In addition to the cost of electricity, the price of hydrogen depends largely on the up-front investment cost of the electrolyzer. The lower the full-load hours, the greater the impact. Analyst BloombergNEF (BNEF) sees a number of different possible pathways for the market to develop.

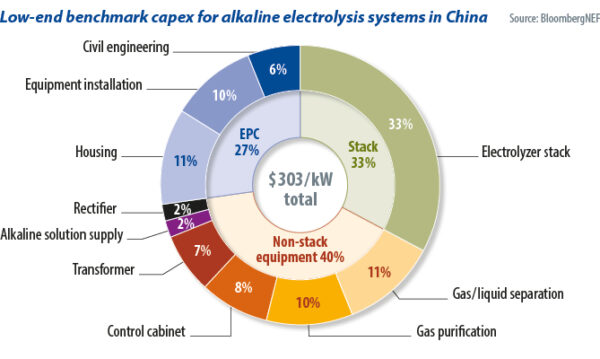

All electrolyzers have a technology-specific stack at their center, in which water is split into hydrogen and oxygen. This consists of carefully layered, gas-tight, welded bipolar plates and plastic membranes – among the main cost factors in every electrolysis plant. Xiaoting Wang, an analyst at BloombergNEF, spoke to 20 companies worldwide as part of the company’s “Electrolysis System Capex [capital expenditure] could drop 30% by 2025” study. This gave her an insight into the cost structure for 30 projects and made it possible to determine the price components for a 10 MW alkaline electrolysis plant in China in 2021, as an example.

The stack accounted for around 33% of the total costs, said Wang, with 40% of the costs coming from the other technical equipment, including power electronics, gas and liquid separation, and gas purification (see chart below). A further 27% of the costs were attributable to other project expense, such as civil engineering, equipment installation, and housing.

Chinese alkaline

The BNEF report stated a 10 MW alkaline system often consists of two stacks of 5 MW that deliver hydrogen at 16 bar. The manufacturer usually offers a complete solution with all accessories and installation. Chinese developers received such an offer in 2021 for as little as $303/kW – that is, a total of around €3 million ($3.2 million). This did not include the grid-connection fee, high-voltage transformers, or other “soft” costs such as expenses for development, approvals and financing agreements.

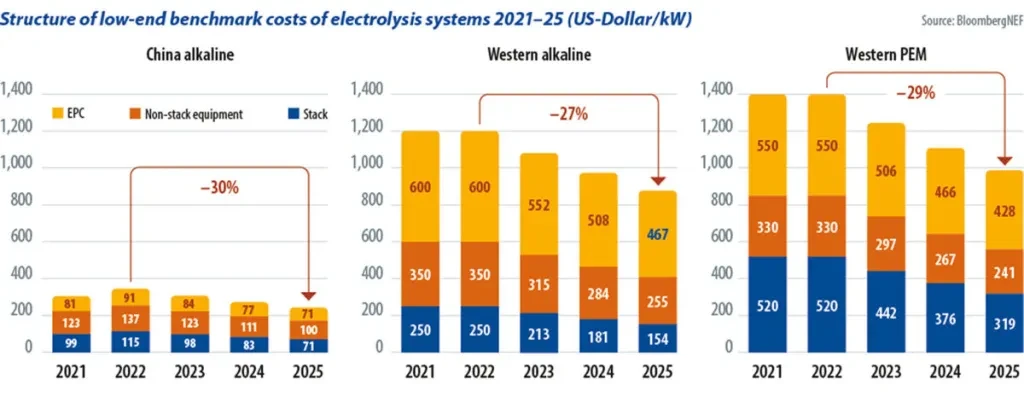

Wang said that the project costs in Western markets with domestically produced electrolyzers are around four times as high. Investment costs averaged €1,200/kW for alkaline electrolyzers and €1,400/kW for proton exchange membrane (PEM) electrolyzers.

Cheaper offers, such as €180/kW, from Peric for an 80 MW plant in China; or €521/kW, from Thyssenkrupp for a 2 GW plant in Saudi Arabia, do not include all project costs and are, therefore, not comparable. They do include electrolysis stacks, gas liquid separation and purification, and the water supply. However, power electronics and control cabinets are excluded.

Wang attributed this large price difference to low labor costs and the established supply chains in China, where manufacturers of electrolyzers can source materials and components at much lower prices than in the West. Thus far, the production of most electrolyzers is not automated. Chinese manufacturers were producing megawatt-scale electrolyzers for other industries before there was demand from green hydrogen producers, meaning they benefited from scaled production. Existing customers included manufacturers of polysilicon for photovoltaic cells.

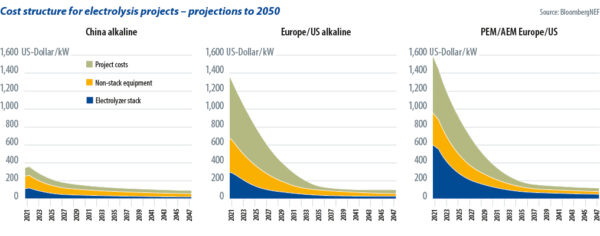

The Bloomberg analysis, from September 2022, claimed that Western manufacturers could achieve similarly low costs. To do so, they would have to utilize highly automated production. Wang said she anticipates significant price reductions by as early as 2025 (see main chart above). Prices for 2021 also still included adequate margins for engineering, procurement, and construction (EPC) companies. Long-term development shows that prices for electrolysis projects will converge worldwide from 2035.

Western investors tend to entrust an EPC company with the handling of an entire project for a lump sum, and to rely on large, well-known companies. Such companies usually have little experience in the construction of electrolysis plants, however, so the safety premiums in the price of the overall offer are high. With increasing experience and the entry of specialized project planners, which leads to more competition, these surcharges should decrease.

Prefabricated containers

Equipment suppliers are also endeavoring to offer products that reduce the workload on the construction site, and thus cut costs. One trend that supports this is the development of containerized systems. This means that the various system components do not have to be assembled on site but are instead prefabricated in a factory, tested, and delivered to the intended location. This minimizes sources of error and reduces the deployment time of specialist personnel on site.

In an update to its market analysis, Bloomberg reported on offers for such container solutions for $1,000/kW. Industry insiders have even reported offers as low as $700/kW, said Wang. One such container solution was presented in a pv magazine Germany webinar in February 2023. The PEM electrolyzer from German supplier H-Tec has an output of 1 MW and produces 450 kg of hydrogen per day. Recordings of pv magazine webinars are available at pv-magazine.com/webinars.

Those who want to reduce costs by purchasing an electrolyzer from China need to consider that exported products are usually sold at a premium of around 20% to 30%, compared to prices on the domestic market, said BloombergNEF, meaning that development and project planning costs would still be higher. It is important to consider that choosing a Chinese brand to supply the core equipment could reduce a project’s chance of receiving local subsidies and could affect financing.

The first green hydrogen projects were, and still are, mainly designed to draw electricity from the grid, with the electrolyzers’ electricity consumption balanced monthly or annually against the suppliers’ renewable electricity generation. In this case, the technical disadvantage of alkaline electrolysis in terms of flexibility would not bother operators.

However, after 2030, most new green hydrogen projects will need to ensure an hourly match between power generation and power consumption for grid-connected electrolysis systems, which will lead to more off-grid projects being developed, said Wang. This trend is not only due to the need for a clearer definition of green hydrogen. A direct connection to renewables generation plants should also improve economic feasibility in the future. After all, using the grid to shift huge amounts of electricity will cost more in the future. Electrolysis with stable grid electricity will, therefore, not be able to produce cheaper hydrogen in the future than with solar and wind energy, with their low electricity generation costs.

Cost reduction

This is where PEM electrolyzers come into play. These can better follow the fluctuating electricity supply and also work efficiently in partial load operation or off-grid. However, this technology still needs to significantly reduce its dependence on expensive platinum group metals, especially iridium, in order to gain a dominant market share, said Wang. Plug Power, from the United States, and ITM Power, from the United Kingdom, use 200 grams to 300 grams of iridium per megawatt of capacity.

Current worldwide production of iridium is around seven metric tons per year. Even if the entire volume were used to produce catalysts for PEM electrolysis, this supply chain could only support a maximum of 35 GW per year. PEM can only dominate the green hydrogen market if manufacturers manage to significantly reduce the consumption of iridium per unit this decade or achieve an equivalent effect in parallel with improved metal recycling. Wang said Electric Hydrogen, a new United States-based manufacturer of PEM electrolyzers, has already reported using significantly less iridium than competitors.

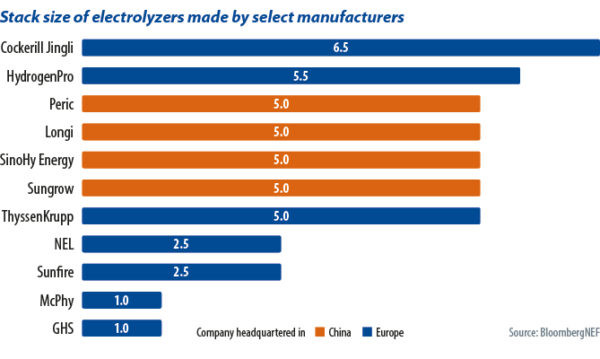

There is also a chance that anion exchange membrane (AEM) electrolysis could replace PEM after 2030 because it does not use expensive metals. This means manufacturers must succeed in developing stacks that are suitable for large scale projects. Enapter is an AEM pioneer, building small stacks and assembling them into larger 1 MW units which are still small compared to other electrolyzers. California-based company Verdagy is just starting to sell 20 MW modules, each consisting of two 10 MW stacks.

Larger stacks

Producing more hydrogen from a single stack is another route to cost reduction. One way to achieve this is by increasing the size of the stack itself. The largest commercial stack, with 15 MW, which came onto the market in September 2023, comes from Longi, according to Wang. Although increasing the size of the stack sounds straightforward, it has several disadvantages. First, it becomes more difficult to move large units, especially for international sales. Second, with larger units, mechanical forces and stresses become more uneven, which affects safety and is associated with lower efficiency.

More yield can be achieved by increasing the current density. Put simply, the more electrons that pass through the stack, the more hydrogen can be produced. Simply applying a higher voltage can increase the current density but has a detrimental effect on efficiency. The strategy to maintain or even increase efficiency is to revise the internal structures and introduce advanced catalysts and membranes.

Over the long term, it is preferable to increase the current density, said Wang. Plug Power and ITM Power are in the lead here with a current density of more than 3A/cm2 (amperes per cm2) followed by AEM manufacturer Verdagy, with 2A/cm2. Most Chinese alkaline electrolyzers have only 0.3A/cm2. Wang, in turn, has learned from Electric Hydrogen that their product would have an even higher current density than Plug Power and ITM Power. She estimated that, by 2030, current densities close to 10A/cm2 will be typical for the remaining manufacturers of PEM electrolyzers.

More competition

The costs of Western products could initially fall by around 30% by 2025. In addition to technological progress, competition is also likely to increase. Manufacturers worldwide have announced a production capacity of 52.6 GW for this year while deliveries are optimistically only 5 GW, according to BloombergNEF’s forecast. In China, where there is already fierce competition for orders from project developers, manufacturers’ margins are small. In addition, developers hedge their risk against the manufacturer by paying only up to 85% of the agreed price on delivery and the rest once commissioning has been completed and performance is still good after 18 months.

The pressure is not yet as high on Western markets, as investors and project developers in Europe and the United States can reckon with relatively high subsidies. However, production capacities are also increasing here and factories need to be fully utilized. If Chinese manufacturers also seek their salvation in exports, it is foreseeable that the price war will increase in all markets.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Source from pv magazine

Disclaimer: The information set forth above is provided by pv-magazine.com independently of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller and products.