The realm of 3D printing, a marvel of modern engineering, has revolutionized how we create, innovate, and think about manufacturing. From intricate prototypes to functional parts, 3D printers bring ideas to life with precision and efficiency. This article delves into the intricate workings, usage, cost considerations, and top choices of 3D printers, offering a comprehensive guide for enthusiasts and professionals alike.

Table of Contents:

– What is a 3D printer?

– How do 3D printers work?

– How to use a 3D printer

– How much does a 3D printer cost?

– Top 3D printers

What is a 3D printer?

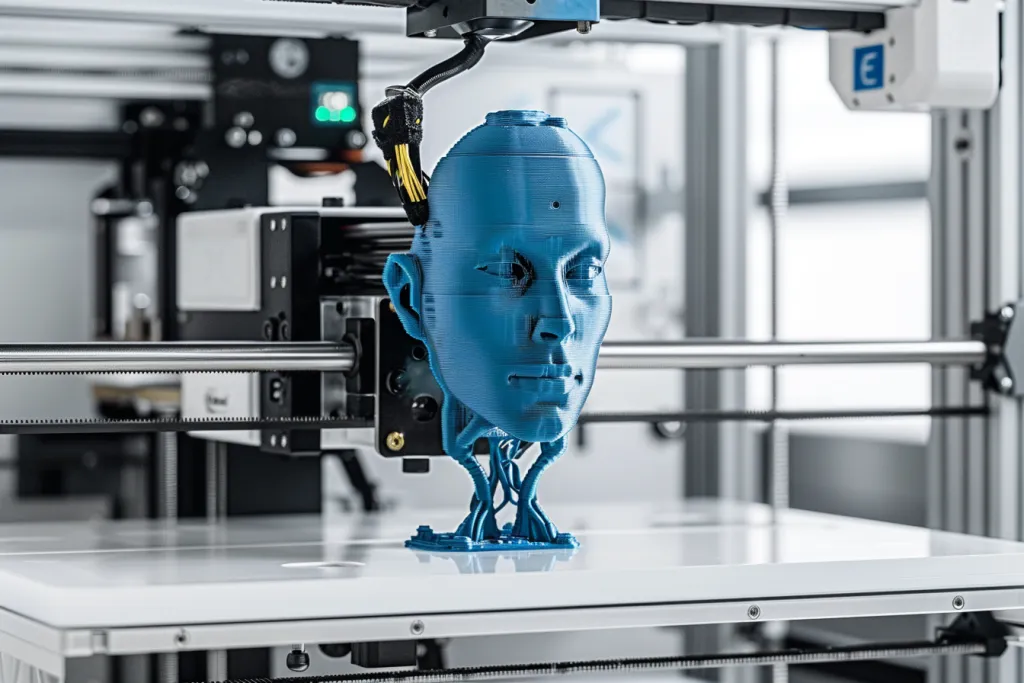

A 3D printer is a marvel of modern technology that transforms digital 3D models into solid, three-dimensional objects. It’s a type of additive manufacturing where a product is created by adding material layer by layer, which is quite the opposite of traditional subtractive manufacturing methodologies. This innovative approach allows for the creation of complex and detailed objects with a level of precision and customization that was unimaginable just a few decades ago.

The applications of 3D printing are vast and varied, ranging from prototyping and manufacturing in industries such as aerospace, automotive, and healthcare, to more personal uses like custom jewelry, home decor, and even fashion. The ability to quickly and affordably produce objects on demand has not only accelerated the design process but also opened up new avenues for creativity and experimentation.

How do 3D printers work?

The magic of 3D printing begins with a digital model, typically created using Computer-Aided Design (CAD) software. This model is then sliced into hundreds or thousands of horizontal layers using specialized slicing software. The 3D printer reads this sliced model as a blueprint and starts the printing process by laying down successive layers of material until the object is fully formed.

There are several technologies used in 3D printing, each with its own unique process and materials. The most common technology is Fused Deposition Modeling (FDM), where a thermoplastic filament is heated to its melting point and then extruded layer by layer to build the object. Stereolithography (SLA) and Digital Light Processing (DLP) are resin-based technologies that use ultraviolet (UV) light to cure liquid resin into solid plastic. Selective Laser Sintering (SLS), on the other hand, uses a laser to sinter powdered material, binding it together to create a solid structure.

How to use a 3D printer

Using a 3D printer starts with the creation or selection of a 3D model. This model can be designed from scratch using CAD software or downloaded from various online repositories. Once the model is ready, it’s processed through slicing software to convert it into a format that the 3D printer can understand, usually in the form of G-code.

The next step involves preparing the 3D printer, which includes loading the material (filament, resin, or powder), calibrating the print bed, and ensuring that all settings are optimized for the specific model and material. Once everything is set up, the printing process can begin. Depending on the size and complexity of the object, printing can take anywhere from a few hours to several days. After the print is completed, some post-processing, such as cleaning and removing support structures, may be required to achieve the final finish.

How much does a 3D printer cost?

The cost of 3D printers has significantly decreased over the years, making this technology more accessible to hobbyists, educators, and small businesses. Entry-level FDM printers can be found for as little as $200, making them a popular choice for beginners. Mid-range models, offering better resolution and larger build volumes, can range from $1,000 to $3,000. Professional-grade 3D printers, which provide high precision, advanced materials, and larger print capacities, can start at $5,000 and go up to $100,000 or more for industrial models.

The cost of materials also varies depending on the type and quality. Standard PLA and ABS filaments for FDM printers are relatively inexpensive, while specialized materials like flexible filaments, composite filaments, and high-quality resins for SLA/DLP printers can be more costly. Additionally, operating costs, including electricity, maintenance, and replacement parts, should also be considered when calculating the total cost of ownership.

Top 3D printers

The market for 3D printers is vast and varied, catering to different needs, preferences, and budgets. For beginners, the Creality Ender 3 V2 offers great value, combining ease of use with impressive print quality. The Prusa i3 MK3S+ stands out in the mid-range category, renowned for its reliability, precision, and open-source design. For professionals and businesses requiring high-resolution prints and versatility in materials, the Formlabs Form 3 is a top contender in the resin printer category, while the Ultimaker S3 offers exceptional performance and material compatibility in the FDM segment.

Choosing the right 3D printer depends on several factors, including the intended use, desired print quality, material requirements, and budget. It’s crucial to research and compare different models to find the one that best suits your specific needs.

Conclusion: 3D printers are transformative tools that have democratized manufacturing, enabling both individuals and industries to bring their ideas to life with unprecedented speed and flexibility. Whether you’re a hobbyist looking to explore creative projects or a professional seeking to prototype and innovate, there’s a 3D printer out there for you. With the right knowledge and resources, navigating the world of 3D printing can be a rewarding and exciting journey.