In 2024, the global market for desktop CNC mills reached a substantial $89.52 billion, driven by a surge in automation and precision manufacturing. As we move into 2025, the demand for these versatile machines is expected to grow even further, fueled by technological advancements and the increasing popularity of DIY manufacturing. This article provides an in-depth look at the key considerations for business buyers, including wholesalers, retailers, and purchasing professionals, when selecting desktop CNC mills.

Table of Contents:

1. Market Overview of Desktop CNC Mills

2. Detailed Analysis of the Desktop CNC Mills Market

3. Innovations and Trends in Desktop CNC Mills

4. Key Considerations When Selecting Desktop CNC Mills

5. Exploring the Types and Styles of Desktop CNC Mills

6. The Role of CNC Controllers in Desktop CNC Mills

7. Wrapping Up Insights on Desktop CNC Mills

Market Overview of Desktop CNC Mills

The global market for desktop CNC mills is experiencing robust growth, driven by the rising demand for precision manufacturing and the increasing adoption of automation technologies. According to Statista, the Tools & Machines market worldwide is projected to generate revenue of US$234.60bn in 2024, with desktop CNC mills playing a significant role. China leads the market with a revenue of US$78bn in 2024, highlighting the country’s dominance in manufacturing and industrial innovation. The market is anticipated to grow at a compound annual growth rate (CAGR) of 2.65% from 2024 to 2029, reflecting ongoing advancements and investments in the CNC technology sector.

Germany continues to be a key player, known for its precision engineering and high-quality manufacturing. The per capita income generated by the Tools & Machines market in Germany is US$45.68 in 2024, indicating a strong industrial base and consumer demand for advanced tools and machinery. The United States also holds a significant share, with the Tools & Machines market generating US$42.02bn in 2024 and an expected CAGR of 2.79% from 2024 to 2029. The focus on advanced manufacturing and the growing DIY culture contribute to the steady demand for desktop CNC mills in the U.S. market.

In New Zealand, the Tools & Machines market is projected to generate US$1.21bn in 2024, with a per capita revenue of US$229.00. The country’s commitment to environmental conservation is driving the demand for eco-friendly and sustainable tools, including desktop CNC mills. The market’s growth is influenced by various macroeconomic factors, such as global economic trends, national economic health, and fiscal policies. Favorable economic conditions and government incentives are expected to promote the adoption of CNC technology, further boosting market growth.

Detailed Analysis of the Desktop CNC Mills Market

Key Performance Benchmarks and Market Share Dynamics

Desktop CNC mills are evaluated based on several key performance benchmarks, including precision, speed, and ease of use. The accuracy of these machines is typically measured in microns, with high-end models achieving tolerances as low as 10 microns. Speed is another critical factor, with spindle speeds ranging from 10,000 to 30,000 RPM, enabling rapid material removal and efficient production cycles. Leading manufacturers such as Haas Automation, Tormach, and Carbide 3D dominate the market, leveraging their advanced technological capabilities and extensive distribution networks.

Economic Influences and Consumer Behavior Shifts

The economic landscape significantly impacts the desktop CNC mills market. Global economic stability and rising industrial investments drive the demand for CNC technology. Consumer behavior is shifting towards automation and precision manufacturing, with small businesses and hobbyists increasingly adopting desktop CNC mills for prototyping and small-scale production. The growing interest in DIY projects and the need for customizable solutions also contribute to the market’s expansion, as consumers seek versatile and user-friendly machines.

Seasonal Demand Patterns and Distribution Channel Preferences

Seasonal demand patterns in the desktop CNC mills market are influenced by industry cycles and educational institutions’ academic calendars. Peak demand often occurs during the start of the academic year, as educational institutions invest in new equipment for engineering and manufacturing programs. Distribution channel preferences vary, with online platforms gaining popularity due to their convenience and extensive product offerings. Traditional distribution channels, such as specialized machinery retailers, continue to play a crucial role, providing personalized customer service and technical support.

Innovations and Trends in Desktop CNC Mills

Recent Innovations and Product Lifecycle Stages

Recent innovations in desktop CNC mills include advancements in software integration, enhanced automation features, and the development of more compact and efficient designs. These innovations aim to improve usability, reduce setup times, and increase overall productivity. The product lifecycle of desktop CNC mills typically involves three stages: introduction, growth, and maturity. During the introduction stage, new models are launched with cutting-edge features. The growth stage sees widespread adoption and increasing sales, while the maturity stage involves market saturation and incremental improvements.

Digitalization and Social Trends

The digitalization of manufacturing processes has significantly impacted the desktop CNC mills market. The integration of IoT (Internet of Things) and cloud-based solutions allows for real-time monitoring and remote control of CNC machines, enhancing operational efficiency and reducing downtime. Social trends, such as the maker movement and the rise of small-scale manufacturing, are driving the demand for affordable and accessible CNC technology. Consumers are increasingly seeking machines that offer connectivity and smart features, reflecting the broader trend towards digital transformation in manufacturing.

Environmental Regulations and Customer Pain Points

Environmental regulations are shaping the development and adoption of desktop CNC mills, with manufacturers focusing on energy efficiency and sustainable practices. The use of recyclable materials and the reduction of waste are key considerations in the design and production of CNC machines. Customer pain points often include the complexity of machine setup and operation, the need for regular maintenance, and the initial investment cost. Addressing these challenges through user-friendly interfaces, comprehensive support services, and cost-effective solutions is essential for manufacturers to maintain a competitive advantage.

In conclusion, the desktop CNC mills market is poised for significant growth, driven by technological advancements, changing consumer preferences, and favorable economic conditions. Industry stakeholders must continue to innovate and adapt to evolving market dynamics to capitalize on the opportunities in this expanding sector.

Key Considerations When Selecting Desktop CNC Mills

When choosing a desktop CNC mill, it’s essential to consider several factors to ensure it meets your manufacturing needs. Here are some critical aspects to evaluate:

Technical Specifications

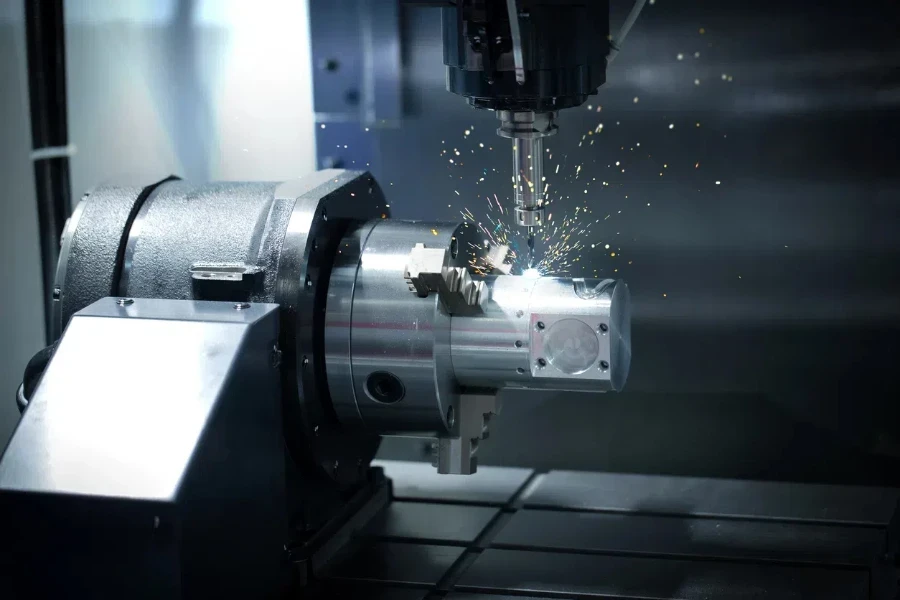

Technical specifications are crucial in selecting a desktop CNC mill. One primary specification is the number of axes the machine supports, typically ranging from three to five. A three-axis machine moves along the X, Y, and Z axes, suitable for simpler tasks. For more complex milling, a five-axis machine is preferable as it allows additional rotation and tilting, enabling intricate designs and undercuts.

Spindle speed and power are also vital. Spindle speeds range from a few thousand to over 25,000 RPM. Higher speeds are better for softer materials like wood and plastics, while tougher materials may need slower speeds but higher torque, requiring a powerful spindle motor. Additionally, consider the tool magazine’s capacity, especially for tasks needing frequent tool changes.

Performance and Functionality

The performance of a desktop CNC mill is often measured by its precision, speed, and repeatability. Precision is about the machine’s ability to maintain tight tolerances, critical for parts that need exact specifications, such as in aerospace or medical device manufacturing.

Speed is another key metric; faster machines allow higher throughput. However, speed should not compromise accuracy, so find a balance based on your application. Repeatability, or producing identical parts in successive runs, ensures consistent quality. Machines with advanced CNC controllers often offer better repeatability due to algorithms compensating for mechanical variances.

Build Quality and Materials

The build quality affects a CNC mill’s durability and performance. Machines made from high-grade materials like cast iron or steel offer excellent stability and vibration dampening, crucial for maintaining precision. Lighter materials, such as aluminum, may be used in cheaper models but can lack rigidity.

Quality components like linear guides, ball screws, and motors ensure smoother operation, reduced maintenance, and longer lifespan. Additionally, the design should allow easy maintenance, with replaceable or upgradeable components to extend the machine’s utility.

Software and Compatibility

Software compatibility is essential as it affects programming and operation ease. Most modern CNC mills work with CAD/CAM software, allowing easy integration into existing workflows. Importing designs directly from CAD software can reduce setup times and improve accuracy.

The CNC controller’s user interface also impacts usability. A well-designed interface with intuitive controls can boost productivity by reducing training needs. Features like touchscreens, graphical displays, and remote monitoring enhance the user experience. Compatibility with common file formats like G-code ensures the machine can interpret and execute complex designs.

Safety and Certifications

Safety is crucial when selecting industrial equipment, including desktop CNC mills. Machines should comply with safety standards and certifications like ISO and CE to meet industry regulations. Features such as emergency stop buttons, protective enclosures, and automatic shutdown mechanisms enhance operator safety.

Certifications indicate the machine’s quality and reliability, often reflecting rigorous testing and adherence to international standards. Investing in certified equipment can reduce liability risks and ensure compliance with workplace safety regulations.

Exploring the Types and Styles of Desktop CNC Mills

Desktop CNC mills come in various types and styles, each suited for different applications and materials. Understanding these variations helps in selecting the most suitable machine for specific needs.

Vertical vs. Horizontal Milling Machines

The main distinction is between vertical and horizontal configurations. Vertical milling machines, with vertically oriented spindles, are versatile and easy to use. They are ideal for precision tasks like engraving or intricate part manufacturing.

Horizontal milling machines have horizontally oriented spindles, better suited for heavier cutting tasks and quickly removing large material amounts. The choice depends on specific manufacturing requirements and the materials processed.

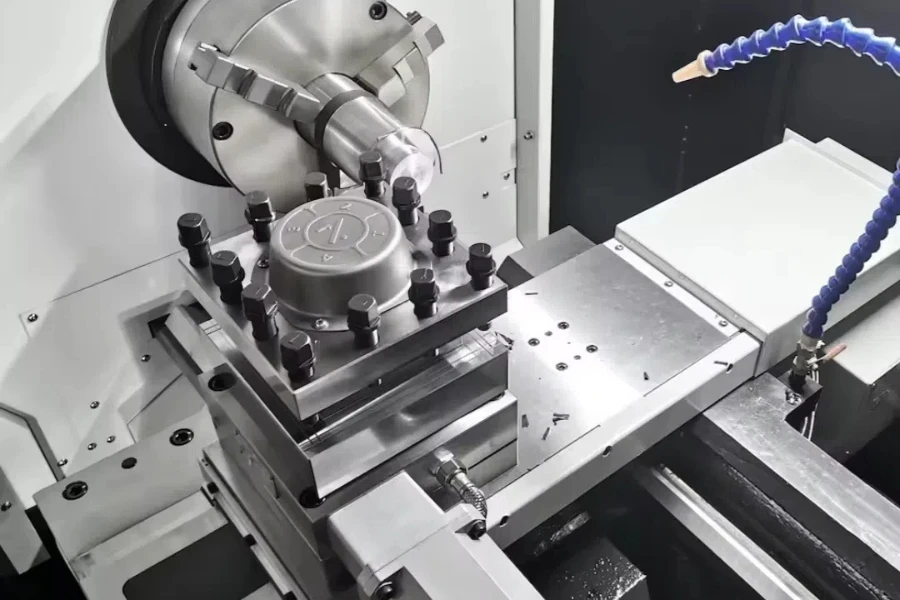

Gantry and Bed Mills

Gantry mills and bed mills offer unique advantages. Gantry mills have an overhead gantry moving the spindle along the X, Y, and Z axes, beneficial for large workpieces due to greater flexibility and range of motion.

Bed mills, with fixed spindles and movable tables, suit smaller, precise tasks. The fixed spindle design provides enhanced stability and precision, ideal for detailed work. When choosing between these, consider the size and complexity of the parts to be manufactured.

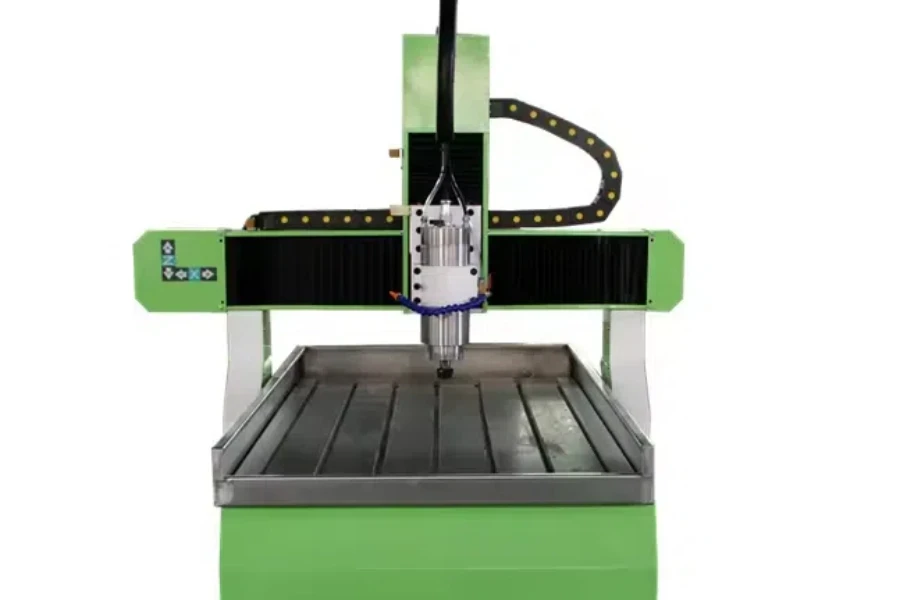

Compact and Portable Models

For space-constrained applications, compact and portable desktop CNC mills are viable solutions. Designed to fit on a desktop or small workbench, they are ideal for workshops with limited space. Despite their size, many compact models offer notable precision and functionality for prototyping and small-scale production.

Portable models are also useful for educational purposes or fieldwork, where mobility is needed. These machines typically operate on standard power supplies and can be easily transported, offering flexibility in various environments.

The Role of CNC Controllers in Desktop CNC Mills

CNC controllers are integral to desktop CNC mills, providing the interface between software and machine hardware. Understanding their capabilities and features is essential for optimizing machine performance.

Configuration and Features

CNC controllers come in various configurations: desktop, rack-mounted, and pendant types. Desktop controllers allow operators to manage machines nearby, offering convenience. Rack-mounted controllers are used in industrial settings for space efficiency, housing components in standard racks.

Features like alarms, event monitoring, and multi-program storage enhance functionality, offering insights into machine performance and issues. Advanced controllers may include self-diagnostic features, helping quickly identify and resolve problems, minimizing downtime.

Industrial Communication Protocols

The communication protocol determines a CNC controller’s compatibility with other systems. Common protocols include Ethernet, PROFIBUS, and CANbus, each offering advantages in speed, reliability, and network integration. Ethernet-based systems are popular for their widespread use and high-speed data transfer.

Choosing a controller with the right protocol enhances integration into existing workflows, allowing seamless data exchange and coordination with other equipment.

Language and Operation

The language and operation of a CNC controller are crucial for programming and executing tasks. Most controllers support G-code, a standard CNC programming language defining tool paths and operations. Some advanced controllers offer additional languages and features like conversational programming or auto-scaling, simplifying complex tasks.

The choice of controller language should match the operators’ expertise and task complexity. Controllers with user-friendly interfaces and comprehensive documentation can reduce the learning curve and improve efficiency.

Wrapping Up Insights on Desktop CNC Mills

Evaluating key factors like technical specifications, performance, build quality, software compatibility, and safety standards is vital when selecting a desktop CNC mill. Understanding different types and styles of mills, as well as the role of CNC controllers, can inform purchasing decisions and optimize manufacturing processes.