In 2024, the desktop milling machine market is witnessing a surge in demand, driven by technological advancements and a growing emphasis on precision manufacturing. As we look towards 2025, the integration of smart technologies and sustainable practices is set to redefine product selection for business buyers globally. Understanding these trends is crucial for wholesalers, retailers, and purchasing professionals aiming to stay competitive in the evolving market landscape.

Table of Contents:

Desktop Milling Machine Market: A Global Overview

In-depth Analysis of Desktop Milling Machine Market Dynamics

Key Considerations for Selecting a Desktop Milling Machine

Exploring the Latest Technology Features in Desktop Milling Machines

Evaluating the Cost and Budget Considerations for Desktop Milling Machines

Assessing the Safety and Maintenance Requirements of Desktop Milling Machines

Wrapping Up

Desktop Milling Machine Market: A Global Overview

The global tools and machines market, which includes desktop milling machines, is set to generate USD 234.60 billion in revenue by 2024. This market is projected to grow at a compound annual growth rate (CAGR) of 2.65% from 2024 to 2029. China leads this market with an estimated revenue of USD 78 billion in 2024, underscoring its significant global influence. The per capita revenue is expected to be USD 30.27 in 2024, reflecting widespread demand across various regions.

Germany, renowned for its precision engineering and high-quality manufacturing, continues to excel in the tools and machines market. The country’s emphasis on innovation and precision drives its success in this sector. Meanwhile, the United States is seeing increased demand for high-tech power tools and machinery, fueled by a growing DIY culture and the need for advanced manufacturing equipment. This trend is evident in the US’s projected revenue of USD 42.02 billion in 2024, with a CAGR of 2.79% from 2024 to 2029.

In contrast, the UK market is valued at USD 1.93 billion in 2024, with an anticipated annual growth rate of 3.12% from 2024 to 2029. The UK’s market is heavily influenced by its strong DIY culture and rising demand for home improvement products. These regional market dynamics highlight the diverse factors shaping the global tools and machines market, including cultural influences, technological advancements, and economic conditions.

In-depth Analysis of Desktop Milling Machine Market Dynamics

Desktop milling machines occupy a niche within the broader tools and machines market, known for their precision, versatility, and accessibility. Key performance indicators for these machines include spindle speed, feed rate, and material handling capabilities, essential for applications from prototyping to small-scale manufacturing. The market is shifting towards digitalization, with smart technology integration becoming more common. This includes features like CNC (Computer Numerical Control) capabilities and IoT (Internet of Things) connectivity, which enhance operational efficiency and precision.

Economic factors, such as global trends and national fiscal policies, significantly influence market dynamics. Countries with stable economies and favorable tax policies typically have a robust market for desktop milling machines due to higher consumer spending power. Additionally, government initiatives promoting advanced manufacturing technologies and infrastructure investments can boost demand for these machines. However, economic downturns and financial instability can impede market growth as consumers prioritize essential expenses over non-essential purchases like desktop milling machines.

Consumer behavior is evolving, with a growing preference for sustainable and eco-friendly machines. This trend is driven by increased awareness of environmental impact and a desire for more efficient solutions. The market is seeing innovations such as energy-efficient motors and the use of recycled materials in machine construction. Furthermore, the product lifecycle of desktop milling machines is being extended through modular designs and upgradeable components, meeting the demand for long-lasting and adaptable solutions. As the market evolves, companies must focus on quality, technological innovation, and customer support to maintain a competitive edge.

Key Considerations for Selecting a Desktop Milling Machine

When choosing a desktop milling machine, it’s important to consider several key factors to ensure it meets your specific needs. These include the machine’s type, performance specifications, design features, and potential for future upgrades. Understanding these elements will help you make an informed decision that aligns with your operational requirements and budget.

1. Types of Desktop Milling Machines

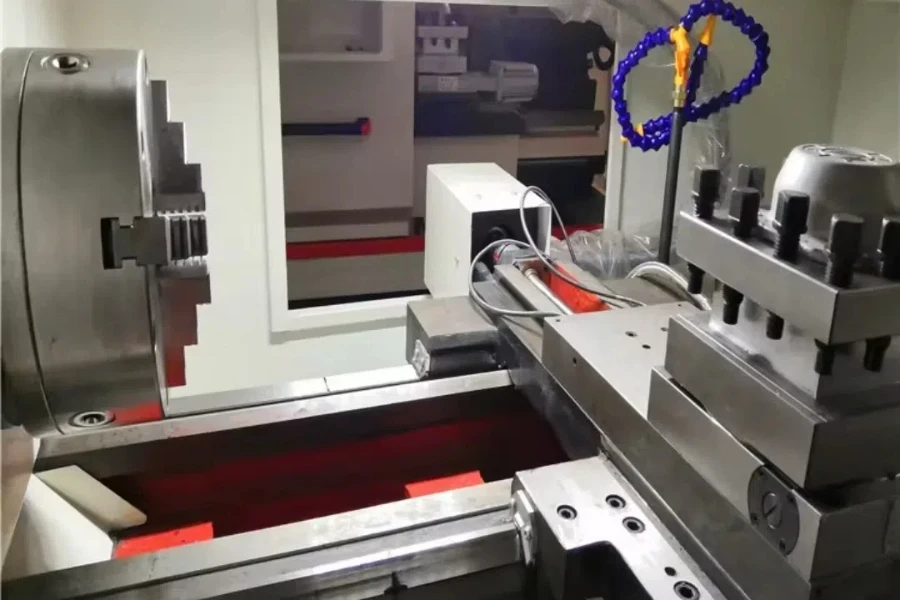

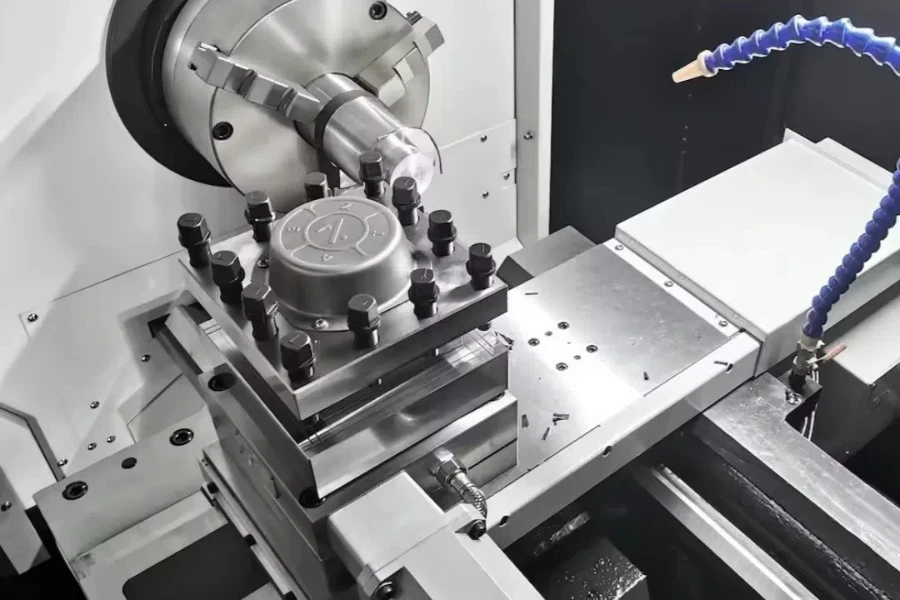

Desktop milling machines come in various types, each suited for different applications. Vertical milling machines (VMC) are popular for their versatility and ease of use, featuring a vertical spindle and an X-Y table, ideal for precision work. Horizontal milling machines (HMC) have a horizontal spindle and are better for heavy-duty tasks requiring significant material removal. Universal milling machines offer the flexibility of both vertical and horizontal milling, making them versatile for diverse applications. Gantry milling machines are designed for large workpieces and offer advanced capabilities like five-axis and six-axis milling, essential for complex geometries.

2. Performance Specifications

Performance specifications are crucial when evaluating a desktop milling machine. Key specifications include spindle speed, drive power, and the number of axes. Spindle speed, measured in revolutions per minute (RPM), determines the machine’s efficiency in cutting materials. Drive power, typically rated in horsepower or kilowatts, indicates the machine’s capability to handle various materials. The number of axes, such as three, four, or five, affects the machine’s ability to perform complex cuts and shapes. Machines with more axes offer greater flexibility and precision, vital for intricate designs.

3. Design and Aesthetics

The design and aesthetics of a desktop milling machine can impact its usability and integration into your workspace. Compact machines are ideal for small workshops or educational settings where space is limited. Aesthetically pleasing machines with a modern design can enhance the professional appearance of your workspace. Ergonomic features such as user-friendly interfaces and adjustable components can improve operator comfort and efficiency. Machines with enclosures or dust collection systems help maintain a clean working environment, crucial for precision work.

4. Technical Specifications and Features

Technical specifications and features significantly impact a desktop milling machine’s functionality. Machines equipped with computer-aided design (CAD) and computer-aided manufacturing (CAM) software offer enhanced capabilities for designing and executing complex projects. Cooling systems prevent overheating during prolonged use, ensuring the machine’s longevity and performance. Machines with digital readouts provide precise measurements, critical for achieving high accuracy in milling operations. On-site calibration services offered by suppliers can further enhance the machine’s precision and reliability.

5. Compatibility and Upgrade Potential

Compatibility with future upgrades is an important consideration for desktop milling machines. Machines that support a wide range of tooling options, such as CAT, BT, or HSK, offer greater flexibility for various applications. The ability to integrate with other devices and systems, such as CNC controllers or automation equipment, can enhance the machine’s functionality and efficiency. Machines with modular designs allow for easy upgrades and expansions, ensuring they remain relevant as technology advances. Considering the machine’s compatibility with future upgrades can help maximize your investment and extend its lifespan.

Exploring the Latest Technology Features in Desktop Milling Machines

The desktop milling machine industry is continuously evolving, with new technology features enhancing performance and usability. One significant advancement is the integration of CNC technology, allowing for precise control and automation of milling operations. CNC milling machines use G-codes to execute complex designs, reducing manual intervention and increasing productivity. This technology is particularly beneficial for industries requiring high precision and repeatability, such as aerospace and automotive manufacturing.

Another notable feature is the inclusion of advanced software packages for CAD and CAM. These solutions enable users to design intricate parts and simulate milling operations before production, reducing errors and material waste, leading to cost savings and improved efficiency. Additionally, some machines offer cloud-based software solutions, allowing for remote monitoring and control of milling operations, useful for businesses with multiple locations or those needing real-time data access.

The development of smart sensors and IoT connectivity is also transforming desktop milling machines. Smart sensors provide real-time data on machine performance, such as spindle speed, temperature, and vibration levels. This data can optimize milling operations and prevent potential issues. IoT connectivity allows machines to communicate with other devices and systems, enabling seamless integration into smart manufacturing environments. These technological advancements are driving the industry towards more efficient and intelligent milling solutions.

Evaluating the Cost and Budget Considerations for Desktop Milling Machines

When purchasing a desktop milling machine, cost and budget considerations are paramount. Prices can vary significantly based on type, specifications, and features. Entry-level machines are typically more affordable and suitable for hobbyists or educational purposes, offering basic functionality for simple projects. However, they may lack the advanced features and precision required for professional applications.

Mid-range machines offer a balance between cost and performance, making them suitable for small to medium-sized businesses. These machines often include CNC capabilities, advanced software packages, and enhanced precision, ideal for businesses requiring reliable performance without the high cost of industrial-grade machines. Investing in a mid-range machine can provide a good return on investment, especially for businesses looking to expand their capabilities.

High-end machines are designed for industrial applications and come with a higher price tag. These machines offer the latest technology features, such as multi-axis capabilities, high spindle speeds, and robust construction, suitable for industries demanding high precision and efficiency, like aerospace and medical device manufacturing. While the initial investment may be substantial, the long-term benefits of increased productivity and reduced downtime can justify the cost.

Assessing the Safety and Maintenance Requirements of Desktop Milling Machines

Safety and maintenance are critical aspects of owning and operating a desktop milling machine. Ensuring the machine meets industry safety standards and certifications is essential to protect operators and prevent accidents. Machines with safety features such as emergency stop buttons, protective enclosures, and automatic shut-off systems can enhance workplace safety. Additionally, providing proper training for operators on safe machine handling and operation is crucial to minimize risks.

Regular maintenance is necessary to keep the machine in optimal condition and extend its lifespan. Maintenance tasks may include cleaning, lubrication, and inspection of components such as spindles, bearings, and drive systems. Some machines come with maintenance schedules and alerts, making it easier to track necessary tasks. Suppliers offering maintenance services and support can be valuable partners in ensuring the machine’s reliability and performance.

Understanding the machine’s warranty and after-sales service options is also important. A comprehensive warranty can provide peace of mind and protect against unexpected repair costs. After-sales services, such as technical support and spare parts availability, can ensure the machine remains operational and efficient. Evaluating these factors can help you make an informed decision and maximize the value of your investment.

Wrapping Up

Selecting the right desktop milling machine involves considering various factors such as type, performance, design, and cost. By understanding these elements, you can make an informed decision that meets your specific needs and budget.