In 2024, the global market for metal industry robotics, including laser marking machines, reached $0.77 billion, with projections to grow significantly by 2029. As businesses gear up for 2025, the demand for precision and efficiency in manufacturing is driving the adoption of advanced laser marking technologies. This article delves into the key considerations for selecting laser marking machines for metal, offering insights into the latest trends and innovations shaping the industry.

Table of Contents:

– The Growing Demand for Laser Marking Machines in the Metal Industry

– In-Depth Analysis of the Laser Marking Machines Market

– Key Considerations When Selecting Laser Marking Machines for Metal

– Advanced Features and Innovations in Laser Marking Machines

– Regulatory Compliance and Safety Standards

– Future Trends and Developments in Laser Marking Technology

– Wrapping Up

The Growing Demand for Laser Marking Machines in the Metal Industry

Laser marking machines are becoming increasingly essential in the metal industry due to the demand for precision and efficiency in manufacturing. By 2024, the global market for metal industry robotics, which includes laser marking machines, is expected to reach $0.77 billion. This market is anticipated to grow at a compound annual growth rate (CAGR) of 2.24% from 2024 to 2029, reaching $0.86 billion by 2029. China is leading the market with a projected revenue of $119.9 million in 2024, highlighting its dominant position.

The United States also plays a significant role, with its machinery and equipment market valued at $194.2 billion in 2024, indicating strong demand for advanced machinery, including laser marking technologies. The sector’s output is projected to reach $0.4 trillion, with a growth rate of 0.98% over the next five years. This expansion is driven by rising global demand, ongoing technological advancements, and increased investment in automation and digitalization.

In Germany, the tools and machines market, which includes laser marking machines, is expected to grow at a CAGR of 2.83% from 2024 to 2029. This growth is fueled by the country’s focus on precision engineering and high-quality manufacturing, making Germany a key player in the global market. The positive outlook is further supported by the demand for innovative and environmentally conscious products.

In-Depth Analysis of the Laser Marking Machines Market

When choosing laser marking machines for metal, several critical factors must be considered to ensure optimal performance and return on investment. These include the type of laser technology, power output, marking speed, precision, and compatibility with various metals. Understanding these elements helps businesses make informed decisions tailored to their specific needs.

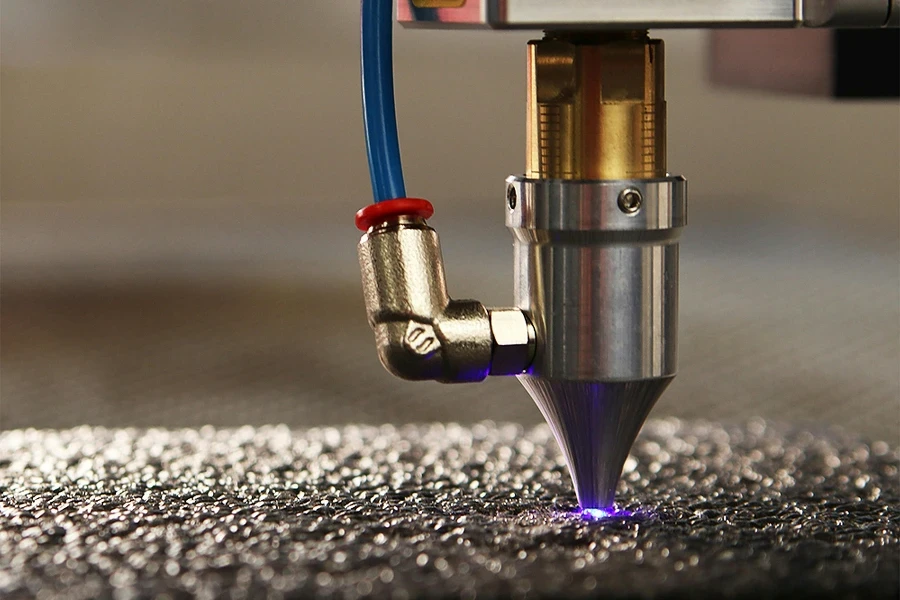

1. Laser Technology Types

The type of laser technology is a fundamental consideration when selecting a laser marking machine for metal. Common types include fiber lasers, CO2 lasers, and Nd:YAG lasers. Fiber lasers are highly efficient and suitable for marking metals due to their excellent beam quality and energy efficiency. They are particularly effective for marking stainless steel, aluminum, and other metals. CO2 lasers, while versatile, are less effective on metals without additional treatments. Nd:YAG lasers, known for their high peak power, are ideal for deep engraving and marking on hard metals. Each laser type offers distinct advantages, and the choice depends on specific application requirements.

2. Power Output and Speed

Power output is crucial as it determines the machine’s ability to mark different metals. Higher power output allows for faster marking speeds and deeper engravings, essential for industrial applications requiring high throughput. For instance, a 50W fiber laser can efficiently mark metals at high speeds, making it suitable for mass production. However, higher power also means increased energy consumption, so it’s important to balance power needs with operational costs. Additionally, the marking speed should align with production demands to ensure efficiency without compromising quality.

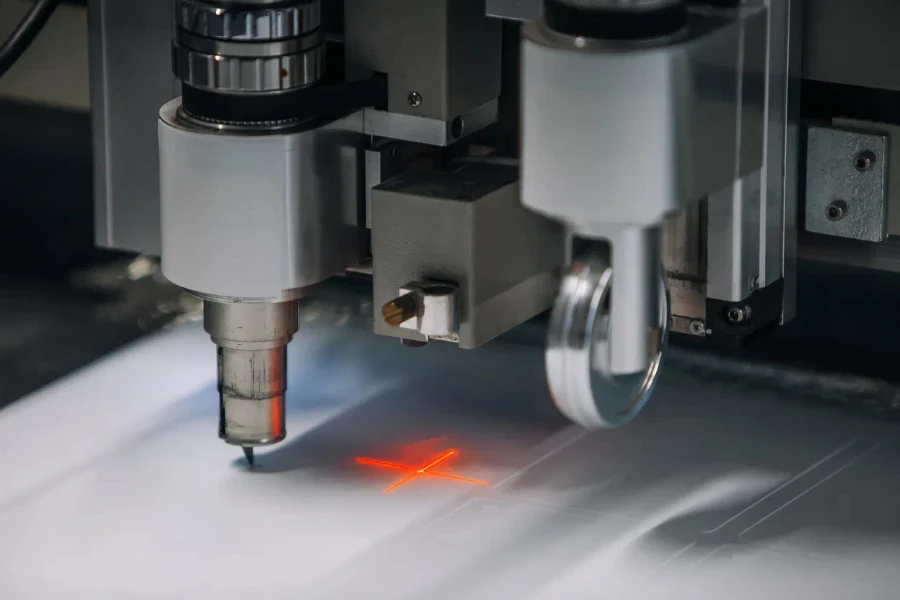

3. Precision and Accuracy

Precision and accuracy are vital for applications requiring detailed and intricate designs. The laser marking machine should offer high-resolution capabilities to produce clear and precise marks. This is particularly important in industries such as aerospace and medical devices, where markings must meet stringent quality standards. Machines equipped with advanced optics and beam delivery systems can achieve superior precision, ensuring even the smallest details are accurately reproduced. Evaluating the machine’s resolution and repeatability specifications can provide insights into its precision capabilities.

4. Compatibility with Various Metals

The compatibility of the laser marking machine with different metals is another important factor. Some machines are optimized for specific metals, while others offer versatility across a range of materials. For example, fiber lasers are well-suited for marking metals like stainless steel, titanium, and brass, while Nd:YAG lasers can handle harder metals such as tungsten and carbide. Understanding the types of metals that need to be marked will guide the selection of the appropriate laser technology and machine configuration.

5. Maintenance and Support

Maintenance requirements and support services are critical for ensuring the longevity and reliability of laser marking machines. Machines with minimal maintenance needs and robust support services can reduce downtime and operational disruptions. It’s important to assess the availability of spare parts, technical support, and warranty options. Manufacturers that offer comprehensive after-sales support, including training and maintenance services, provide added value and peace of mind to businesses investing in laser marking technology.

Key Considerations When Selecting Laser Marking Machines for Metal

When choosing laser marking machines for metal, several critical factors must be considered to ensure optimal performance and return on investment. These include the type of laser technology, power output, marking speed, precision, and compatibility with various metals. Understanding these elements helps businesses make informed decisions tailored to their specific needs.

1. Laser Technology Types

The type of laser technology is a fundamental consideration when selecting a laser marking machine for metal. Common types include fiber lasers, CO2 lasers, and Nd:YAG lasers. Fiber lasers are highly efficient and suitable for marking metals due to their excellent beam quality and energy efficiency. They are particularly effective for marking stainless steel, aluminum, and other metals. CO2 lasers, while versatile, are less effective on metals without additional treatments. Nd:YAG lasers, known for their high peak power, are ideal for deep engraving and marking on hard metals. Each laser type offers distinct advantages, and the choice depends on specific application requirements.

2. Power Output and Speed

Power output is crucial as it determines the machine’s ability to mark different metals. Higher power output allows for faster marking speeds and deeper engravings, essential for industrial applications requiring high throughput. For instance, a 50W fiber laser can efficiently mark metals at high speeds, making it suitable for mass production. However, higher power also means increased energy consumption, so it’s important to balance power needs with operational costs. Additionally, the marking speed should align with production demands to ensure efficiency without compromising quality.

3. Precision and Accuracy

Precision and accuracy are vital for applications requiring detailed and intricate designs. The laser marking machine should offer high-resolution capabilities to produce clear and precise marks. This is particularly important in industries such as aerospace and medical devices, where markings must meet stringent quality standards. Machines equipped with advanced optics and beam delivery systems can achieve superior precision, ensuring even the smallest details are accurately reproduced. Evaluating the machine’s resolution and repeatability specifications can provide insights into its precision capabilities.

4. Compatibility with Various Metals

The compatibility of the laser marking machine with different metals is another important factor. Some machines are optimized for specific metals, while others offer versatility across a range of materials. For example, fiber lasers are well-suited for marking metals like stainless steel, titanium, and brass, while Nd:YAG lasers can handle harder metals such as tungsten and carbide. Understanding the types of metals that need to be marked will guide the selection of the appropriate laser technology and machine configuration.

5. Maintenance and Support

Maintenance requirements and support services are critical for ensuring the longevity and reliability of laser marking machines. Machines with minimal maintenance needs and robust support services can reduce downtime and operational disruptions. It’s important to assess the availability of spare parts, technical support, and warranty options. Manufacturers that offer comprehensive after-sales support, including training and maintenance services, provide added value and peace of mind to businesses investing in laser marking technology.

Advanced Features and Innovations in Laser Marking Machines

The laser marking industry is continuously evolving, with new technologies and features enhancing machine capabilities. Understanding these advancements can help businesses leverage the latest innovations for improved performance and efficiency.

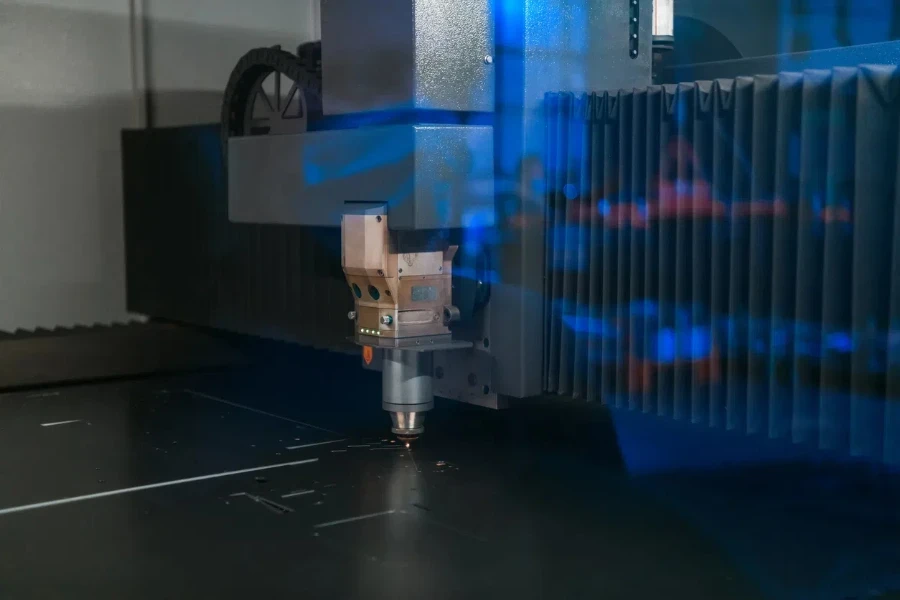

Integration with Automation Systems

Modern laser marking machines often feature integration capabilities with automation systems, allowing for seamless operation within production lines. This integration can include robotic arms for material handling, conveyor systems for continuous marking, and software interfaces for real-time monitoring and control. Automation not only increases productivity but also ensures consistent quality by reducing human error. Businesses looking to optimize their manufacturing processes should consider machines with advanced automation features.

Enhanced Software Capabilities

Software plays a crucial role in the functionality and versatility of laser marking machines. Advanced software solutions offer features such as variable data marking, barcode generation, and 3D marking capabilities. These features enable businesses to customize markings for different applications, from simple text to complex graphics. Additionally, user-friendly interfaces and compatibility with various file formats can streamline the design and marking process, making it accessible to operators with varying levels of expertise.

Energy Efficiency and Environmental Impact

Energy efficiency is becoming increasingly important in the selection of industrial equipment, including laser marking machines. Energy-efficient machines not only reduce operational costs but also minimize environmental impact. Innovations such as eco-mode settings, which reduce power consumption during idle times, and the use of energy-efficient laser sources contribute to sustainability goals. Businesses committed to reducing their carbon footprint should prioritize machines with energy-efficient features.

Regulatory Compliance and Safety Standards

Compliance with regulatory standards and safety requirements is essential when selecting laser marking machines for metal. Ensuring that machines meet industry-specific regulations can prevent legal issues and enhance workplace safety.

Industry-Specific Regulations

Different industries have specific regulations regarding the marking of metal components. For example, the aerospace industry requires compliance with standards such as AS9100 for traceability and quality assurance. Similarly, medical device manufacturers must adhere to FDA regulations for product identification. Selecting a laser marking machine that meets these industry-specific standards is crucial for maintaining compliance and ensuring product integrity.

Safety Features and Certifications

Safety is a paramount concern when operating laser marking machines. Machines should be equipped with safety features such as protective enclosures, interlock systems, and emergency stop functions to prevent accidents and injuries. Additionally, certifications such as CE marking and ISO standards indicate that the machine meets international safety and quality benchmarks. Businesses should prioritize machines with comprehensive safety features and certifications to protect operators and maintain a safe working environment.

Environmental and Health Considerations

Laser marking processes can generate fumes and particulates that may pose health risks to operators. Machines equipped with effective fume extraction and filtration systems can mitigate these risks by removing harmful emissions from the work area. Additionally, compliance with environmental regulations regarding waste disposal and emissions is essential for sustainable operations. Businesses should evaluate the environmental and health considerations of laser marking machines to ensure a safe and compliant workplace.

Future Trends and Developments in Laser Marking Technology

The laser marking industry is poised for significant advancements, driven by technological innovations and evolving market demands. Understanding these trends can help businesses stay ahead of the curve and capitalize on emerging opportunities.

Miniaturization and Portability

As technology advances, there is a growing trend towards miniaturization and portability in laser marking machines. Compact and portable machines offer flexibility and convenience, allowing businesses to perform marking operations in various locations. This trend is particularly relevant for industries such as automotive and aerospace, where on-site marking is often required. Portable machines with battery-powered options and wireless connectivity are expected to gain popularity in the coming years.

Integration of Artificial Intelligence

Artificial intelligence (AI) is increasingly being integrated into laser marking machines to enhance performance and efficiency. AI algorithms can optimize marking parameters, improve precision, and predict maintenance needs, reducing downtime and operational costs. Additionally, AI-powered vision systems can enable real-time quality inspection, ensuring that markings meet quality standards. The integration of AI is set to revolutionize the laser marking industry, offering new levels of automation and intelligence.

Expansion of Application Areas

The application areas for laser marking machines are expanding beyond traditional industries. Emerging sectors such as electronics, renewable energy, and additive manufacturing are increasingly adopting laser marking technology for product identification and traceability. This expansion is driven by the need for high-quality, durable markings that can withstand harsh environments and complex manufacturing processes. Businesses in these emerging sectors should explore the potential of laser marking machines to enhance their operations and product offerings.

Wrapping Up

Selecting the right laser marking machine for metal involves careful consideration of various factors, including laser technology, power output, precision, and regulatory compliance. By staying informed about the latest advancements and trends, businesses can make strategic decisions that enhance their manufacturing capabilities and competitiveness.