The freeze drying equipment market continues to expand, driven by the latest advancements and the rising demand for long-lasting products. In this article, we delve into an in-depth analysis of the current market trends, technological innovations, and key performance benchmarks. Professional buyers will find valuable insights to make informed decisions, ensuring optimal investment in high-quality freeze drying equipment.

Table of Contents:

– Freeze Drying Equipment Market Overview

– In-depth Analysis of the Freeze Drying Equipment Market

– Key Factors When Selecting Freeze Drying Equipment

– Energy Efficiency and Sustainability

– Wrapping Up the Discussion

Freeze Drying Equipment Market Overview

The freeze drying equipment market has witnessed substantial growth due to the increasing demand for preserving food and pharmaceutical products. In 2024, the global market size for freeze drying equipment was estimated at USD 5.76 billion, projected to reach USD 7.83 billion by 2030, growing at a CAGR of 5.15%. This growth is driven by the need for long shelf-life products, advancements in freeze drying technology, and the expansion of the food and pharmaceutical industries.

The Americas, especially the United States and Canada, have shown strong demand due to large-scale production of processed food and pharmaceuticals. The European market, influenced by stringent food safety regulations, also demonstrates significant growth. The Asia-Pacific region, led by China, India, and Japan, is experiencing rapid growth due to urbanization, higher disposable incomes, and investments in food processing infrastructure.

Key players in the market include GEA Group, SPX FLOW Inc., and Yamato Scientific Co., Ltd., focusing on technological innovations to enhance energy efficiency and automation in freeze drying processes. The market is segmented by equipment type, with tray-style freeze dryers dominating the market share.

In-depth Analysis of the Freeze Drying Equipment Market

Freeze drying, or lyophilization, is a dehydration process commonly used to preserve perishable materials, making the equipment essential in various industries. Market dynamics are influenced by the expansion of the processed food market, the need for long shelf-life products, and technological advancements improving efficiency and reducing energy consumption.

Key Performance Benchmarks

Performance is measured by drying time, energy consumption, and product quality. Innovations have led to equipment with improved energy efficiency and shorter drying cycles. For instance, superheated steam dryers and fluidized bed dryers have enhanced the drying process, making it more efficient and cost-effective.

Market Share Dynamics

The market features several key players, with GEA Group and SPX FLOW Inc. holding significant shares. These companies invest in R&D to develop advanced solutions for high-quality dried products. The competitive landscape is shaped by strategic partnerships and acquisitions, expanding product portfolios and market reach.

Economic Influences and Consumer Behavior Shifts

Rising disposable incomes and preferences for convenient, long-lasting food products drive demand for freeze drying equipment. The pharmaceutical industry also relies on freeze drying for preserving sensitive biological products, further boosting market growth. Increased investments in food processing infrastructure and the pharmaceutical sector in emerging economies contribute to the market’s positive outlook.

Distribution Channel Preferences

Distribution involves direct sales channels, including online platforms and specialized distributors. Online channels are gaining popularity for their convenience and wider reach. Specialized distributors provide technical support and after-sales services, ensuring customer satisfaction and loyalty.

Recent Innovations and Product Lifecycle Stages

Recent innovations focus on enhancing automation and energy efficiency. For example, vacuum spray drying technology significantly reduces energy consumption and improves product quality. The product lifecycle stages include introduction, growth, maturity, and decline. The current market is in the growth stage, marked by increasing adoption and continuous technological advancements.

Digitalization and Social Trends

Digitalization has transformed the market with real-time monitoring and control of the drying process. IoT and smart sensors have improved efficiency and reliability. Social trends, such as the demand for organic and natural food products, influence the market as consumers seek high-quality dried products with minimal additives and preservatives.

Customer Pain Points and Brand Positioning Strategies

Customers often face high initial investment costs and the complexity of handling advanced equipment. Manufacturers address these pain points by offering customizable and scalable solutions. Brand positioning emphasizes reliability, efficiency, and sustainability, highlighting advanced technologies and energy-efficient designs.

Differentiation Strategies and Niche Markets

Manufacturers differentiate through innovation, quality, and customer service. Advanced features like automated control systems and energy-efficient designs attract customers seeking high-performance solutions. Niche markets, such as preserving rare biological samples and producing customized food products, present growth opportunities for manufacturers investing in specialized equipment and technologies.

Key Factors When Selecting Freeze Drying Equipment

Performance and Functionality

When selecting freeze drying equipment, performance and functionality are paramount. The primary performance metric is the machine’s ability to consistently achieve low temperatures and high vacuum levels. These conditions are crucial for sublimation, the process where ice transitions directly into vapor. High-end models can achieve temperatures as low as -80°C and vacuum pressures below 0.1 mbar, ensuring effective and efficient freeze-drying.

Another critical aspect is the drying capacity. It is essential to consider the volume and type of materials to be processed. Pharmaceutical applications may require precise control over the drying process to maintain the integrity of sensitive compounds. In contrast, food processing might prioritize higher throughput. Machines with adjustable shelves and programmable drying cycles offer greater flexibility and control over the process.

Advanced models also incorporate features such as real-time monitoring and data logging, which allow operators to track the drying process and make adjustments as needed. Microprocessor-based controls and touchscreen interfaces enhance user-friendliness and precision.

Technical Specifications

Technical specifications of freeze drying equipment vary significantly, and understanding these specifications is crucial for making an informed purchase. Key specifications include temperature range, vacuum levels, and shelf area.

Temperature range is a vital parameter, with most laboratory freeze dryers capable of reaching -50°C to -80°C. Industrial models might offer even lower temperatures for specialized applications. The vacuum level, typically measured in millibars or pascals, indicates the machine’s ability to remove air and moisture. Superior models achieve vacuum levels below 0.1 mbar, which is essential for efficient sublimation.

Shelf area and capacity are equally important. Larger shelf areas allow for greater volumes of product to be processed simultaneously, which is essential for high-throughput operations. Additionally, the number of shelves and their adjustability can impact the versatility of the machine, allowing for processing of various product sizes and shapes.

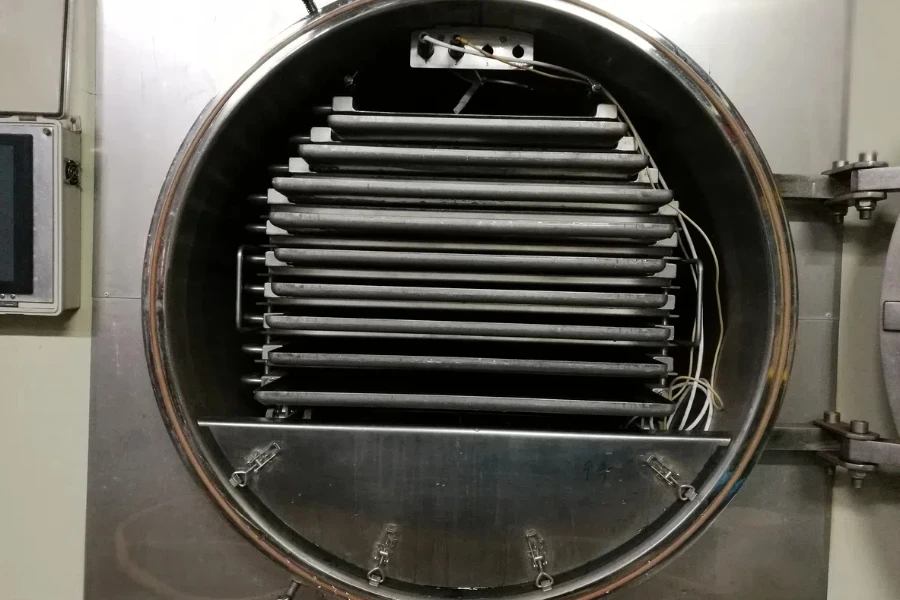

Build Quality and Materials

The build quality and materials used in freeze drying equipment are indicators of durability and longevity. High-quality stainless steel is commonly used for the construction of chamber walls, shelves, and other critical components due to its resistance to corrosion and ease of cleaning.

The insulation of the chamber is another important consideration. Efficient insulation materials ensure minimal heat transfer, maintaining the low temperatures required for freeze drying. This not only enhances performance but also reduces energy consumption.

Attention should also be given to the quality of seals and gaskets, as these components ensure the integrity of the vacuum system. High-quality, durable seals prevent leaks and maintain consistent vacuum levels, which are crucial for the freeze-drying process.

Safety Standards and Certifications

Compliance with safety standards and certifications is essential when selecting freeze drying equipment. Equipment used in pharmaceutical and food industries must adhere to stringent regulatory standards to ensure product safety and quality.

Certifications such as ISO 9001 and CE mark indicate that the equipment meets international standards for quality management and safety. Additionally, equipment intended for pharmaceutical use should comply with Good Manufacturing Practice (GMP) guidelines, ensuring that it is suitable for processing medicinal products.

Safety features such as automatic shutdown, overpressure protection, and temperature alarms are also critical. These features protect both the equipment and the operator, ensuring safe and reliable operation.

Initial Setup and Ease of Use

The complexity of initial setup and ease of use are practical considerations that can significantly impact operational efficiency. Freeze drying equipment should come with comprehensive user manuals and support from the manufacturer to facilitate installation and setup.

User-friendly interfaces, such as touchscreens and intuitive control panels, simplify operation and reduce the learning curve for new users. Programmable drying cycles and pre-set recipes enhance ease of use, allowing operators to achieve consistent results with minimal manual intervention.

Maintenance requirements should also be considered. Equipment with easily accessible components and straightforward maintenance procedures can reduce downtime and extend the lifespan of the machine.

Energy Efficiency and Sustainability

Energy efficiency is becoming increasingly important in selecting freeze drying equipment. Energy-efficient models not only reduce operational costs but also contribute to sustainability goals. Modern freeze dryers incorporate advanced refrigeration systems and energy recovery technologies to minimize energy consumption.

Variable speed compressors and energy-efficient vacuum pumps are features to look for, as they can significantly reduce power usage. Additionally, some models offer energy-saving modes that optimize performance during periods of low demand.

Sustainability considerations also extend to the materials used in construction. Equipment made from recyclable materials and those with a lower environmental impact are preferable. Manufacturers that adhere to environmental standards and certifications further demonstrate their commitment to sustainability.

Advanced Technology Features

The latest freeze drying equipment incorporates advanced technology features that enhance performance and functionality. Real-time monitoring systems allow operators to track critical parameters such as temperature, pressure, and humidity throughout the drying process. This data can be logged and analyzed to optimize future cycles.

Remote monitoring and control capabilities enable operators to manage the equipment from a distance, providing greater flexibility and convenience. Integration with laboratory information management systems (LIMS) and other digital platforms can streamline workflow and improve data management.

Innovative features such as automatic defrosting and cleaning systems reduce maintenance requirements and improve efficiency. Some high-end models also offer customizable drying cycles and advanced algorithms that adjust parameters in real-time to ensure optimal drying conditions.

Cost Considerations and Budget

Cost is a significant factor when selecting freeze drying equipment. Prices can vary widely depending on the size, capacity, and features of the machine. It is essential to balance the initial investment with long-term operational costs and potential return on investment.

High-end models with advanced features and larger capacities may have higher upfront costs but can offer greater efficiency and lower operational expenses over time. Conversely, budget-friendly models may be suitable for smaller operations or those with less demanding requirements.

It is also important to consider the cost of consumables and maintenance. Regular servicing, replacement parts, and energy consumption can add to the overall cost of ownership. A thorough cost-benefit analysis can help determine the most cost-effective option for specific needs.

Practical Applications and Industry Use Cases

Freeze drying equipment is used across various industries, each with unique requirements and applications. In the pharmaceutical industry, freeze dryers are essential for preserving the stability and potency of drugs and vaccines. Equipment used in this sector must comply with stringent regulatory standards and offer precise control over the drying process.

In the food industry, freeze drying is used to preserve the nutritional value, flavor, and texture of products. High-capacity models with efficient energy use are particularly valuable in this sector, where large volumes of product must be processed quickly and cost-effectively.

Other industries, such as biotechnology, research, and cosmetics, also rely on freeze drying equipment for various applications. Each industry has specific needs and challenges, making it essential to select equipment that offers the right balance of performance, features, and cost.

Wrapping Up the Discussion

In summary, selecting the right freeze drying equipment requires careful consideration of various factors, including performance, technical specifications, build quality, safety standards, and cost. By evaluating these factors in the context of specific industry requirements and applications, businesses can make informed decisions that enhance efficiency, productivity, and product quality.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu