CO2 laser engravers have revolutionized the way we approach cutting and engraving materials, offering unparalleled precision and versatility. From intricate designs on wood and acrylic to detailed markings on glass and leather, these machines cater to a wide array of applications. This article delves into the intricacies of CO2 laser engravers, guiding you through their operation, usage, and the top models available.

Table of Contents:

– What is a CO2 laser engraver?

– How does a CO2 laser engraver work?

– How to use a CO2 laser engraver

– How much does a CO2 laser engraver cost?

– Top CO2 laser engravers

What is a CO2 laser engraver?

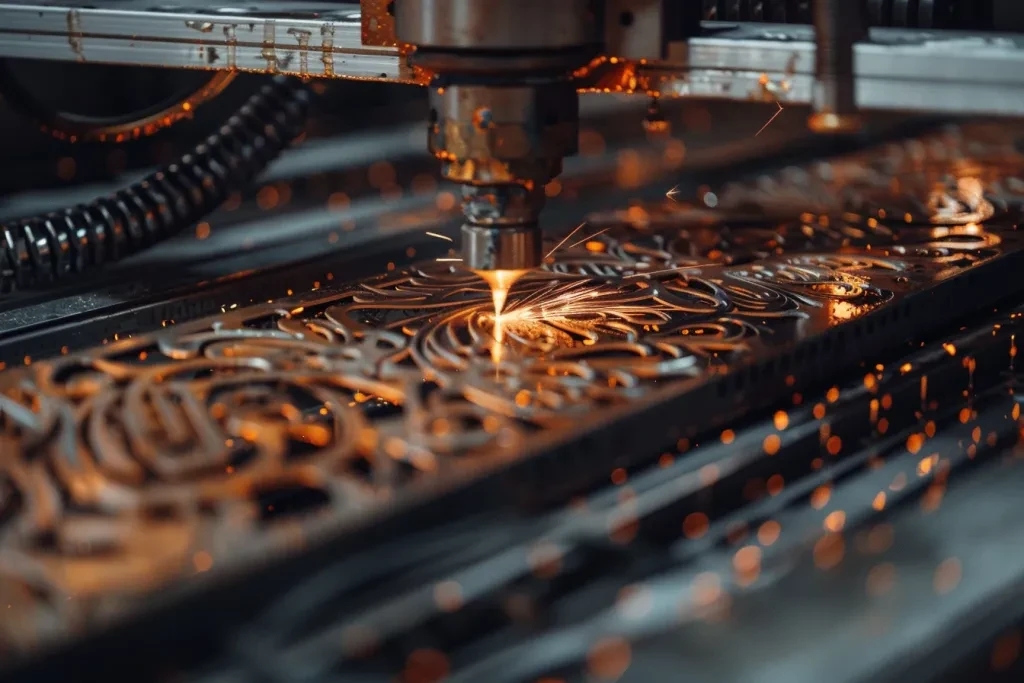

A CO2 laser engraver is a sophisticated piece of machinery designed for cutting, marking, and engraving various materials with exceptional precision. It operates using a carbon dioxide gas mixture, which is electrically stimulated to produce a laser beam. This technology is favored for its versatility, allowing for detailed work on materials such as wood, acrylic, glass, leather, and even some metals. The precision and speed of a CO2 laser engraver make it an indispensable tool in industries ranging from manufacturing and engineering to design and artistry.

How does a CO2 laser engraver work?

The core of a CO2 laser engraver’s functionality lies in its laser tube, which contains a mixture of carbon dioxide gas, nitrogen, hydrogen, and helium. When electricity is applied, the gas mixture is excited, producing a powerful and concentrated beam of light. This laser beam is then directed towards the material to be cut or engraved, precisely vaporizing or melting it along the desired path. The machine’s system controls the movement of the laser beam, allowing for intricate designs and precise cuts. The efficiency and quality of the engraving or cutting process are significantly influenced by the machine’s power, speed settings, and the type of lens used to focus the laser beam.

How to use a CO2 laser engraver

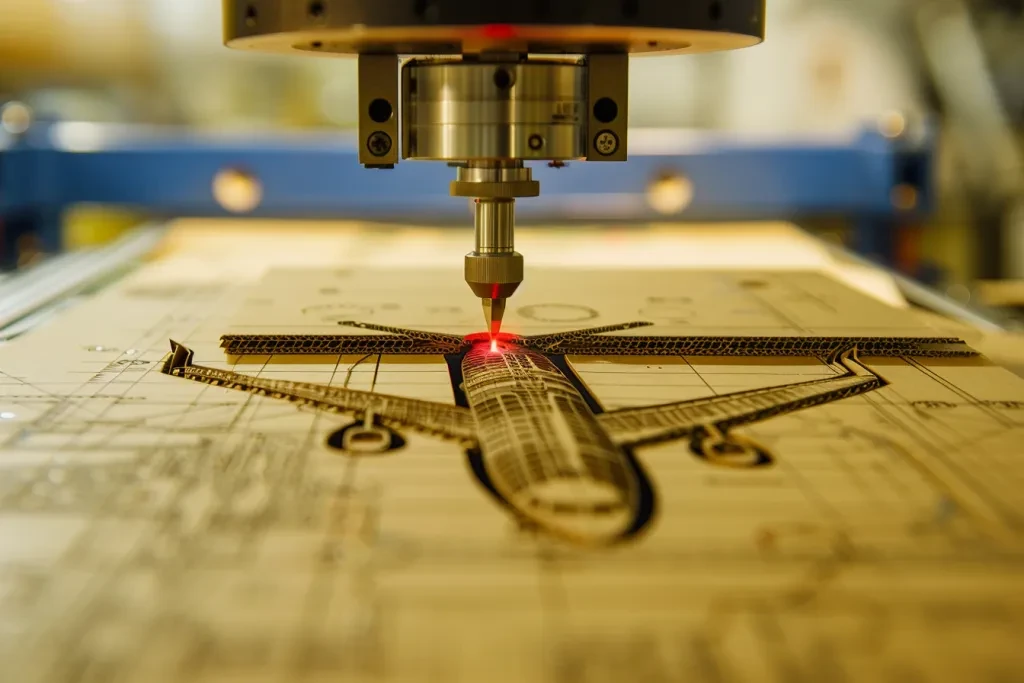

Using a CO2 laser engraver involves several key steps, starting with the preparation of the design to be engraved or cut. This design is usually created or imported into specialized software compatible with the laser engraver. Once the design is ready, material selection and placement are crucial, as different materials require different laser settings for optimal results. The user then adjusts the machine’s settings, such as power, speed, and focus, according to the material and the desired outcome. After ensuring all safety measures are in place, the operator initiates the engraving or cutting process. Post-processing may include cleaning and applying finishing touches to the engraved or cut piece.

How much does a CO2 laser engraver cost?

The cost of a CO2 laser engraver can vary widely depending on its size, power, and feature set. Entry-level models suitable for hobbyists and small businesses can start around $500, offering basic functionality for light engraving tasks. Mid-range models, which provide greater power and versatility for more demanding applications, can range from $2,000 to $8,000. For industrial-grade machines designed for high volume and precision work, prices can soar upwards of $20,000. When considering the cost, potential buyers should also factor in maintenance expenses, replacement parts, and the cost of consumables like the laser tube and focusing lens.

Top CO2 laser engravers

When it comes to selecting a CO2 laser engraver, the market is filled with numerous options catering to different needs and budgets. Among the top contenders, models from brands like Epilog Laser, Universal Laser Systems, and Trotec stand out for their reliability, efficiency, and cutting-edge features. These machines offer a range of powers, bed sizes, and advanced functionalities, such as integrated cameras for material alignment and intuitive software interfaces. For hobbyists and small businesses, Glowforge and K40 laser cutters provide cost-effective solutions without significantly compromising on performance. Each of these models excels in different aspects, making it essential to consider your specific requirements when choosing the best CO2 laser engraver for your needs.

Conclusion:

CO2 laser engravers offer a dynamic and precise tool for cutting, marking, and engraving a wide range of materials. Understanding how these machines work, how to use them effectively, and what options are available in terms of cost and features can help users unlock their full potential. Whether for professional manufacturing, creative design, or personal projects, a CO2 laser engraver can be a game-changing addition to your toolkit.