In 2025, indoor air quality has become a top priority for businesses across the globe. This article delves into the latest trends and key factors in HVAC filter selection, offering professional buyers invaluable insights into making informed decisions. From understanding filter types to evaluating energy efficiency and regulatory compliance, this guide provides comprehensive assistance to navigate the HVAC filter market efficiently.

Table of Contents:

– HVAC Filter Market Overview

– In-Depth Analysis of the HVAC Filter Market

– Key Factors When Selecting HVAC Filters

– Advanced Filtration Technologies

– Regulatory Compliance and Certifications

– Cost Considerations

– Summary

HVAC Filter Market Overview

The HVAC filter market has seen substantial growth, driven by increasing awareness of indoor air quality and stringent environmental regulations. The market size is projected to grow from USD 29.50 billion in 2024 to USD 48.87 billion by 2030, at a CAGR of 8.59%. This expansion is fueled by the rising demand for efficient air purification systems in commercial, industrial, and residential sectors. The market is segmented by end-user into commercial, industrial, and residential applications, each contributing significantly to overall market growth.

APAC is anticipated to lead due to rapid industrialization, urbanization, and increasing automotive production. North America and Europe also hold substantial shares owing to stringent government regulations on air quality and well-established commercial sectors. The Middle East and Africa, along with South America, are expected to show moderate growth driven by increasing urbanization and construction activities.

Key players in the market include American Air Filter Co. Inc., Camfil AB, Carrier Global Corp., and Cummins Inc. These companies focus on innovations and strategic acquisitions to strengthen their market positions. For instance, Filtration Group’s acquisition of Universal Air Filter and K&N Engineering’s introduction of reusable high-performance air filters highlight the industry’s trend towards sustainable and efficient filtration solutions.

In-Depth Analysis of the HVAC Filter Market

The HVAC filter market is dynamic, with evolving consumer preferences, technological advancements, and regulatory influences. Growth is driven by benchmarks such as efficiency, longevity, and cost-effectiveness of filters. High-efficiency particulate air (HEPA) filters and activated carbon filters are popular due to their superior filtration capabilities. The market is also shifting towards pleated filters, which ensure better air purification and longer service life.

Economic influences like rising disposable incomes and increased spending on healthcare and wellness are boosting demand for high-quality HVAC filters. Growing concerns over indoor air quality (IAQ) in buildings have led to the adoption of advanced filtration systems in both residential and commercial sectors, especially in urban areas with higher pollution levels.

Distribution channels for HVAC filters are diversified, with significant presence in both online and offline platforms. The online segment is growing rapidly due to purchasing convenience and product variety. Offline channels, including specialty stores and direct sales, continue to hold a substantial share due to personalized services and immediate product availability.

Recent innovations in the HVAC filter market include the development of smart filters equipped with sensors for real-time air quality monitoring. These filters can adjust their performance based on detected air quality, ensuring optimal filtration efficiency. Additionally, integrating IoT and AI technologies in HVAC systems is enabling predictive maintenance, reducing operational costs, and enhancing system performance.

The product lifecycle of HVAC filters varies, with disposable filters typically having a shorter lifespan compared to reusable ones. There is a growing preference for washable and reusable filters, driven by environmental sustainability concerns and long-term cost savings. This shift is supported by advancements in filter materials, such as nanofibers and graphene, offering enhanced durability and filtration efficiency.

Customer pain points in the HVAC filter market include high installation and maintenance costs, which can be a barrier to adoption for some consumers. To address this, manufacturers are developing cost-effective solutions without compromising performance. Brand positioning strategies emphasize quality, reliability, and sustainability, with companies differentiating themselves through innovative products and superior customer service.

Niche markets within the HVAC filter industry include specialized filters for applications such as data centers, cleanrooms, and healthcare facilities. These segments require high-performance filters to maintain stringent air quality standards, presenting lucrative opportunities for manufacturers. Investments in green building construction and the emphasis on energy efficiency are also driving demand for advanced HVAC filters.

Key Factors When Selecting HVAC Filters

Types of HVAC Filters

HVAC filters come in various types, each with distinct features and applications. The most common types include mechanical, electrostatic, and electronic filters. Mechanical filters, such as fiberglass and pleated filters, capture larger particles like dust and lint. Electrostatic filters use static electricity to trap smaller particles and are often washable and reusable. Electronic filters, including ionizers and electrostatic precipitators, use electrical charges to remove particles but can be more expensive and require regular maintenance.

Material and Build Quality

The material and build quality of HVAC filters significantly impact their performance and longevity. Common materials include fiberglass, polyester, and pleated paper. Fiberglass filters are inexpensive and suitable for basic filtration needs, while polyester and pleated paper filters offer higher efficiency and durability. High-quality materials ensure that the filter maintains its integrity and effectiveness over time, reducing the need for frequent replacements.

MERV Rating

The Minimum Efficiency Reporting Value (MERV) rating is a critical factor in determining the effectiveness of an HVAC filter. MERV ratings range from 1 to 20, with higher ratings indicating better filtration efficiency. For residential use, filters with a MERV rating between 8 and 13 are typically sufficient, effectively capturing common allergens and particles. For commercial or industrial applications, higher MERV ratings may be necessary to meet specific air quality requirements.

Energy Efficiency

Energy efficiency is a crucial consideration for HVAC filters, as higher efficiency can lead to significant cost savings over time. Filters with lower pressure drops allow the HVAC system to operate more efficiently, reducing energy consumption. High-efficiency filters, such as HEPA filters, may have higher initial costs but can result in long-term savings by improving system performance and reducing energy bills.

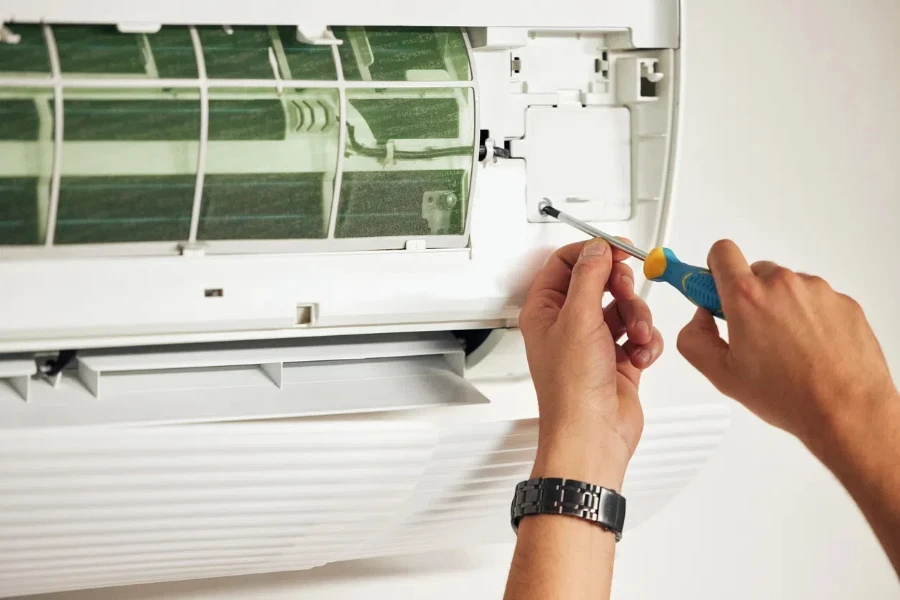

Compatibility and Ease of Installation

Ensuring compatibility with existing HVAC systems is essential when selecting filters. Filters come in various sizes and configurations, so it is important to choose one that fits the specific dimensions of the system. Additionally, ease of installation is a key factor, as filters that are difficult to install can lead to improper fitting and reduced efficiency. Look for filters with clear installation instructions and features like gaskets or frames that ensure a secure fit.

Advanced Filtration Technologies

HEPA Filters

High-Efficiency Particulate Air (HEPA) filters are renowned for their ability to capture 99.97% of particles as small as 0.3 microns. These filters are commonly used in environments requiring stringent air quality standards, such as hospitals and cleanrooms. HEPA filters are constructed with densely packed fibers that create a maze for particles to navigate, ensuring high capture efficiency. Despite their higher cost and pressure drop, HEPA filters are invaluable for critical applications where air purity is paramount.

UV Light Filters

Ultraviolet (UV) light filters use UV-C light to neutralize biological contaminants like bacteria, viruses, and mold spores. These filters are often integrated with traditional HVAC filters to enhance their effectiveness. UV light filters are particularly beneficial in healthcare settings and facilities with high occupant density, as they help maintain a sterile environment. Regular maintenance and bulb replacement are necessary to ensure continuous efficacy.

Activated Carbon Filters

Activated carbon filters remove gaseous pollutants and odors from the air. These filters use a bed of activated carbon to adsorb volatile organic compounds (VOCs), smoke, and other chemicals. Activated carbon filters are commonly used in environments where air quality is compromised by chemical emissions or strong odors, such as laboratories and industrial facilities. They are often combined with particulate filters to provide comprehensive air purification.

Regulatory Compliance and Certifications

Industry Standards

HVAC filters must comply with various industry standards and regulations to ensure safety and performance. Standards such as ASHRAE 52.2 and ISO 16890 provide guidelines for testing and rating air filter efficiency. Compliance with these standards ensures that the filters meet minimum performance criteria and can effectively improve indoor air quality. Manufacturers should provide documentation of compliance with relevant standards.

Environmental Certifications

Environmental certifications, such as ENERGY STAR and LEED, indicate that HVAC filters meet certain sustainability criteria. These certifications can be important for businesses looking to reduce their environmental impact and achieve green building certifications. Filters with environmental certifications are typically designed to optimize energy efficiency and reduce waste, contributing to overall sustainability goals.

Health and Safety Certifications

Health and safety certifications, such as those from the National Institute for Occupational Safety and Health (NIOSH) or Underwriters Laboratories (UL), ensure that HVAC filters meet stringent health and safety requirements. These certifications are particularly important in environments where air quality directly impacts occupant health, such as healthcare facilities and schools. Certified filters provide assurance that they will effectively reduce airborne contaminants and contribute to a healthier indoor environment.

Cost Considerations

Initial Purchase Price

The initial purchase price of HVAC filters can vary widely depending on the type, material, and efficiency rating. While lower-cost filters may be appealing for budget-conscious buyers, it is important to consider the long-term value. High-quality filters with higher efficiency ratings may have a higher upfront cost but can offer better performance and longevity, ultimately providing better value for money.

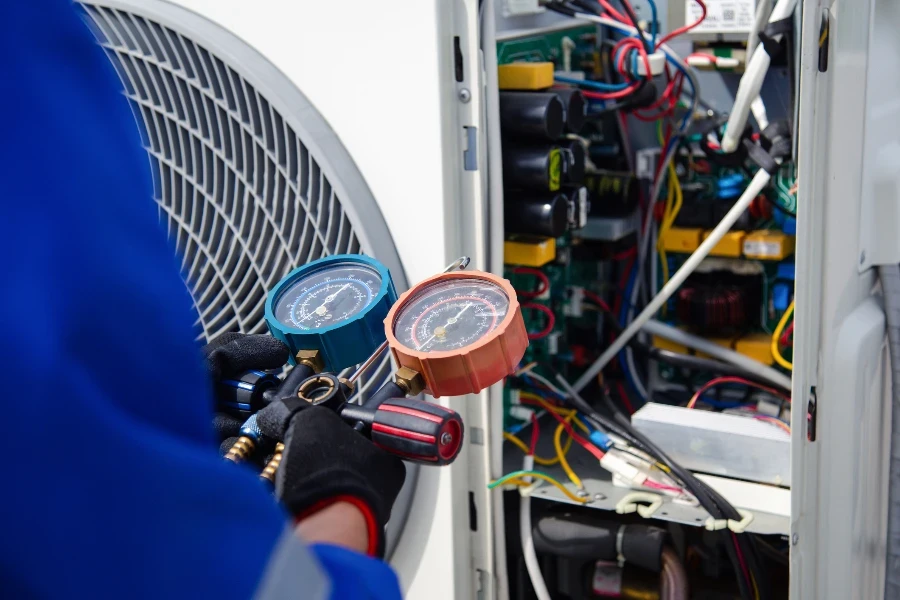

Maintenance and Replacement Costs

Maintenance and replacement costs are significant factors in the total cost of ownership for HVAC filters. Filters that require frequent replacement or extensive maintenance can become costly over time. Opting for filters with longer lifespans and lower maintenance requirements can reduce ongoing expenses. Additionally, washable and reusable filters can offer cost savings by reducing the need for frequent replacements.

Energy Savings

Energy savings are a critical consideration when evaluating the cost of HVAC filters. High-efficiency filters that reduce the pressure drop across the HVAC system can lead to significant energy savings. Over time, these savings can offset the higher initial purchase price of premium filters. Energy-efficient filters not only reduce operating costs but also contribute to a more sustainable and environmentally friendly building operation.

Summary

In summary, selecting the right HVAC filter involves evaluating key factors such as filter type, material quality, MERV rating, energy efficiency, and compatibility with existing systems. Advanced filtration technologies like HEPA, UV light, and activated carbon filters offer enhanced air purification for specialized applications. Compliance with industry standards and certifications ensures safety and performance, while cost considerations encompass initial purchase price, maintenance, and energy savings. By carefully considering these factors, buyers can choose HVAC filters that meet their specific needs and contribute to improved indoor air quality and system efficiency.