Compressors play a pivotal role in the functionality and efficiency of various vehicle systems. From air conditioning units to turbochargers, understanding the intricacies of compressors can significantly impact your vehicle’s performance. This article aims to demystify compressors, offering insights into their types, functions, maintenance, common issues, and the latest technological advancements. Whether you’re a seasoned mechanic or a curious car owner, this guide will equip you with the knowledge to make informed decisions about your vehicle’s compressor needs.

Table of Contents:

– What are compressors and how do they work?

– Types of compressors in vehicles

– Maintenance tips for vehicle compressors

– Common issues with vehicle compressors

– Latest technological advancements in compressors

What are compressors and how do they work?

Compressors, in essence, are devices used to increase the pressure of a gas by reducing its volume. In vehicles, they are crucial for several systems, notably the air conditioning system and the engine’s turbocharging system. The principle behind their operation involves drawing in the ambient air, compressing it, and then delivering it at a higher pressure. This process not only aids in cooling but also enhances the engine’s power output by allowing more air, and consequently more fuel, to be burned.

The significance of compressors extends beyond comfort and performance. They also play a role in reducing vehicle emissions. By optimizing the air-fuel mixture in the engine, compressors contribute to more efficient combustion, leading to lower exhaust emissions.

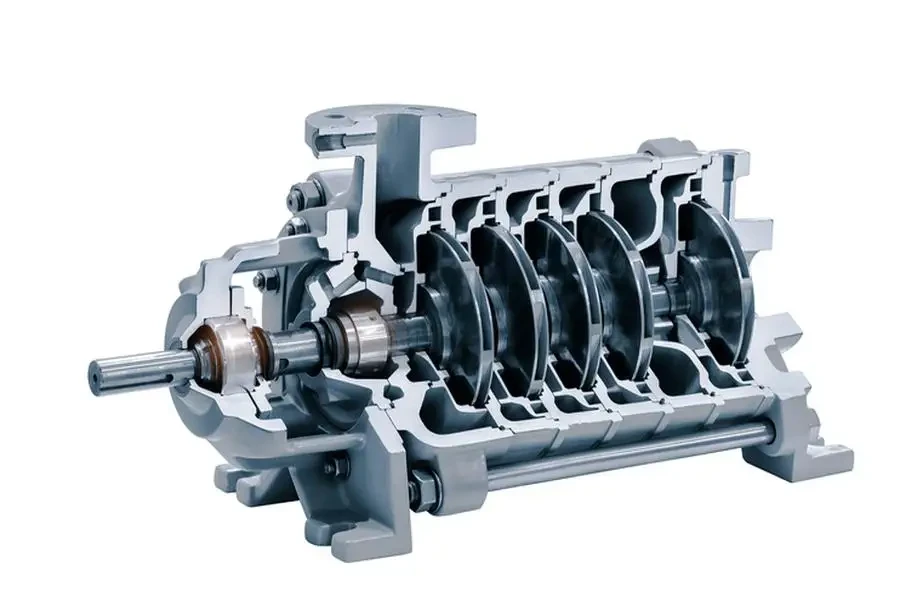

Understanding the mechanics of compressors involves recognizing their components, such as pistons, rotors, and valves, and how these parts work together to compress air. This knowledge is essential for diagnosing issues and performing maintenance, ensuring the longevity and reliability of the compressor and the systems it supports.

Types of compressors in vehicles

Vehicle compressors can be broadly categorized into two types: positive displacement compressors and dynamic compressors. Positive displacement compressors work by mechanically reducing the volume of air to increase its pressure. Common examples found in vehicles include piston compressors, used in air conditioning systems, and screw compressors, often used in larger vehicles for air brake systems.

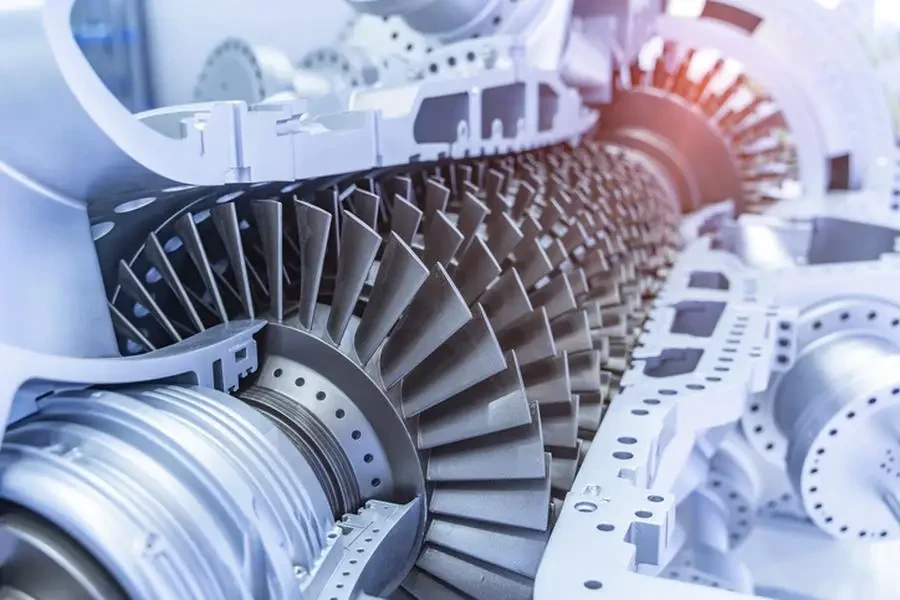

Dynamic compressors, on the other hand, use high-speed rotating blades to accelerate air, thereby increasing its pressure. Centrifugal compressors are a typical example, frequently used in turbochargers. They offer the advantage of being able to deliver a high flow of air, which is crucial for enhancing engine performance.

Each type of compressor has its unique benefits and applications, making it vital to choose the right one for your vehicle’s specific needs. Factors such as the intended use, required pressure, and flow rate, as well as energy efficiency, should be considered when selecting a compressor.

Maintenance tips for vehicle compressors

Regular maintenance is crucial for the longevity and efficient operation of vehicle compressors. Simple steps, such as regularly checking the compressor’s oil level and replacing it according to the manufacturer’s recommendations, can prevent many common issues. It’s also important to inspect the compressor’s belts and replace them if they show signs of wear or damage.

Keeping the compressor clean from dirt and debris is another key aspect of maintenance. This not only ensures efficient operation but also prevents overheating, which can lead to premature failure. In addition, ensuring that the compressor’s intake filters are clean and free from blockages will maximize airflow and performance.

Adhering to a regular maintenance schedule can significantly extend the life of your vehicle’s compressor, reduce the likelihood of breakdowns, and ensure optimal performance. It’s a small investment that can lead to significant savings in the long run.

Common issues with vehicle compressors

Despite regular maintenance, compressors can still encounter issues. Common problems include leaks, which can lead to reduced efficiency and performance, and compressor clutch failures, which can prevent the compressor from operating altogether. Noise is another indicator of potential issues, often signaling internal wear or damage.

Diagnosing compressor problems early is key to preventing more significant issues down the line. If you notice any signs of trouble, such as unusual noises, decreased performance, or higher than normal operating temperatures, it’s important to have your compressor checked by a professional.

Addressing compressor issues promptly not only ensures the continued performance and efficiency of your vehicle but also helps avoid more costly repairs in the future. It’s an essential aspect of vehicle care that should not be overlooked.

Latest technological advancements in compressors

The field of compressors is continually evolving, with new technologies aimed at increasing efficiency, reducing emissions, and enhancing performance. Variable speed compressors are one such advancement, allowing the compressor’s output to be precisely matched to the system’s needs, thereby reducing energy consumption.

Electric compressors are another area of innovation, particularly relevant in the context of electric and hybrid vehicles. These compressors are powered by the vehicle’s battery, offering a more efficient and environmentally friendly alternative to traditional belt-driven compressors.

Advancements in materials and design are also contributing to more durable and efficient compressors. For example, the use of lighter, stronger materials can reduce the compressor’s weight, contributing to overall vehicle efficiency.

Staying informed about the latest advancements in compressor technology can help you make better decisions about your vehicle’s maintenance and upgrades, ensuring optimal performance and efficiency.

Conclusion:

Compressors are a vital component of modern vehicles, contributing to both comfort and performance. Understanding their types, functions, and maintenance requirements is essential for any vehicle owner or mechanic. By staying informed about common issues and the latest technological advancements, you can ensure that your vehicle’s compressor operates efficiently and reliably for years to come.