In 2024, the food sealer machine market is booming, with a projected value of USD 2.5 billion. As we move into 2025, technological advancements like IoT and AI integration are set to revolutionize the industry, making these machines indispensable for business buyers looking to enhance efficiency and sustainability.

Table of Contents:

1. A Comprehensive Market Overview of Food Sealer Machines

2. In-depth Analysis of the Food Sealer Machine Market Dynamics

3. Key Factors When Selecting a Food Sealer Machine

4. Advanced Features and Technology in Food Sealer Machines

5. Maintenance and Durability

6. Cost and Budget Considerations

7. Conclusion

A Comprehensive Market Overview of Food Sealer Machines

The global market for food sealer machines is set for significant growth, driven by the increasing demand for food preservation and waste reduction solutions. By 2024, the market is expected to reach approximately USD 2.5 billion, with a compound annual growth rate (CAGR) of around 5.6% from 2024 to 2029. This growth is largely due to heightened awareness of food safety and the benefits of vacuum sealing, especially in North America and Europe, where consumer preferences are shifting towards sustainable and efficient food storage methods.

North America leads the market with an estimated revenue of USD 1.1 billion in 2024, followed by Europe at USD 800 million. The Asia-Pacific region is anticipated to experience the highest growth rate, driven by increasing urbanization and disposable incomes, which fuel the demand for advanced kitchen appliances. Technological advancements in food sealer machines, such as smart sealing and automation, are also contributing to market expansion. The integration of IoT and AI technologies into food sealers is expected to revolutionize the market by 2025, enhancing user convenience and operational efficiency.

Key players in the market include prominent brands like FoodSaver, Hamilton Beach, and Nesco, which dominate with their innovative product offerings. The competitive landscape is characterized by continuous product development and strategic partnerships aimed at expanding market reach. The rising trend of at-home cooking and meal prepping, accelerated by the global pandemic, has further boosted the demand for food sealer machines, making them an essential household appliance.

In-depth Analysis of the Food Sealer Machine Market Dynamics

The performance benchmarks for food sealer machines focus on sealing efficiency, ease of use, and durability. Consumers increasingly seek machines that offer quick and reliable sealing capabilities, with minimal air leakage to ensure prolonged food freshness. Market dynamics indicate a shift towards more compact and user-friendly designs, catering to the growing urban population living in smaller spaces. Economic factors such as rising food prices and the emphasis on reducing food waste are also driving the adoption of food sealer machines.

Consumer behavior is evolving with a preference for sustainable and eco-friendly products, prompting manufacturers to innovate in biodegradable and reusable sealing materials. Seasonal demand patterns are evident, with sales peaking during holiday seasons and harvest times when food preservation needs are highest. Distribution channels are diversifying, with e-commerce platforms gaining popularity due to their convenience and wider product availability, complementing traditional retail outlets.

Recent innovations in the market include the introduction of multi-functional food sealers that can handle various types of packaging, from plastic bags to containers. Digitalization is playing a crucial role, with smart sealers offering connectivity features that allow users to monitor and control the sealing process via smartphone apps. Environmental regulations are influencing product designs, pushing companies to adopt greener technologies and materials, aligning with the global push towards sustainability.

Key Factors When Selecting a Food Sealer Machine

When choosing a food sealer machine, it’s important to consider several key factors to ensure it meets your needs. These include the type of sealer, performance, functionality, design, and technical specifications. Let’s explore these aspects in detail.

Types of Food Sealer Machines

Food sealer machines come in various types, each suited for different uses. The main types are vacuum sealers, chamber vacuum sealers, and external vacuum sealers.

Vacuum Sealers

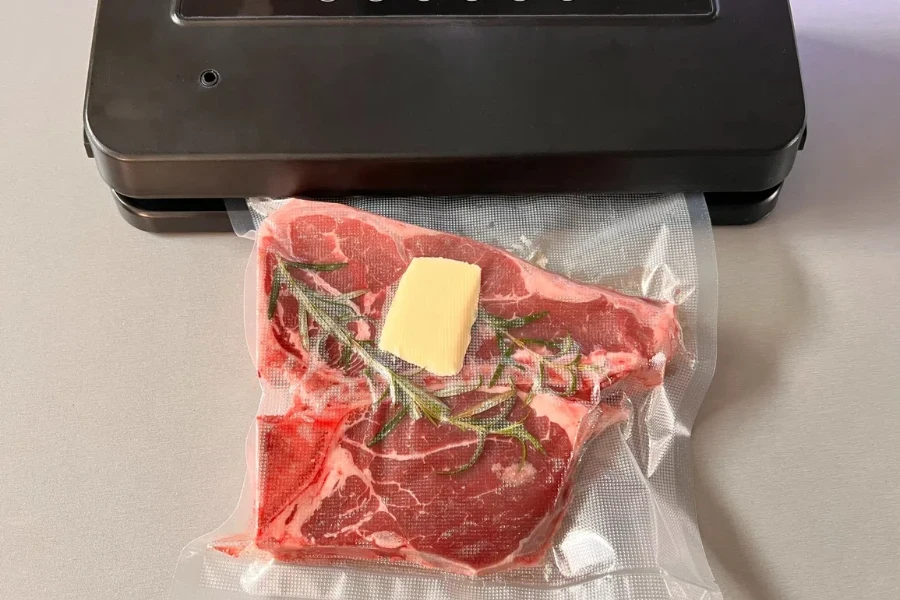

Vacuum sealers are popular for extending food shelf life by removing air from packaging. Suitable for both home and commercial use, they work by placing food in a plastic bag, extracting the air, and sealing the bag. This process helps preserve the food’s freshness and flavor.

Chamber Vacuum Sealers

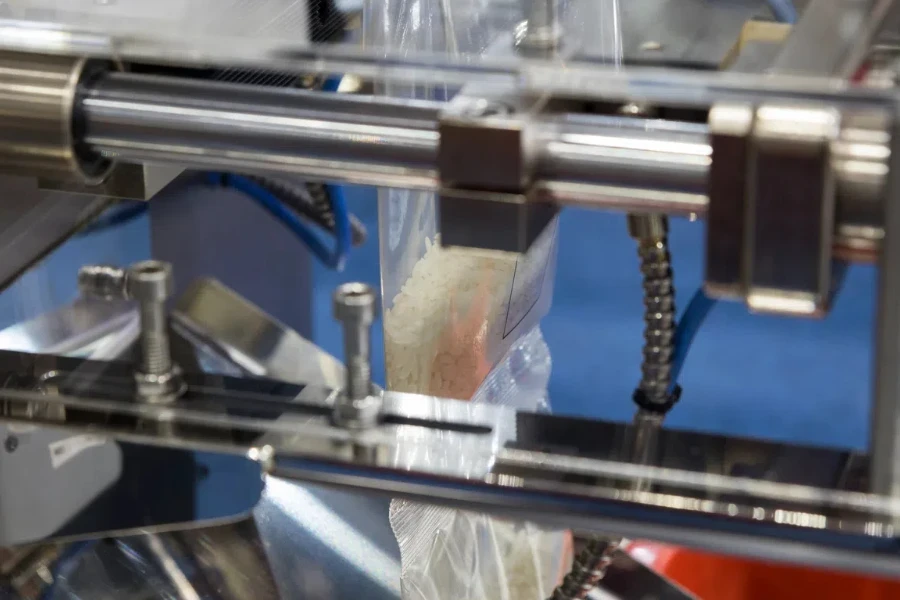

Chamber vacuum sealers are more advanced and typically used in commercial settings. They place the entire bag inside a chamber, remove the air, and seal the bag. These sealers efficiently handle liquids and moist foods better than external vacuum sealers and can seal multiple bags at once.

External Vacuum Sealers

External vacuum sealers are compact and ideal for home use. They work by placing the open end of the bag into the machine, which then removes the air and seals the bag. Generally less expensive than chamber vacuum sealers, they are perfect for dry foods and smaller quantities.

Performance and Functionality

Performance and functionality are crucial in determining how well a food sealer machine will meet your needs.

Sealing Speed

Sealing speed is important, especially in commercial settings where time is critical. High-end machines can seal multiple bags per minute, boosting productivity. For home use, a slower speed may suffice, but businesses need faster machines.

Sealing Strength

A strong seal ensures food remains fresh and uncontaminated. Machines with adjustable sealing strength are advantageous, allowing customization based on the food type.

Ease of Use

Ease of use is vital, particularly for home users. Machines with intuitive controls, clear instructions, and easy maintenance are preferred. Features like automatic sealing, one-touch operation, and easy-to-clean components enhance user experience.

Design and Aesthetics

The design and aesthetics of a food sealer machine affect its usability and appeal. While functionality is key, a well-designed machine can improve the overall experience.

Compactness

For home use, a compact design saves counter space and is easier to store. Commercial machines, though larger, should maximize space efficiency in busy kitchens.

Material and Build Quality

The materials used in the machine’s construction affect its durability. Stainless steel is popular for commercial machines due to its robustness. For home use, high-quality plastic or a mix of plastic and metal offers a balance of durability and affordability.

Aesthetic Appeal

While not critical, aesthetic appeal matters, especially for home users. A sleek, modern design can complement kitchen decor and make the machine more appealing.

Technical Specifications

Understanding a food sealer machine’s technical specifications ensures it meets your needs. Key specifications include power, vacuum strength, and bag compatibility.

Power

Measured in watts, the machine’s power affects performance and efficiency. Higher wattage machines handle demanding tasks and seal faster. For commercial use, higher power ratings are recommended.

Vacuum Strength

Measured in inches of mercury (inHg), vacuum strength indicates the machine’s air removal capability. Higher vacuum strength results in better air removal and longer food shelf life. Machines with adjustable vacuum strength offer flexibility for different foods.

Bag Compatibility

Bag compatibility is important. Some machines work with specific brands or types, while others offer more flexibility. Ensuring compatibility with readily available and affordable bags saves time and money.

Advanced Features and Technology in Food Sealer Machines

As technology advances, food sealer machines offer more sophisticated features that enhance functionality and ease of use.

Smart Sealing Technology

Smart sealing technology, found in high-end machines, automatically adjusts sealing parameters based on the food type. It detects moisture levels and adjusts vacuum strength and sealing time, ensuring optimal sealing and extended shelf life.

Integrated Scales

Some advanced machines have integrated scales for weighing food before sealing. This feature aids portion control and meal planning, ensuring bags aren’t overfilled, which can compromise the seal.

Wi-Fi Connectivity

Wi-Fi connectivity is increasingly common in modern machines, allowing remote control via smartphone apps. Users can start or stop sealing, monitor status, and receive notifications, adding convenience and flexibility.

Maintenance and Durability

Maintenance and durability are important, especially for commercial users relying on the machine daily.

Maintenance Requirements

Regular maintenance keeps the machine in good condition. Machines with easy-to-clean components and accessible parts are preferred. Some have self-cleaning features that simplify maintenance. Following the manufacturer’s maintenance guidelines ensures longevity.

Durability

Durability depends on material quality and construction. Machines made from high-quality materials like stainless steel are more durable. Consider the warranty and after-sales service provided by the manufacturer for peace of mind and investment protection.

Replacement Parts

Availability of replacement parts is crucial. Machines with readily available and affordable parts are easier to maintain and repair, extending lifespan and reducing downtime.

Cost and Budget Considerations

The cost of a food sealer machine varies widely based on features, performance, and brand. Consider your budget and the machine’s value.

Price Range

Food sealer machines range from affordable home models to high-end commercial machines. Home models typically cost $50 to $200, while commercial machines can be several hundred to several thousand dollars. Balance your budget with the features and performance needed.

Value for Money

Consider value for money when evaluating cost. A machine with advanced features, high performance, and good durability may have a higher upfront cost but offers better long-term value. Also, consider the cost of consumables like bags and replacement parts.

Financing Options

For commercial users, financing options may spread the machine’s cost over time, easing investment in a high-quality machine without a large upfront expense. Explore different financing options to fit your budget and financial situation.

Conclusion

Selecting the right food sealer machine involves considering factors like the type of sealer, performance, functionality, design, technical specifications, advanced features, maintenance, durability, and cost. By evaluating these factors, you can choose a machine that meets your needs and offers the best value for your investment.