In 2024, the global automatic heat press machine market surged to a value of US$1.19 billion, reflecting a rising demand for efficient heat application solutions. As we move into 2025, the trend towards digitalization and eco-friendly technologies is expected to continue shaping the industry. For business buyers, understanding the nuances of selecting the right machine is crucial for capitalizing on this growth and meeting diverse market needs.

Table of Contents:

– Current Landscape and Future Prospects

– Key Factors When Selecting an Automatic Heat Press Machine

– Importance of Safety Standards and Certifications

– Enhancing Efficiency with Advanced Technology

– Practical Examples of Advanced Features

– Conclusion

Current Landscape and Future Prospects

Market Overview: A Growing Demand for Efficiency

The automatic heat press machine market is experiencing notable growth due to the rising demand for efficient and precise heat application solutions. By 2024, the global market for these machines is expected to reach approximately US$1.19 billion. It is projected to grow at a compound annual growth rate (CAGR) of 3.89% from 2024 to 2029, reaching a market volume of US$1.44 billion by 2029. The United States is set to lead with an anticipated revenue of US$52.07 million in 2024, indicating strong demand for advanced heat press technologies.

The surge in digital technologies and automation in manufacturing is a key driver of market growth. User penetration in the heat press machine market is expected to rise from 4.7% in 2024 to 5.9% by 2029. The average revenue per user (ARPU) is projected at US$0.36k, reflecting increased consumer investment in high-performance heat press equipment. Additionally, there is a growing trend towards eco-friendly and energy-efficient machines, aligning with global sustainability objectives.

China’s market is set for significant growth, with projected revenue of US$480.90 million in 2024, highlighting its leadership in the Asian market. Market dynamics are influenced by local regulatory standards and consumer preferences for innovative heat press solutions. The focus on reducing operational costs and boosting productivity is driving demand for automatic heat press machines across industries such as textiles, automotive, and electronics.

In-Depth Analysis: Key Factors Shaping the Market

Technological innovation defines the automatic heat press machine market, with manufacturers emphasizing product differentiation to stay competitive. Recent advancements include smart technologies and IoT integration, enabling remote monitoring and control of heat press operations. This digitalization enhances the efficiency and precision of heat application processes, meeting the evolving needs of industrial users.

Consumer preferences are shifting towards machines that offer convenience and energy efficiency, with increased demand for quick and consistent heat application. Seasonal demand peaks, particularly before the holiday season, coincide with intensified production activities. There is a notable shift towards online distribution channels, providing broader access to diverse product lines.

Environmental regulations significantly influence market strategies, as companies develop machines that meet stringent energy efficiency standards. Customer concerns, such as high energy consumption and limited machine versatility, are being addressed through innovative designs and enhanced functionalities. Brand strategies increasingly focus on sustainability, with manufacturers emphasizing their commitment to environmental stewardship as a key market differentiator.

Strategic Insights for Stakeholders

As the automatic heat press machine market evolves, stakeholders must adapt to emerging trends and consumer preferences to remain competitive. Integrating digital technologies and emphasizing sustainability are crucial for successful market strategies. Companies should invest in research and development to innovate and enhance product offerings, addressing the diverse needs of industrial users across various sectors.

Niche markets, such as textiles and automotive, offer significant growth opportunities for manufacturers specializing in automatic heat press machines. By focusing on eco-friendly and energy-efficient solutions, companies can strengthen their market position and drive long-term growth. As the market advances towards digitalization, leveraging IoT capabilities and smart technologies will be vital for optimizing operational efficiency and delivering superior customer value.

Key Factors When Selecting an Automatic Heat Press Machine

When choosing an automatic heat press machine, several critical factors must be considered to ensure it meets your business needs. Below, we explore these factors in detail.

Types of Automatic Heat Press Machines

Automatic heat press machines come in various types, each suited for different applications. Understanding these types is essential for making an informed decision.

Clamshell Heat Press Machines: These machines have a top platen that opens like a clamshell, making them compact and easy to use. They are ideal for small spaces and basic heat transfer tasks. Their simple design is user-friendly, though they may not work well with thicker materials due to limited opening angles.

Swing-Away Heat Press Machines: In these machines, the top platen swings away from the bottom platen, providing a full view and access to the work area. This design is beneficial for applying heat transfers to thicker materials and ensures even pressure distribution. However, they require more space due to the swinging motion.

Draw Heat Press Machines: These machines feature a bottom platen that pulls out like a drawer, allowing easy placement of materials. They are user-friendly and provide better visibility of the work area, reducing the risk of burns. The draw mechanism adds convenience, especially for high-volume production.

Hydraulic Heat Press Machines: These heavy-duty machines use hydraulic pressure for heat transfer. They are suitable for large-scale production and can handle thicker materials with ease. The hydraulic mechanism ensures consistent pressure, making them ideal for professional use.

Performance and Functionality

The performance and functionality of an automatic heat press machine are crucial for achieving high-quality results. Key aspects to consider include:

Temperature Range and Consistency: The machine should offer a wide temperature range to handle various materials and applications. Consistent temperature control is vital to avoid issues like scorching or incomplete transfers. Look for machines with digital temperature controls for precise settings.

Pressure Adjustability: Adjustable pressure settings allow you to tailor the pressure to different materials and thicknesses. Uniform pressure distribution is essential for achieving even transfers. Machines with easy-to-use pressure adjustment mechanisms are preferred.

Automation Features: Automatic heat press machines come with various automation features such as auto-open, auto-swing, and programmable settings. These features enhance efficiency and reduce manual intervention, making the process more streamlined, especially in high-volume production environments.

Build Quality and Durability

The build quality and durability of a heat press machine determine its longevity and reliability. Investing in a robust machine ensures consistent performance over time.

Frame and Platen Materials: High-quality materials such as steel frames and aluminum or Teflon-coated platens enhance durability and heat distribution. Avoid machines with plastic components, as they may not withstand high temperatures and prolonged use.

Warranty and Certifications: Check for manufacturer warranties and certifications that attest to the machine’s quality and safety standards. Certifications like CE and UL ensure that the machine meets industry safety regulations.

Maintenance Requirements: Consider the ease of maintenance and availability of spare parts. Machines that are easy to clean and maintain will have a longer lifespan and require fewer repairs.

Technology and Features

Modern automatic heat press machines come equipped with advanced technology and features that enhance usability and performance.

Digital Controls and Displays: Digital temperature and time controls allow for precise settings, ensuring consistent results. LCD displays provide clear visibility of settings and status, making the machine user-friendly.

Safety Features: Look for machines with safety features such as automatic shut-off, emergency stop buttons, and heat-resistant handles. These features protect the operator and prevent accidents.

Compatibility with Accessories: Some machines offer compatibility with additional accessories like interchangeable platens, cap attachments, and Teflon sheets. These accessories expand the machine’s versatility and application range.

Price and Budget Considerations

The price range of automatic heat press machines varies widely based on their features, build quality, and brand reputation. It’s essential to balance your budget with the machine’s capabilities to ensure a cost-effective investment.

Entry-Level Machines: Suitable for small businesses or hobbyists. They offer basic features and are generally affordable, ranging from $200 to $500. However, they may lack advanced features and durability.

Mid-Range Machines: Priced between $500 and $1,500, these machines offer a good balance of features, build quality, and performance. They are suitable for growing businesses and provide reliable results for moderate production volumes.

High-End Machines: Priced above $1,500, these machines come with advanced features, robust build quality, and high durability. They are ideal for large-scale production and professional use, offering consistent performance and long-term reliability.

Importance of Safety Standards and Certifications

Safety standards and certifications are paramount when selecting an automatic heat press machine. They ensure the machine’s safe operation and compliance with industry regulations.

Industry Safety Standards

Automatic heat press machines must comply with various industry safety standards to ensure safe operation. These standards include:

CE Certification: Indicates that the machine meets European safety, health, and environmental protection requirements. CE-certified machines are considered safe and reliable.

UL Certification: Ensures that the machine has been tested and meets safety standards set by Underwriters Laboratories. UL certification is crucial for machines used in North America.

ISO Standards: Machines compliant with ISO standards demonstrate adherence to international safety and quality guidelines. ISO certification ensures consistent quality and safety across different markets.

Importance of Manufacturer Warranty

A manufacturer warranty is a critical factor in ensuring the long-term reliability and support for your automatic heat press machine. Warranties cover defects in materials and workmanship, providing peace of mind and protection for your investment.

Warranty Duration: Look for machines with a warranty period of at least one year. Some manufacturers offer extended warranties, which can be beneficial for high-value machines.

Coverage Details: Understand what the warranty covers, including parts, labor, and specific components. Ensure that the warranty includes coverage for critical components like the heating element and digital controls.

After-Sales Support: Evaluate the manufacturer’s after-sales support, including technical assistance, spare parts availability, and repair services. Good after-sales support ensures minimal downtime and efficient resolution of issues.

Regulatory Compliance

Regulatory compliance ensures that the automatic heat press machine adheres to legal and industry standards, providing safe and reliable operation.

Electrical Safety: Machines should comply with electrical safety standards to prevent hazards like electrical shocks and fires. Compliance with standards such as IEC 60335 ensures electrical safety.

Environmental Regulations: Machines should meet environmental regulations regarding energy efficiency and hazardous materials. Compliance with standards like RoHS (Restriction of Hazardous Substances) ensures that the machine does not contain harmful substances.Operational Compliance: Machines should comply with operational standards, including noise levels and ergonomic design. Compliance with standards like OSHA (Occupational Safety and Health Administration) ensures a safe working environment.

Enhancing Efficiency with Advanced Technology

Advanced technology in automatic heat press machines can significantly enhance efficiency and productivity. Here, we explore some of the latest technological advancements.

Smart Automation Features

Smart automation features streamline the heat press process, reducing manual intervention and increasing productivity.

Auto-Open and Auto-Swing: These features automatically open or swing the platen after the transfer is complete, preventing overheating and ensuring consistent results. They are particularly useful in high-volume production environments.

Programmable Settings: Machines with programmable settings allow users to save and recall specific temperature, time, and pressure settings for different materials. This feature enhances efficiency by reducing setup time and ensuring consistent results.

Remote Monitoring and Control: Some advanced machines offer remote monitoring and control capabilities through mobile apps or computer interfaces. This feature allows operators to monitor and adjust settings remotely, improving efficiency and flexibility.

Integration with Other Devices and Systems

Compatibility with other devices and systems enhances the versatility and functionality of automatic heat press machines.

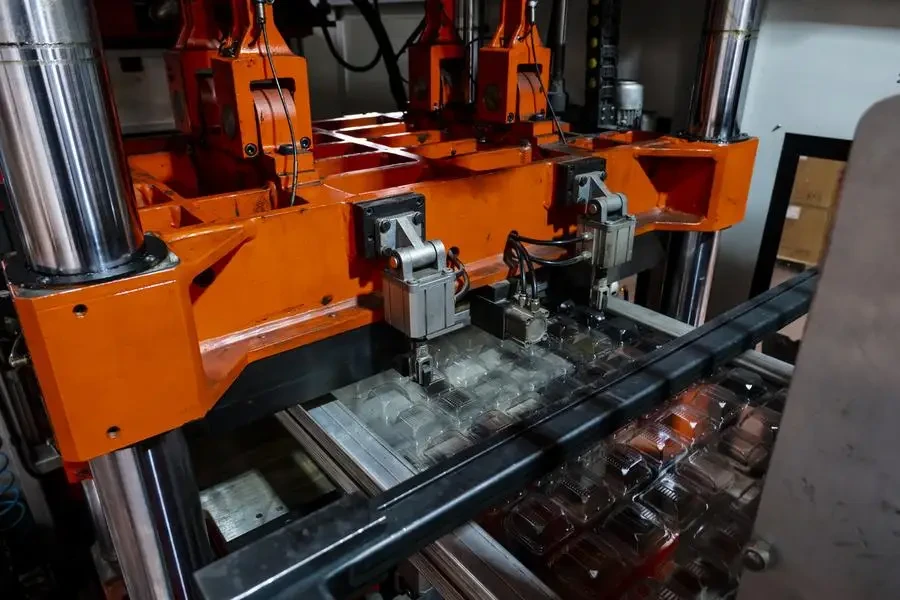

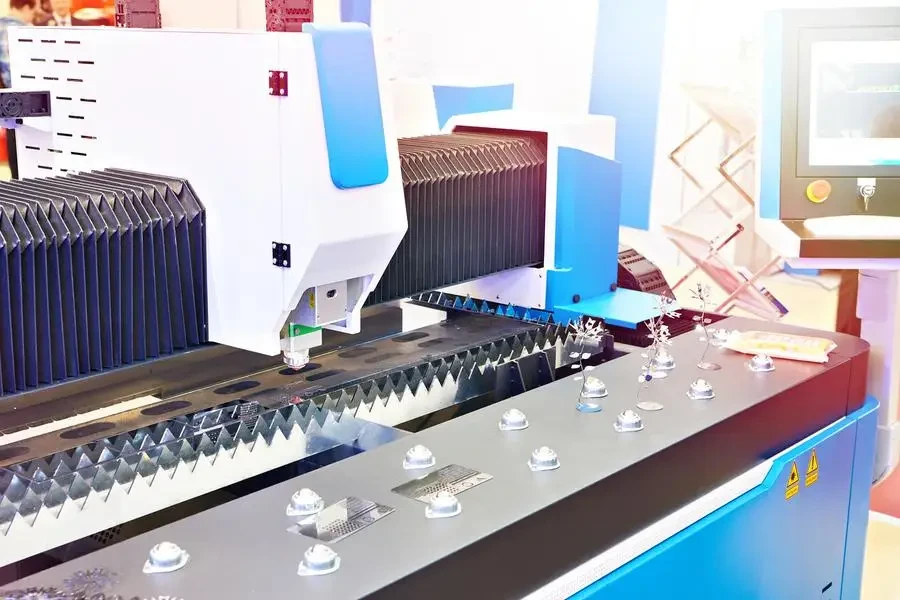

CNC and PLC Integration: Machines integrated with CNC (Computer Numerical Control) or PLC (Programmable Logic Controller) systems offer precise control and automation. These integrations enable complex operations and improve accuracy.

Material Feeding Systems: Integration with automatic material feeding systems enhances productivity by reducing manual handling. These systems ensure consistent material placement and reduce setup time.

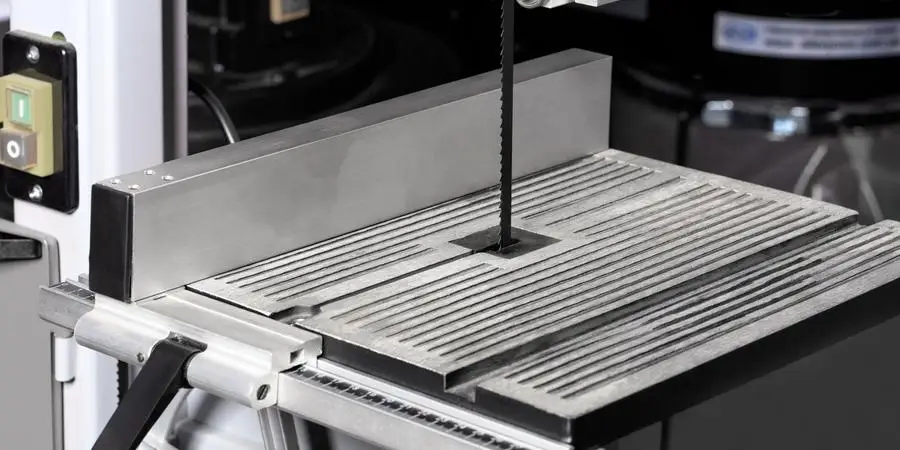

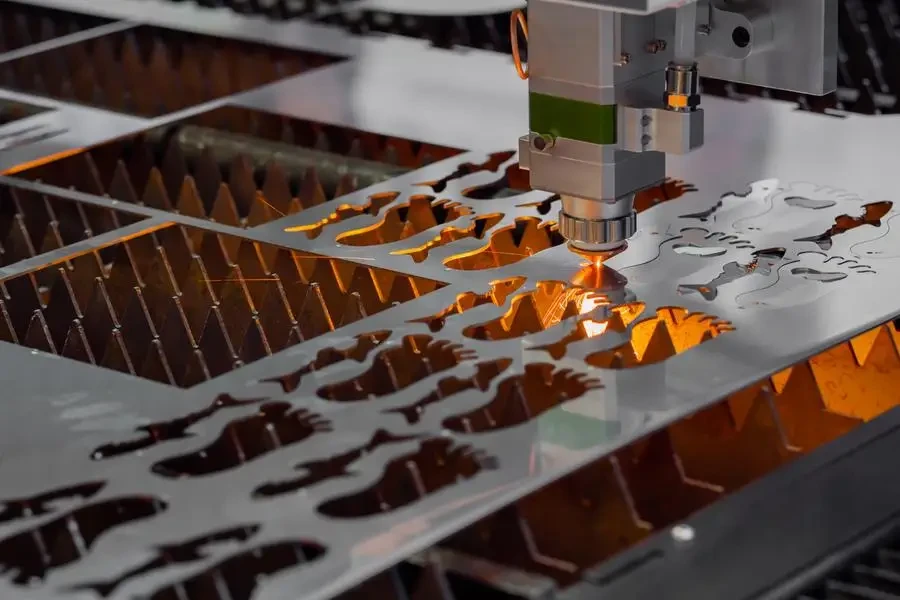

Laser Cutting and Monitoring Systems: Some advanced machines include laser cutting and monitoring systems for precise alignment and cutting. These systems improve accuracy and reduce errors, enhancing overall efficiency.

Energy Efficiency and Sustainability

Energy efficiency and sustainability are crucial considerations for modern automatic heat press machines, reducing operational costs and environmental impact.

Energy-Efficient Heating Elements: Machines with energy-efficient heating elements consume less power while maintaining consistent temperature control. This feature reduces operational costs and supports sustainability efforts.

Eco-Friendly Materials: Machines made from eco-friendly materials and components reduce environmental impact. Look for machines that comply with RoHS and other environmental standards.Low Power Consumption Modes: Some machines offer low power consumption modes for idle periods, reducing energy usage without compromising performance. This feature enhances energy efficiency and reduces operational costs.

Practical Examples of Advanced Features

To illustrate the practical benefits of advanced features in automatic heat press machines, consider the following examples:

Example 1: High-Volume T-Shirt Production: A textile printing company uses an automatic heat press machine with auto-open and programmable settings. The auto-open feature prevents overheating, while programmable settings allow for quick adjustments between different designs. This setup increases production efficiency and ensures consistent results.

Example 2: Custom Apparel Printing: A custom apparel business utilizes a machine with remote monitoring and control capabilities. Operators can monitor and adjust settings remotely, allowing for flexible operation and reducing downtime. This feature enhances productivity and allows for quick responses to customer demands.

Example 3: Eco-Friendly Printing: A sustainable fashion brand invests in an energy-efficient heat press machine with low power consumption modes. The machine’s eco-friendly materials and energy-efficient heating elements reduce operational costs and support the brand’s sustainability goals.

Conclusion

Selecting the right automatic heat press machine involves considering various factors such as types, performance, build quality, technology, safety standards, and price. Advanced features and regulatory compliance enhance efficiency and ensure safe operation. By making an informed decision, businesses can achieve high-quality results and long-term reliability.