetic drill presses (also known as ‘mag drills’) are heavy-duty portable drills used to bore small holes in metalwork. Magnetic drills differ from traditional drill presses, which are stationary machines where the material is brought to the machine. In contrast, a magnetic drill press can be clamped to the material being drilled, providing greater flexibility and usability.

In order to accomplish this, magnetic drill presses have a large electromagnet that can attach the base of the drill to a ferrous metal surface, providing stability and precision. This is useful in construction, manufacturing and maintenance work, where drilling operations have to be carried out on-site and in different orientations.

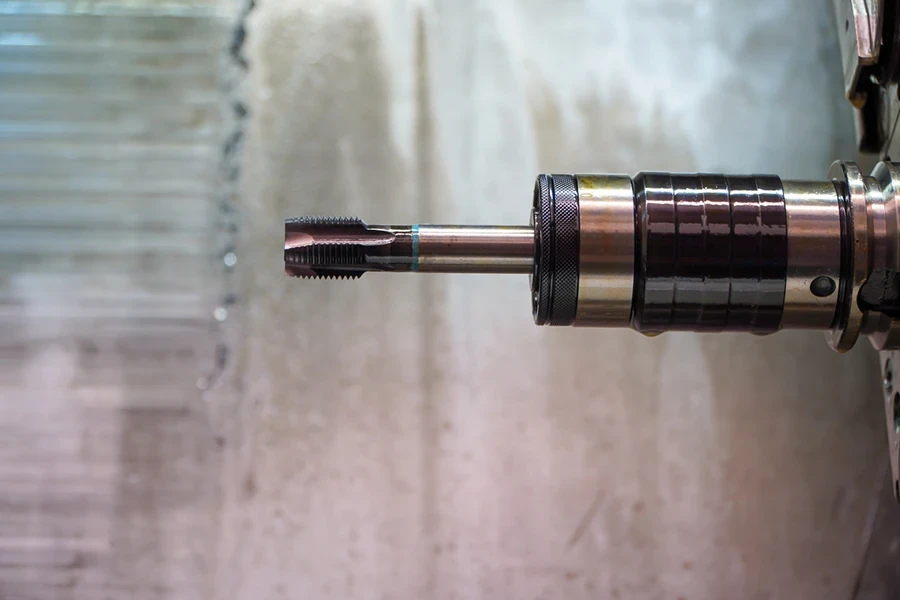

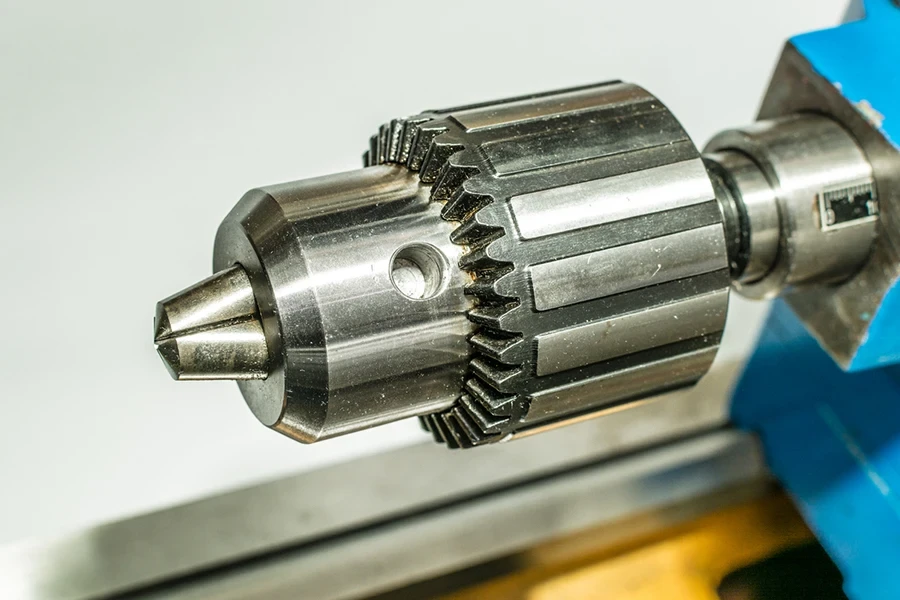

Magnetic drill press has several moving parts such as the magnetic base, the drill motor and the chuck or arbor. It can be equipped with different types of from twist drills to annular cutters to countersinks for various applications.

How do magnetic drill presses work?

The way it works is that the electromagnet that operates on a magnetic drill press is the first thing to go to work. When we turn on the magnet, it builds up magnetic flux around the base of the drill that holds it in place to the ferrous metal surface you’re working on. Given that the magnet is in that position, the chance of you making an imprecise or inaccurate hole are virtually nil – especially when you’re working in a vertical or overhead position.

After securing the drill press to the work piece, the operator selects the drill bit of the desired size, mounts it either into the chuck or into the arbour, and activates the motor, which can be either an electric motor or a battery powered motor. Depending on the makeup of the material being drilled and the size of the hole being drilled, the motor speed and torque can be modified.

Some models also feature additional accessories such as automatic lubrication systems, which reduce friction and heat during drilling operations, hence extending the life cycle of the drill bit and improving hole quality and finish. Other high-end models can further offer variable speed controls, reverse functions and digital displays of relevant operations metrics for improving the precision and ease of use when it comes to magnetic drill presses.

How to use a magnetic drill press

Follow these steps to use a magnetic drill press safely and accurately. Prepare the work area by first cleaning the surface where you will mount the drill press. Any debris or rust can keep the drill from sticking to the surface and keep you from making a perfect hole.

Once the magnetic base is secured to the workpiece, make sure the drill is perpendicular to the workpiece so that the holes aren’t drilled at an angle. Insert the correct drill bit for the job, and tighten the chuck or arbor to the correct torque. Then set the speed and torque parameters based on the material and size of the hole.

As with turning, when drilling, you should apply a steady pressure with your feed hand and let the bit do the work. Don’t push it through the work; if you do, the bit will become overheated and become damaged, as will your workpiece. You should also be ready to add cutting fluid to help keep the bit cool, especially if you have a deep hole to work on. The bit will become clogged with chips, so be ready to back it out so that it can be cleared.

Safety when using a magnetic drill press must always be considered. Wear your PPE (personal protective equipment) – safety glasses/goggles, gloves and hearing protection. Make sure the power cord to the drill is kept out of the way. Never turn on the machine while changing the drill, bit or spindle.

How much does a magnetic drill press cost?

The price for a magnetic drill press can vary widely, depending on the brand, features and build quality. A basic model without a lot of bells and whistles intended for light-duty applications could cost as little as $300 to $500. This may be sufficient for an occasional user or hobbyist.

Models aimed at more demanding work and more frequent use start at the mid-range, around the $800 to $1,500 price. These larger tools include more robust motors, sturdier construction, and features such as variable speed control and automatic lubrication.

Professional- and industrial-grade drilling presses with high-powered motors, advanced electronics and increased durability can cost between $2,000 and $5,000 or more.

The cost of ownership, however, will also depend upon the lifetime value and specific needs of your projects. A well-built and precise magnetic drill press can help boost productivity and minimise downtime.

Top magnetic drill presses

Many companies manufacture high-end magnetic drill presses. Each of them has its own distinctive features and advantages. Let’s view some the most famous models at the present time.

1. Hougen HMD904: The Most Powerful Lightweight Magnetic Drill – 1,450lbs Mag Force! The Hougen HMD904, the best-selling professional magnetic drill, is back in stock at MSC Industrial Supply! It features: • 1 450lbs magnetic adhesion force • two-speed gearbox 1/7 to 1/22 rpm • working range 12.75 inches • ergonomic handle shape for easy operation For more information about this machine, visit the MSC Industrial Supply website.

2. DEWALT DWE1622K: This is the all-rounder model from DEWALT. It has a powerful 10-amp motor and a quick-change chuck system for effortless bit changes, as well as a built-in coolant tank and overload protection.

3. Milwaukee 2787-22 M18: Brushless Cordless Impact Wrench With REDLRINK PLUS Intelligence and a powerful brushless motor, this Milwaukee 2787-22 M18 can handle tough jobsites and protect itself from damage. Its cordless design means you don’t have to worry about finding a power outlet.

4. Evolution Power Tools EVO28: This conveniently compact portable evacuated drill press has a 7-amp motor and 2,800 lbs of magnetic adhesion. Weighing less than 20lbs and priced under $300, this tool is an excellent alternative to a drill press.

5. Metabo MAG 50: This ultra high-performance model from Metabo has a 10.5-amp motor with variable speed control for a powerful cut, metal swivel base for a precise position, and heavy-duty construction with industrial use in mind.

Conclusion

For someone who works with metal, there is no substitute for a magnetic drill press. It can be used for precision drilling, power drilling, and almost anything in between, and packs a lot of power into a small package. In this article, we are going to examine how these machines work, what they are useful for, and how to determine the best price for the one you’re looking for. When you’re ready to upgrade your workshop or find a portable option for a construction site, you’ll have everything you need to know to choose the magnetic drill press that’s right for you.