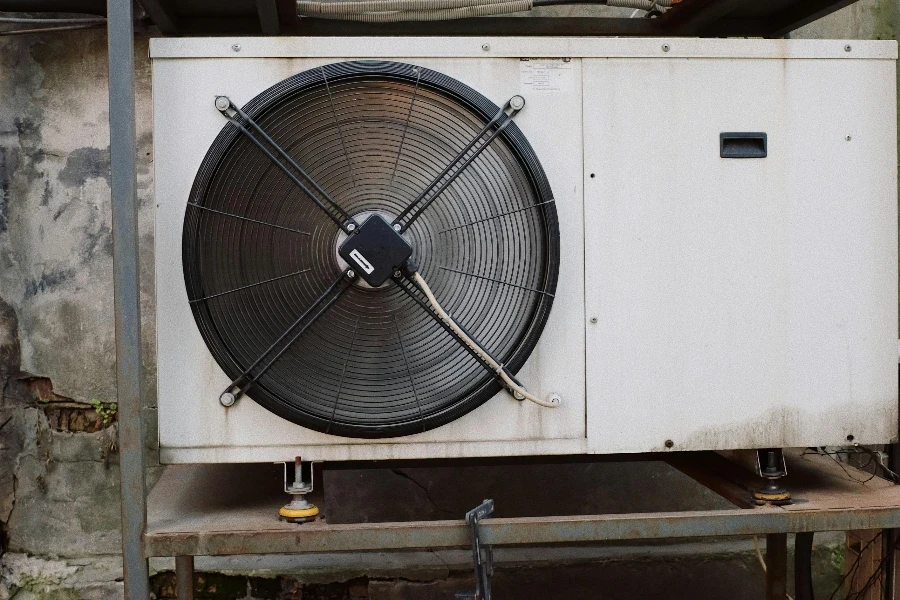

In 2025, advancements in HVAC technology have revolutionized energy efficiency and performance. This article delves into the key aspects of choosing the right Compressor HVAC System, offering valuable insights for wholesalers, retailers, and purchasing professionals. The guidance provided here aims to enhance decision-making and ensure long-term reliability and efficiency in HVAC solutions.

Table of Contents:

-Market Overview: Compressor HVAC Systems

-Detailed Introduction and Analysis of the Compressor HVAC System Market

-Key Factors When Selecting a Compressor HVAC System

-Design and Considerations

-Advancements in Compressor HVAC Technology

-Conclusion

Market Overview: Compressor HVAC Systems

The global market for compressor HVAC systems is experiencing significant growth due to industrialization, technological advancements, and the rising demand for energy-efficient solutions. In 2024, the market was valued at USD 45.89 billion and is projected to reach USD 65.96 billion by 2030, growing at a compound annual growth rate (CAGR) of 6.21%. This growth is driven by the increasing adoption of HVAC systems across residential, commercial, automotive, and industrial sectors.

Regionally, the Americas, particularly North America, dominate the market due to stringent energy efficiency regulations and the widespread adoption of advanced HVAC technologies. The U.S. Environmental Protection Agency’s (EPA) regulations, such as the Significant New Alternatives Policy (SNAP), encourage manufacturers to develop environmentally friendly refrigerant compressors. In the Asia-Pacific region, rapid industrialization and urbanization in countries like China and India are fueling HVAC system demand. Europe also plays a significant role, emphasizing energy efficiency and sustainable practices, with countries like Germany and France leading in green technology adoption.

The market segmentation includes various types of compressors such as centrifugal, reciprocating, rotary vane, and screw compressors, catering to different applications and cooling capacities. The demand for eco-friendly refrigerants like R-32 and R-410A is rising, aligning with global sustainability goals. Innovations in electric vehicle technology have further propelled the development of specialized compressor systems for EVs, contributing to market expansion.

Detailed Introduction and Analysis of the Compressor HVAC System Market

Compressor HVAC systems are crucial for maintaining optimal indoor air quality and temperature control in both residential and commercial buildings. The market offers a diverse range of products, including hermetic, open, and semi-hermetic compressors, each designed to meet specific operational requirements. Efficient operation of these systems is essential for energy conservation and optimizing cooling capacities, making them a vital component in modern HVAC solutions.

Key performance benchmarks for compressor HVAC systems include energy efficiency, cooling capacity, and reliability. Market dynamics are influenced by the rising production and sales of electric vehicles, government initiatives promoting energy-efficient HVAC systems, and the increasing use of these systems in large-scale oil and gas exploration activities. Consumer behavior is shifting towards smart HVAC systems with IoT-enabled remote monitoring and predictive maintenance features, driven by the demand for smart appliances that offer enhanced convenience and operational efficiency.

Distribution channels for compressor HVAC systems are evolving, with a notable preference for direct sales and e-commerce platforms. Manufacturers are developing cost-efficient models to cater to price-sensitive markets. Recent innovations include oil-free and variable-speed compressors, which offer improved energy efficiency and reduced maintenance requirements. The product lifecycle stages of compressor HVAC systems are being extended through continuous advancements in technology and materials, ensuring long-term reliability and performance.

Digitalization is significantly impacting the HVAC industry, with AI and machine learning technologies enabling more precise climate control and energy management. Social trends indicate growing awareness of indoor air quality, leading to increased demand for HVAC systems with advanced air purification features. Customer pain points such as high initial costs and frequent maintenance requirements are being addressed through innovative solutions and strategic brand positioning.

In summary, the compressor HVAC system market is poised for substantial growth in the coming years, driven by technological advancements, regulatory support, and evolving consumer preferences. Manufacturers are focusing on differentiation strategies, such as developing eco-friendly and energy-efficient products, to gain a competitive edge in this dynamic market.

Key Factors When Selecting a Compressor HVAC System

Choosing the right compressor HVAC system is crucial for optimal performance, energy efficiency, and longevity. Several factors must be considered to make an informed decision that aligns with your specific requirements.

Types of Compressors

Different types of compressors are available, each with unique advantages and limitations. The main types include piston, rotary, screw, scroll, and centrifugal compressors.

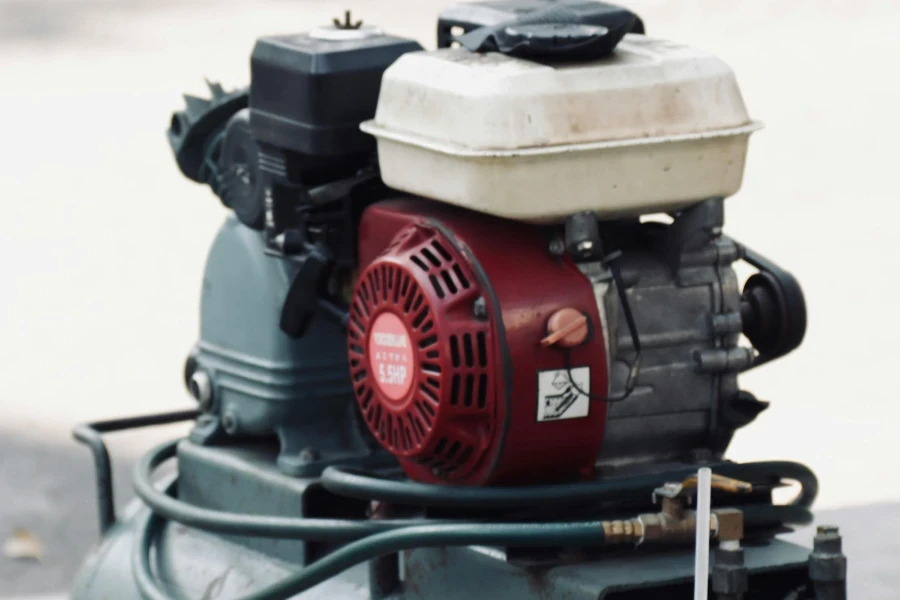

Piston Compressors

Piston compressors, also known as reciprocating compressors, use a piston and cylinder arrangement to compress the refrigerant. These compressors are known for their high-pressure capabilities and large power output range. They are suitable for applications requiring high pressure but have higher maintenance costs and potential vibrational issues. Their simple design makes them easy to install, but they are not ideal for continuous full-capacity operation.

Rotary Compressors

Rotary compressors employ two rotating elements, similar to gears, to compress the refrigerant. They are highly efficient due to the simultaneous intake and compression of refrigerant. Rotary compressors have low initial and maintenance costs and are forgiving in dirty environments. However, they are limited to smaller volumes of gas and produce less pressure compared to other types.

Screw Compressors

Screw compressors use a pair of helical rotors to compress the refrigerant. These compressors are known for their ability to produce high pressure for small quantities of gas while consuming less power than reciprocating compressors. They have fewer moving parts and moderate initial and maintenance costs but are less effective in dirty environments and have high rotational speeds.

Scroll Compressors

Scroll compressors utilize two offset spiral disks to compress the refrigerant. These compressors are quiet, smooth-operating, and highly efficient. They are often used in automobile air conditioning systems and commercial chillers. However, their fully hermetic design makes them difficult to repair, and they typically cannot rotate in both directions.

Centrifugal Compressors

Centrifugal compressors use an impeller wheel to exert centrifugal force on the refrigerant. They are well-suited for compressing large volumes of refrigerant to relatively low pressures. Centrifugal compressors are energy-efficient when operating multiple stages but require larger installation spaces and have higher initial costs.

Performance and Efficiency

When selecting a compressor HVAC system, performance and efficiency are critical considerations. The system should meet the cooling or heating requirements of the application while minimizing energy consumption.

Capacity

The capacity of a compressor is measured in British Thermal Units per hour (Btu/hr) and indicates its ability to remove heat from the refrigerant gas. The nominal capacity ratings are based on standard conditions, including condensing temperature, evaporative temperature, refrigerant type, and motor revolutions per minute (rpm).

Energy Efficiency Ratio (EER)

The Energy Efficiency Ratio (EER) measures the efficiency of the compressor by comparing the cooling capacity to the power input. A higher EER indicates a more efficient system. Selecting a compressor with a high EER can result in significant energy savings over the system’s lifespan.

Variable Speed

Variable speed compressors adjust their operating speed based on the cooling demand, resulting in better energy efficiency and reduced wear and tear. These compressors can operate at lower speeds during periods of low demand, reducing energy consumption and extending the system’s lifespan.

Technical Specifications

Understanding the technical specifications of compressor HVAC systems is essential for ensuring compatibility with your application requirements.

Condensing Temperature

The condensing temperature range indicates the temperatures over which the compressor is rated to operate. It is crucial to select a compressor that can handle the expected ambient temperatures of the installation environment.

Evaporating Temperature

The evaporating temperature range specifies the temperatures over which the compressor can evaporate the refrigerant. This parameter is vital for applications requiring specific temperature control.

Flow Rate

The flow rate, measured in pounds per hour (lb/hr) or kilograms per hour (kg/hr), indicates the rate at which the refrigerant passes through the compressor. Ensuring the flow rate matches the system’s requirements is essential for optimal performance.

Durability and Build Quality

The durability and build quality of a compressor HVAC system directly impact its lifespan and reliability. High-quality materials and robust construction are crucial for ensuring long-term performance, especially in demanding applications.

Materials

Compressors should be constructed from durable materials resistant to corrosion and wear. Common materials include stainless steel, aluminum, and high-grade plastics. The choice of materials should align with the specific application and environmental conditions.

Sealing and Lubrication

Proper sealing and lubrication are essential for preventing leaks and ensuring smooth operation. Compressors can be open, hermetic, or semi-hermetic. Open compressors have separate housings for the compressor and motor, while hermetic compressors seal both components in a single housing, preventing leaks. Semi-hermetic compressors allow for maintenance and repair, offering a balance between durability and serviceability.

Safety Standards and Certifications

Compliance with safety standards and certifications ensures that the compressor HVAC system meets industry regulations and operates safely.

Certifications

Certifications such as the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) standards and ISO certifications indicate that the compressor meets specific performance and safety criteria. Selecting a certified compressor ensures reliability and adherence to industry standards.

Safety Features

Safety features such as thermal shutoff, which prevents the compressor from overheating, and low noise operation, which reduces noise pollution, are essential for safe and comfortable operation. Ensuring the compressor includes these features can enhance overall system performance and user satisfaction.

Design and Considerations

While functionality and performance are paramount, the design of the compressor HVAC system can also play a role in the selection process.

Compact and Lightweight Designs

Compact and lightweight compressors are ideal for applications with limited space or weight constraints. These designs facilitate easier installation and maintenance, making them suitable for residential and commercial settings.

Noise Reduction

Compressors designed with noise reduction features, such as soundproof enclosures or quieter operation mechanisms, are beneficial for environments where noise levels must be minimized. These designs enhance user comfort and reduce noise pollution.

Customization Options

Some manufacturers offer customization options, allowing buyers to tailor the compressor’s design and features to their specific needs. Customization can include color options, additional features, or specific dimensions to fit unique installation requirements.

Advancements in Compressor HVAC Technology

Technological advancements continue to drive improvements in compressor HVAC systems, enhancing performance, efficiency, and user experience.

Smart Technology Integration

Integration with smart technology enables remote monitoring and control of compressor HVAC systems. Smart thermostats, sensors, and mobile apps allow users to optimize system performance, monitor energy usage, and receive maintenance alerts, enhancing overall efficiency and convenience.

Eco-Friendly Refrigerants

The use of eco-friendly refrigerants, such as hydrofluoroolefins (HFOs), reduces the environmental impact of compressor HVAC systems. These refrigerants have lower global warming potential (GWP) and are safer for the environment, aligning with sustainability goals.

Enhanced Energy Recovery

Advanced energy recovery systems, such as heat recovery ventilators (HRVs) and energy recovery ventilators (ERVs), improve the efficiency of compressor HVAC systems by capturing and reusing waste heat. These systems reduce energy consumption and lower operating costs, contributing to a more sustainable operation.

Conclusion

Selecting the right compressor HVAC system involves considering various factors, including types of compressors, performance and efficiency, technical specifications, durability, safety standards, design, and technological advancements. By thoroughly evaluating these factors, buyers can make informed decisions that ensure optimal performance, energy efficiency, and long-term reliability of their compressor HVAC systems.