The agricultural machinery market is evolving rapidly with a surge in innovative solutions. In 2025, the demand for Three Point Quick Hitches is driven by technological advancements and sustainable farming practices. This article provides a comprehensive guide for professional buyers on selecting the best hitch, emphasizing compatibility, build quality, and advanced features, ensuring informed purchasing decisions for optimal efficiency.

Table of Contents:

-Market Overview: Understanding the Three Point Quick Hitch Market

-Detailed Analysis of the Three Point Quick Hitch Market

-Challenges and Opportunities in the Three Point Quick Hitch Market

-Key Factors When Selecting A Three Point Quick Hitch

-Understanding the Importance of Material Selection

-Enhancing Efficiency with Advanced Features

-Conclusion

Market Overview: Understanding the Three Point Quick Hitch Market

The global market for Three Point Quick Hitches is experiencing notable growth, driven by increasing mechanization in agriculture and the need for efficient farming solutions. The agricultural machinery sector, including the Three Point Quick Hitch market, is projected to grow significantly, with substantial contributions from North America, Europe, and Asia-Pacific. By 2025, the agricultural tractor market, which heavily relies on Three Point Quick Hitches, is expected to grow at a compound annual growth rate (CAGR) of 3.76% from 2023 to 2029.

The Three Point Quick Hitch market is segmented by application, types, and geographical distribution. Primary applications include agriculture, landscaping, and utility tasks. Types are categorized by load capacity and compatibility with various tractor models. A significant portion of demand comes from the APAC region, where smallholder farmers are increasingly adopting mechanized solutions to enhance productivity.

Market dynamics are influenced by technological advancements, government policies promoting agricultural mechanization, and the rising trend of sustainable farming practices. Innovations like GPS integration and tractor automation are driving demand for efficient hitch systems. Moreover, government subsidies and favorable policies in countries like India and China are expected to boost the adoption of Three Point Quick Hitches.

Detailed Analysis of the Three Point Quick Hitch Market

The Three Point Quick Hitch market is evolving rapidly, with several key performance benchmarks and innovations shaping its trajectory. The market is highly competitive, with leading players like Deere & Company, CNH Industrial, and Kubota Corporation dominating the landscape. These companies are investing in research and development to introduce advanced hitch systems that offer enhanced compatibility, ease of use, and durability.

Recent innovations include the integration of digital technologies such as GPS and IoT, enabling real-time monitoring and precision farming. These advancements are expected to improve farming efficiency, increasing the adoption of Three Point Quick Hitches. Additionally, the market is shifting towards eco-friendly and energy-efficient solutions, with manufacturers focusing on developing hitches compatible with electric and hybrid tractors.

Consumer behavior is also changing, with a growing preference for automated and smart farming solutions. Farmers seek equipment that enhances productivity, reduces manual labor, and lowers operational costs. The rising awareness of sustainable farming practices is further driving demand for advanced hitch systems that support eco-friendly initiatives.

Distribution channels play a crucial role, with a preference for both direct sales and dealership networks. Strong after-sales service and support significantly influence purchasing decisions. Manufacturers are expanding their distribution networks and enhancing service offerings to meet growing demand.

Challenges and Opportunities in the Three Point Quick Hitch Market

Despite promising growth prospects, the Three Point Quick Hitch market faces several challenges. High initial investment and maintenance costs for advanced hitch systems can be barriers for small and medium-sized farmers. Additionally, the market is susceptible to fluctuations in agricultural commodity prices, impacting farmers’ purchasing power and demand for agricultural machinery.

However, the market also presents significant growth opportunities. The increasing focus on smart farming and precision agriculture opens new avenues for innovation and product development. Integrating AI and robotics in agricultural machinery is expected to revolutionize farming practices, creating demand for advanced hitch systems.

Government initiatives and subsidies promoting agricultural mechanization offer a substantial market boost. Countries like India and China are implementing policies to support farmers in adopting modern farming equipment, driving demand for Three Point Quick Hitches. Moreover, the trend towards sustainable farming practices creates opportunities for developing eco-friendly hitch systems that align with global efforts to reduce carbon footprints.

Key Factors When Selecting A Three Point Quick Hitch

Compatibility with Existing Equipment

When selecting a three-point quick hitch, the foremost consideration should be its compatibility with existing tractors and implements. Ensuring that the hitch can seamlessly integrate with your current machinery is critical for operational efficiency. Compatibility often depends on the hitch’s category, which is determined by the horsepower of the tractor. For instance, Category 1 hitches are suitable for tractors with 20-45 horsepower, while Category 2 hitches cater to tractors with 40-100 horsepower. Moreover, the hitch’s dimensions, such as the spacing and pin size, must match the implements’ specifications. This alignment ensures that the implements can be securely attached and detached without difficulty. Incompatibility could lead to operational delays, increased wear and tear, or even equipment damage, thus affecting productivity. Additionally, consider the hydraulic system compatibility if the quick hitch includes hydraulic top links or other hydraulic components. Ensure that the hydraulic connections and pressure ratings are appropriate for your tractor’s system to avoid any potential hydraulic failures or inefficiencies.

Build Quality and Materials

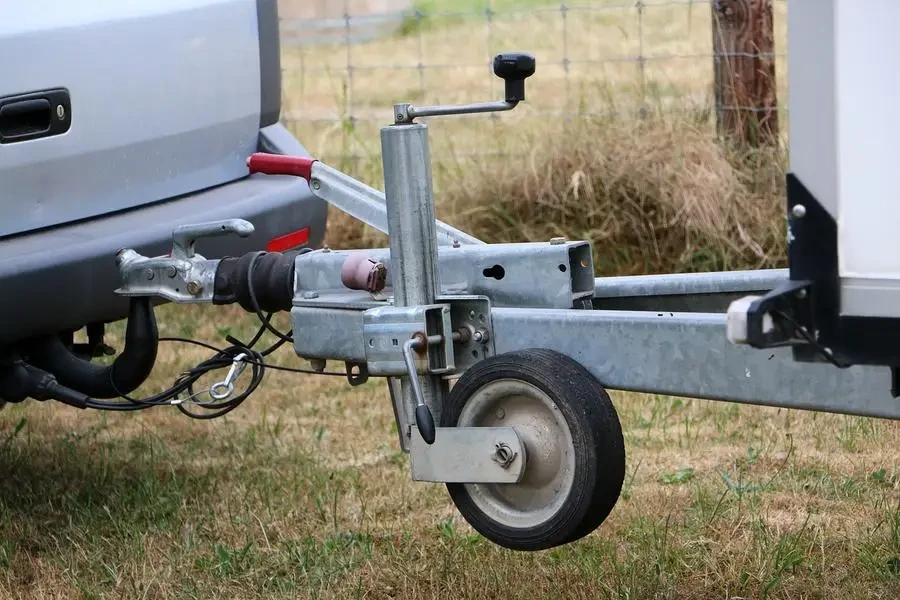

The build quality and materials of a three-point quick hitch significantly influence its durability and performance. High-quality materials such as hardened steel or alloy steel are preferred for their strength and resistance to wear and tear. Steel hitches are known for their robustness and ability to withstand heavy loads and harsh working conditions, which is essential for long-term use. The manufacturing process also plays a crucial role in the hitch’s durability. Processes such as precision forging and heat treatment enhance the material’s strength and resistance to deformation. Look for hitches that have undergone these processes to ensure they can handle the rigors of daily agricultural tasks. Furthermore, consider the hitch’s finish, such as powder coating or galvanization, which provides an additional layer of protection against corrosion and rust. This is particularly important if the hitch will be exposed to outdoor elements or corrosive substances, as it extends the lifespan of the equipment.

Ease of Use and Installation

The ease of use and installation is another critical factor when selecting a three-point quick hitch. A well-designed quick hitch should allow for easy attachment and detachment of implements without the need for additional tools or excessive manual labor. Features such as automatic locking mechanisms and adjustable top links can significantly simplify the process, saving time and reducing physical strain on the operator. Consider hitches with clear and straightforward installation instructions. Some hitches come with user-friendly manuals or even instructional videos that can guide you through the setup process. Additionally, the availability of quick-connect features, such as spring-loaded pins and quick-release levers, can further enhance the hitch’s usability. Furthermore, the hitch’s weight and maneuverability should be taken into account. A lightweight yet sturdy hitch is easier to handle and install, especially in tight spaces or when frequent changes between implements are required. Ergonomic design elements, such as comfortable handles and accessible adjustment points, also contribute to a more user-friendly experience.

Safety Standards and Certifications

Adherence to safety standards and certifications is paramount when selecting a three-point quick hitch. Ensuring that the hitch meets or exceeds industry safety standards, such as those set by the International Organization for Standardization (ISO) or the American Society of Agricultural and Biological Engineers (ASABE), provides assurance of its reliability and safety. Look for hitches that have been tested and certified for mechanical strength, durability, and safe operation. Certifications from recognized bodies indicate that the hitch has undergone rigorous testing and meets the necessary safety criteria. This is particularly important in preventing accidents and ensuring the safety of operators and bystanders during use. Additionally, consider hitches that include safety features such as lockable pins, safety chains, and reinforced attachment points. These features enhance the hitch’s stability and prevent accidental detachment of implements, which could lead to hazardous situations. Prioritizing safety-certified hitches helps mitigate risks and ensures compliance with regulatory requirements.

Price Range and Budget Considerations

Price range and budget considerations are essential when selecting a three-point quick hitch. The cost of a quick hitch can vary significantly based on factors such as build quality, materials, brand reputation, and additional features. It is crucial to balance cost with the desired level of quality and functionality to ensure value for money. While it may be tempting to opt for the cheapest option available, it is important to consider the long-term implications of such a decision. Low-cost hitches may compromise on materials and build quality, leading to frequent repairs or replacements, which can ultimately result in higher overall costs. Investing in a high-quality hitch, even if it comes with a higher initial price tag, can provide greater durability and reliability, reducing long-term expenses. Additionally, consider any available warranties or service agreements that come with the hitch. A comprehensive warranty can provide peace of mind and protect your investment in case of defects or malfunctions. Evaluate the cost-benefit ratio and choose a hitch that aligns with your budget while meeting your operational needs and quality expectations.

Understanding the Importance of Material Selection

Material selection plays a crucial role in determining the performance and longevity of a three-point quick hitch. Different materials offer varying levels of strength, corrosion resistance, and weight, all of which impact the hitch’s overall functionality and durability.

Steel and Alloy Steel

Steel and alloy steel are commonly used materials for three-point quick hitches due to their exceptional strength and durability. Steel hitches can withstand heavy loads and harsh working conditions, making them ideal for agricultural and industrial applications. Alloy steel, which includes additional elements such as chromium or nickel, offers enhanced strength and resistance to wear and corrosion. The choice between standard steel and alloy steel depends on the specific requirements of the application. For instance, alloy steel hitches are preferable in environments where the hitch is exposed to corrosive substances or extreme weather conditions. The added corrosion resistance ensures a longer lifespan and reduced maintenance needs.

Aluminum

Aluminum is another material option for three-point quick hitches, particularly valued for its lightweight properties. Aluminum hitches are easier to handle and install due to their reduced weight, which can be beneficial in applications where frequent changes between implements are required. However, aluminum is not as strong as steel and may not be suitable for heavy-duty tasks or environments with high mechanical stress. Despite its lower strength, aluminum offers good corrosion resistance, making it a suitable choice for applications where exposure to moisture or corrosive elements is a concern. Additionally, aluminum hitches are often more cost-effective than their steel counterparts, providing a budget-friendly option for lighter-duty applications.

Composite Materials

In recent years, composite materials have gained popularity in the manufacturing of three-point quick hitches. These materials combine different elements, such as fiberglass or carbon fiber, to create a product that offers a balance of strength, weight, and corrosion resistance. Composite hitches can provide the durability of steel while remaining lightweight like aluminum. The use of composite materials allows for innovative designs and improved performance characteristics. For example, composite hitches can be engineered to have higher impact resistance and flexibility, reducing the likelihood of damage under heavy loads. This material choice is particularly advantageous in applications where both strength and weight are critical factors.

Enhancing Efficiency with Advanced Features

Modern three-point quick hitches come equipped with advanced features that enhance efficiency and ease of use. These features are designed to streamline the attachment and detachment process, reduce manual labor, and improve overall operational productivity.

Hydraulic Top Links

Hydraulic top links are a valuable addition to three-point quick hitches, providing adjustable linkage that can be controlled from the tractor’s cab. This feature allows operators to easily adjust the angle and height of the attached implement without leaving their seat, saving time and effort. Hydraulic top links are particularly useful for tasks that require frequent adjustments, such as grading or plowing. The use of hydraulic top links also improves the precision and accuracy of implement positioning, leading to better results and reduced wear on both the hitch and the implement. This feature is especially beneficial in applications where consistent implement alignment is critical for optimal performance.

Automatic Locking Mechanisms

Automatic locking mechanisms simplify the process of securing implements to the hitch, eliminating the need for manual intervention. These mechanisms engage automatically when the implement is connected, ensuring a secure and reliable attachment. This feature reduces the risk of implements becoming detached during operation, enhancing safety and efficiency. Automatic locking mechanisms also save time during implement changes, allowing operators to quickly switch between tasks without the need for additional tools or adjustments. This increased efficiency can lead to higher productivity and reduced downtime, making it a valuable feature for busy agricultural operations.

Quick-Release Levers

Quick-release levers provide a convenient way to detach implements from the hitch with minimal effort. These levers are designed for easy access and operation, allowing operators to quickly release the implement without the need for manual tools or excessive force. Quick-release levers are particularly useful in applications where frequent implement changes are required, such as landscaping or construction. The use of quick-release levers also enhances safety by reducing the risk of accidental detachment during operation. This feature ensures that implements remain securely attached until intentionally released, providing peace of mind for operators and reducing the likelihood of equipment damage or accidents.

Conclusion

In summary, selecting the right three-point quick hitch involves careful consideration of compatibility, build quality, ease of use, safety standards, and budget. By prioritizing these factors and understanding the importance of material selection and advanced features, you can make an informed decision that enhances the efficiency and productivity of your operations. Investing in a high-quality quick hitch tailored to your specific needs ensures long-term reliability and optimal performance in various agricultural and industrial applications.