In 2025, the demand for high-precision machining tools is set to rise, driven by advancements in manufacturing technologies. This article delves into the essential features, benefits, and types of drill press vises, providing professional buyers with valuable insights to make informed purchasing decisions. By understanding these aspects, businesses can enhance their operational efficiency and product quality.

Table of Contents:

– Understanding Drill Press Vises and Their Importance

– Types of Drill Press Vises for Different Applications

– Factors to Consider When Choosing a Drill Press Vise

– Comparing Leading Brands in the Drill Press Vise Market

– Latest Trends in Drill Press Vise Technology

– Practical Tips for Maintaining Your Drill Press Vise

– Conclusion

Understanding Drill Press Vises and Their Importance

Key Features of Drill Press Vises

Drill press vises are essential tools in machining, providing stability and precision during drilling operations. Key features include robust construction, typically from cast iron or steel, ensuring durability and resistance to wear. The vises often incorporate hardened steel jaws, which enhance grip and reduce the risk of workpiece slippage. Additionally, many models feature a quick-release mechanism, allowing for rapid adjustments and increased efficiency during repetitive tasks.

Another critical feature is the precision-ground base, which ensures accurate alignment with the drill press table. This alignment is crucial for maintaining the perpendicularity of the drill bit to the workpiece, thereby enhancing the accuracy of drilled holes. Some advanced vises also include a swivel base, offering rotational flexibility and enabling angled drilling without repositioning the workpiece. This feature is particularly beneficial in complex machining operations where multiple angles are required.

Furthermore, drill press vises often come with adjustable gibs, which allow for fine-tuning of the vise’s movement. This adjustment helps in maintaining smooth operation and reducing play, which is vital for achieving high precision in drilling tasks. The inclusion of T-slots in the base also facilitates secure mounting to the drill press table, ensuring stability during operation. These features collectively contribute to the vise’s ability to handle a wide range of drilling applications with high precision and reliability.

Benefits of Using Drill Press Vises

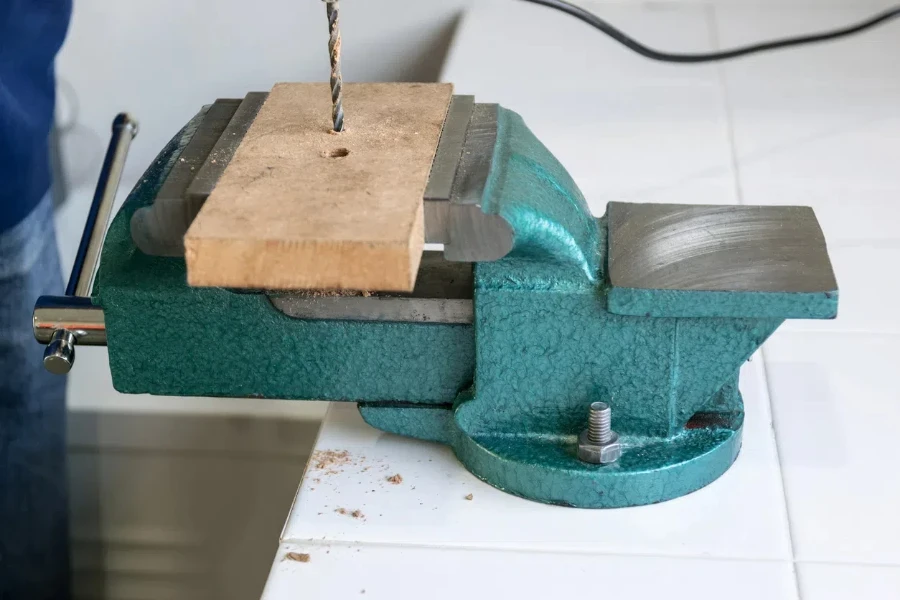

The use of drill press vises offers numerous benefits, primarily enhancing the accuracy and safety of drilling operations. By securely holding the workpiece, the vise minimizes movement and vibration, leading to more precise hole placement. This stability is particularly important in high-precision applications, such as in the aerospace and automotive industries, where even minor deviations can result in significant issues.

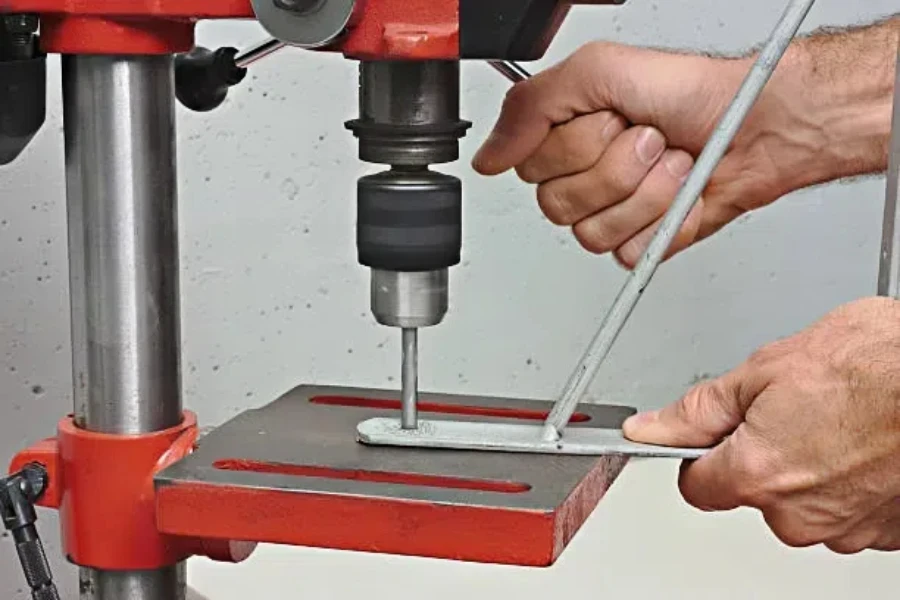

Another significant benefit is the increased safety provided by drill press vises. By firmly clamping the workpiece, the risk of it being ejected or shifting during drilling is greatly reduced. This not only protects the operator from potential injuries but also prevents damage to the workpiece and the drill bit. Additionally, the use of a vise allows for hands-free operation, enabling the operator to focus on controlling the drill press and ensuring optimal drilling conditions.

Moreover, drill press vises contribute to improved efficiency in machining operations. The quick-release mechanism and adjustable features allow for rapid setup and adjustments, reducing downtime between tasks. This efficiency is further enhanced by the vise’s ability to handle various workpiece sizes and shapes, making it a versatile tool in any machining environment. The combination of precision, safety, and efficiency makes drill press vises an indispensable component in modern manufacturing processes.

Types of Drill Press Vises for Different Applications

Standard Drill Press Vises

Standard drill press vises are the most commonly used type, designed for general-purpose drilling tasks. These vises typically feature a simple, robust design with a fixed base and adjustable jaws. The jaws are often serrated to provide a firm grip on the workpiece, preventing slippage during drilling. Standard vises are suitable for a wide range of materials, including metals, plastics, and wood, making them versatile tools in various machining environments.

The construction of standard drill press vises usually involves high-quality cast iron or steel, ensuring durability and long service life. The base of the vise is precision-ground to ensure accurate alignment with the drill press table, which is crucial for maintaining drilling accuracy. Additionally, many standard vises come with a quick-release mechanism, allowing for rapid adjustments and increased efficiency during repetitive tasks. This feature is particularly beneficial in production settings where time is a critical factor.

Standard drill press vises are available in various sizes, with jaw widths typically ranging from 2 inches to 6 inches. The choice of size depends on the specific requirements of the drilling task, including the size and shape of the workpiece. These vises are ideal for applications that do not require complex positioning or angling, providing a reliable and straightforward solution for everyday drilling needs.

Angle Drill Press Vises

Angle drill press vises are designed to facilitate drilling at various angles, offering greater flexibility compared to standard vises. These vises feature a tilting mechanism that allows the workpiece to be positioned at precise angles, typically ranging from 0 to 90 degrees. This capability is particularly useful in applications where angled holes are required, such as in the fabrication of brackets, frames, and other components with complex geometries.

The construction of angle drill press vises is similar to that of standard vises, with robust materials like cast iron or steel ensuring durability and stability. However, the addition of the tilting mechanism introduces additional complexity, requiring precise engineering to maintain accuracy. The tilting base is often equipped with a protractor scale, allowing the operator to set the desired angle with high precision. This feature is essential for achieving consistent results in angled drilling operations.

Angle drill press vises are available in various sizes and configurations, with some models offering both tilting and swiveling capabilities. This combination provides even greater flexibility, enabling the workpiece to be positioned at virtually any angle. These vises are ideal for applications in industries such as aerospace, automotive, and metalworking, where complex drilling tasks are common. The ability to drill at precise angles without repositioning the workpiece significantly enhances efficiency and accuracy in these demanding environments.

Cross-Slide Drill Press Vises

Cross-slide drill press vises are designed for precision drilling tasks that require fine adjustments in both the X and Y axes. These vises feature a dual-axis mechanism that allows the workpiece to be moved horizontally and vertically with high precision. This capability is particularly useful in applications where multiple holes need to be drilled in a precise pattern, such as in the production of circuit boards, metal plates, and other components with intricate designs.

The construction of cross-slide drill press vises involves high-quality materials like cast iron or steel, ensuring durability and stability. The dual-axis mechanism is typically equipped with lead screws and handwheels, allowing for smooth and precise adjustments. The base of the vise is precision-ground to ensure accurate alignment with the drill press table, which is crucial for maintaining drilling accuracy. Additionally, many cross-slide vises come with adjustable gibs, allowing for fine-tuning of the vise’s movement to reduce play and ensure smooth operation.

Cross-slide drill press vises are available in various sizes, with jaw widths typically ranging from 3 inches to 6 inches. The choice of size depends on the specific requirements of the drilling task, including the size and shape of the workpiece. These vises are ideal for applications that require high precision and repeatability, such as in the aerospace, automotive, and electronics industries. The ability to make fine adjustments in both the X and Y axes significantly enhances the accuracy and efficiency of drilling operations in these demanding environments.

Specialty Drill Press Vises

Specialty drill press vises are designed for specific applications that require unique features and capabilities. These vises often incorporate specialized jaws, bases, and clamping mechanisms to accommodate particular workpieces and drilling tasks. Examples of specialty vises include pipe vises, which are designed to hold cylindrical workpieces securely, and low-profile vises, which are ideal for drilling operations with limited vertical clearance.

The construction of specialty drill press vises varies depending on the specific application, but they generally involve high-quality materials like cast iron or steel to ensure durability and stability. The specialized jaws and clamping mechanisms are engineered to provide a secure grip on the workpiece, preventing slippage and ensuring accurate drilling. Some specialty vises also feature quick-release mechanisms and adjustable gibs, allowing for rapid adjustments and fine-tuning of the vise’s movement.

Specialty drill press vises are available in various sizes and configurations, with each type designed to meet the unique requirements of specific applications. These vises are ideal for industries such as plumbing, metalworking, and woodworking, where specialized drilling tasks are common. The ability to securely hold unique workpieces and accommodate specific drilling requirements significantly enhances the efficiency and accuracy of these operations, making specialty vises an essential tool in many machining environments.

Factors to Consider When Choosing a Drill Press Vise

Material and Build Quality

The material and build quality of a drill press vise are critical factors that determine its durability and performance. High-quality vises are typically constructed from cast iron or steel, which provide excellent strength and resistance to wear. Cast iron is known for its vibration-damping properties, making it an ideal material for reducing chatter during drilling operations. Steel, on the other hand, offers superior tensile strength and toughness, ensuring the vise can withstand heavy use and high clamping forces.

In addition to the base material, the quality of the jaws and other components is also important. Hardened steel jaws are preferred for their ability to maintain a firm grip on the workpiece and resist deformation over time. The precision-ground base and components ensure accurate alignment and smooth operation, which are essential for achieving high precision in drilling tasks. The overall build quality, including the fit and finish of the components, should be carefully evaluated to ensure the vise can provide reliable performance in demanding machining environments.

When choosing a drill press vise, it is also important to consider the manufacturer’s reputation and the availability of replacement parts. Reputable manufacturers are more likely to produce high-quality vises that meet industry standards and provide reliable performance. Additionally, the availability of replacement parts ensures that the vise can be maintained and repaired as needed, extending its service life and reducing downtime. By considering the material and build quality, buyers can select a drill press vise that offers durability, precision, and long-term value.

Jaw Width and Opening Capacity

The jaw width and opening capacity of a drill press vise are important factors that determine its suitability for different workpieces. Jaw width refers to the horizontal distance between the jaws when fully closed, while opening capacity refers to the maximum distance between the jaws when fully open. These dimensions dictate the size of the workpiece that the vise can securely hold, making them critical considerations for selecting the right vise for specific applications.

Standard drill press vises typically have jaw widths ranging from 2 inches to 6 inches, with larger vises offering greater versatility for handling a wider range of workpiece sizes. The opening capacity should be sufficient to accommodate the largest workpiece that will be used in the drilling operations. For example, a vise with a 4-inch jaw width and a 4-inch opening capacity can securely hold workpieces up to 4 inches in width and thickness. It is important to choose a vise with an appropriate jaw width and opening capacity to ensure it can handle the intended workpieces without compromising stability and precision.

In addition to the jaw width and opening capacity, the design of the jaws also plays a role in the vise’s performance. Serrated jaws provide a firm grip on the workpiece, preventing slippage during drilling. Some vises also feature replaceable jaws, allowing for customization and replacement as needed. By carefully considering the jaw width, opening capacity, and jaw design, buyers can select a drill press vise that meets their specific requirements and provides reliable performance in various drilling applications.

Clamping Force

Clamping force is a critical factor to consider when choosing a drill press vise, as it determines the vise’s ability to securely hold the workpiece during drilling operations. The clamping force is generated by the vise’s screw mechanism, which tightens the jaws around the workpiece. A higher clamping force ensures that the workpiece remains stable and does not shift or vibrate during drilling, which is essential for achieving accurate and precise holes.

The clamping force required for a specific application depends on the material and size of the workpiece, as well as the drilling conditions. For example, harder materials like metals require higher clamping forces to prevent movement, while softer materials like wood may require less force. It is important to choose a vise with a clamping force that matches the requirements of the intended drilling tasks. Some vises are equipped with a force indicator, allowing the operator to monitor and adjust the clamping force as needed.

In addition to the maximum clamping force, the design of the screw mechanism also affects the vise’s performance. A well-designed screw mechanism with smooth threads and a robust handle allows for easy and precise adjustments of the clamping force. Some vises also feature a quick-release mechanism, enabling rapid adjustments and reducing setup time. By considering the clamping force and the design of the screw mechanism, buyers can select a drill press vise that provides the necessary stability and precision for their drilling operations.

Precision and Accuracy

Precision and accuracy are paramount when selecting a drill press vise, as they directly impact the quality of the drilled holes. A vise with high precision ensures that the workpiece is held securely and aligned accurately with the drill bit, minimizing deviations and ensuring consistent results. Precision-ground components, such as the base and jaws, contribute to the overall accuracy of the vise, providing a stable and reliable platform for drilling operations.

One of the key features that enhance precision and accuracy is the adjustable gib. The gib is a tapered strip that can be adjusted to eliminate play and ensure smooth movement of the vise’s components. By fine-tuning the gib, the operator can achieve precise control over the vise’s movement, which is essential for maintaining alignment and achieving accurate drilling results. Some vises also feature a protractor scale or angle gauge, allowing for precise setting of angles in angled drilling operations.

Another important aspect of precision and accuracy is the alignment of the vise with the drill press table. A precision-ground base ensures that the vise sits flat and level on the table, maintaining the perpendicularity of the drill bit to the workpiece. Additionally, the use of T-slots and mounting hardware allows for secure attachment of the vise to the table, preventing movement during drilling. By considering the precision and accuracy features of a drill press vise, buyers can select a tool that provides reliable performance and high-quality results in their drilling operations.

Comparing Leading Brands in the Drill Press Vise Market

Wilton

Wilton is renowned for its high-quality drill press vises, which are designed to provide precision and durability. Their vises are constructed from heavy-duty cast iron, ensuring long-lasting performance even under rigorous use. Wilton’s vises feature precision-machined jaws that offer a secure grip on workpieces, minimizing slippage during drilling operations.

One of the standout features of Wilton drill press vises is their quick-release mechanism. This allows for rapid adjustments, enhancing workflow efficiency in busy workshops. Additionally, Wilton vises often come with a swivel base, providing versatility in positioning the workpiece at various angles for complex drilling tasks.

Wilton’s commitment to quality is evident in their adherence to strict manufacturing standards. Their vises are subjected to rigorous testing to ensure they meet industry benchmarks for accuracy and reliability. This makes Wilton a preferred choice for professionals seeking dependable and precise drill press vises.

Palmgren

Palmgren offers a range of drill press vises that are highly regarded for their robust construction and precision. Their vises are made from high-grade materials, including cast iron and steel, which provide excellent durability and stability. Palmgren vises are designed to withstand heavy-duty use, making them suitable for industrial applications.

A key feature of Palmgren drill press vises is their precision-ground jaws. These jaws ensure a tight grip on the workpiece, reducing the risk of movement during drilling. Palmgren vises also come with adjustable gibs, which allow for fine-tuning of the vise’s alignment, ensuring optimal accuracy in drilling operations.

Palmgren’s vises are known for their versatility, with many models featuring a 360-degree swivel base. This allows users to position the workpiece at any angle, facilitating complex drilling tasks. Additionally, Palmgren vises are equipped with a quick-release mechanism, enabling fast and easy adjustments, which is particularly beneficial in high-volume production environments.

Yost

Yost is a well-established brand in the drill press vise market, known for its innovative designs and high-quality products. Yost vises are constructed from durable materials such as cast iron and steel, ensuring they can withstand the demands of heavy-duty drilling applications. Their vises are designed to provide a secure and stable grip on workpieces, enhancing precision and safety.

One of the notable features of Yost drill press vises is their multi-jaw design. This allows for a more versatile grip on various shapes and sizes of workpieces, making Yost vises suitable for a wide range of drilling tasks. Additionally, Yost vises often come with a swivel base, providing flexibility in positioning the workpiece.

Yost is committed to innovation, and their vises often incorporate advanced features such as quick-release mechanisms and adjustable gibs. These features enhance the usability and accuracy of the vises, making them a popular choice among professionals. Yost’s focus on quality and innovation ensures their vises meet the highest standards of performance and reliability.

Latest Trends in Drill Press Vise Technology

Automation and Smart Features

The integration of automation and smart features in drill press vises is a significant trend in the industry. Automated vises can be programmed to adjust their grip and positioning based on the specific requirements of the drilling task. This reduces the need for manual adjustments, increasing efficiency and precision in drilling operations.

Smart vises are equipped with sensors that monitor various parameters such as clamping force and workpiece alignment. These sensors provide real-time feedback to the operator, ensuring optimal performance and reducing the risk of errors. Additionally, smart vises can be integrated with CNC machines, allowing for seamless coordination between the vise and the drilling equipment.

The adoption of automation and smart features in drill press vises is driven by the need for increased productivity and accuracy in manufacturing processes. These advanced vises enable operators to perform complex drilling tasks with greater ease and precision, reducing downtime and improving overall efficiency. As technology continues to evolve, the use of automated and smart vises is expected to become more widespread in the industry.

Ergonomic Design Improvements

Ergonomic design improvements are another important trend in the drill press vise market. Manufacturers are focusing on creating vises that are not only functional but also comfortable to use. Ergonomically designed vises reduce operator fatigue and the risk of repetitive strain injuries, enhancing overall productivity and safety in the workplace.

One of the key ergonomic features being incorporated into drill press vises is the use of soft-grip handles. These handles provide a comfortable and secure grip, reducing the effort required to operate the vise. Additionally, vises with adjustable height and angle settings allow operators to position the workpiece at a comfortable working height, minimizing strain on the back and shoulders.

Another ergonomic improvement is the inclusion of quick-release mechanisms that allow for easy and fast adjustments. This reduces the time and effort required to change the position of the workpiece, enhancing workflow efficiency. As the importance of workplace ergonomics continues to be recognized, the demand for ergonomically designed drill press vises is expected to grow.

Practical Tips for Maintaining Your Drill Press Vise

Regular maintenance of your drill press vise is essential to ensure its longevity and optimal performance. One of the most important maintenance tasks is to keep the vise clean and free from debris. After each use, wipe down the vise with a clean cloth to remove any metal shavings, dust, or other contaminants that may have accumulated.

Lubrication is another crucial aspect of drill press vise maintenance. Apply a light coat of machine oil to the moving parts of the vise, such as the screw and the sliding surfaces. This will help to reduce friction and prevent rust, ensuring smooth operation and extending the life of the vise. Be sure to use a lubricant that is compatible with the materials of your vise.

Inspecting the vise regularly for signs of wear and damage is also important. Check the jaws for any signs of wear or deformation, and replace them if necessary. Additionally, inspect the screw and other moving parts for any signs of damage or excessive wear. If any parts are damaged, replace them promptly to prevent further damage and ensure the vise continues to operate effectively.

Conclusion:

In conclusion, maintaining your drill press vise through regular cleaning, lubrication, and inspection is essential for ensuring its longevity and optimal performance. By following these practical tips, you can keep your vise in excellent condition and enhance the efficiency and accuracy of your drilling operations.