In the realm of machinery, the importance of reliable tools cannot be overstated. Among these, the vice grip stands out as a quintessential instrument, known for its versatility and strength. This article delves into the critical aspects of vice grips, uncovering their functionality, design variations, maintenance tips, safety measures, and common applications. By breaking down these elements, we aim to provide a comprehensive understanding of vice grips, enhancing your ability to utilize them effectively in various mechanical tasks.

Table of Contents:

– Understanding the functionality of vice grips

– Exploring design variations and their benefits

– Maintenance tips for long-lasting performance

– Safety measures to prevent accidents

– Common applications in machinery

Understanding the functionality of vice grips:

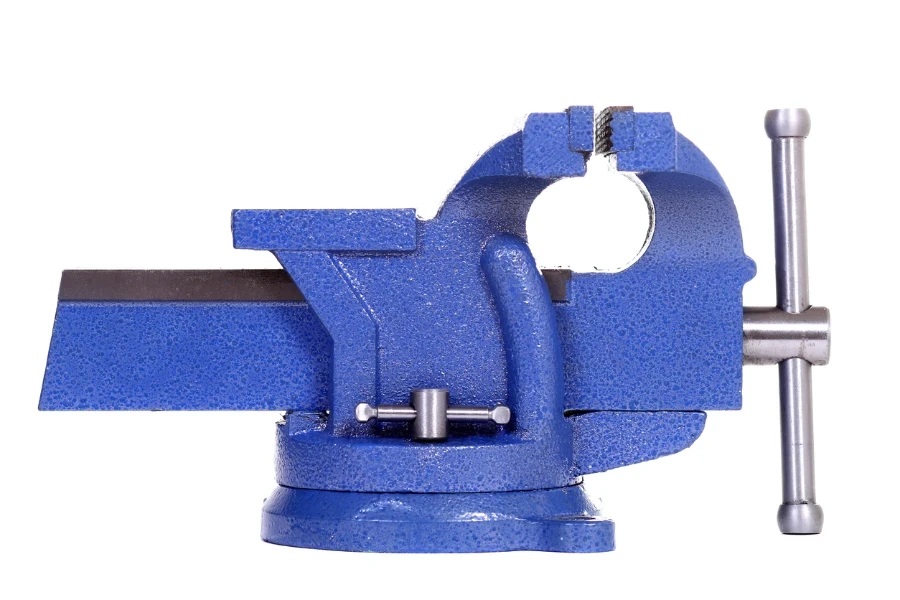

Vice grips are a type of locking pliers that have revolutionized the way we approach holding and manipulating workpieces. Their unique mechanism allows for adjustable pressure, which can be tailored to the specific needs of the task at hand. This adaptability makes them indispensable in scenarios where precision and reliability are paramount.

The core of a vice grip’s functionality lies in its locking mechanism. This feature enables the tool to maintain a firm grip on an object without continuous manual pressure, thereby reducing fatigue and enhancing efficiency. Whether it’s holding a bolt steady or gripping a thin metal sheet, the vice grip adjusts to the challenge effortlessly.

Furthermore, the versatility of vice grips extends to their ability to serve as both a clamping device and a wrench. This dual functionality not only saves time but also reduces the need for multiple tools, streamlining the workflow and minimizing clutter in the workspace.

Exploring design variations and their benefits:

Vice grips come in a variety of designs, each tailored to specific tasks. The most common types include the straight jaw, curved jaw, and long nose designs. Straight jaw models are ideal for gripping flat surfaces, offering maximum contact and stability. Curved jaw vice grips, on the other hand, are better suited for rounded objects, providing a secure grip without slipping.

Long nose vice grips excel in reaching into tight spaces where traditional models cannot fit. This design is particularly useful in intricate tasks, such as electrical work or fine metalworking, where precision is crucial. Understanding the strengths of each design can significantly enhance your tool selection strategy, ensuring that you have the right vice grip for the job.

Additionally, some vice grips are equipped with wire cutters, adding another layer of functionality. This integrated feature allows for quick and easy cutting, making these models a two-in-one solution for tasks that involve both gripping and cutting.

Maintenance tips for long-lasting performance:

Proper maintenance is key to ensuring that your vice grips remain in top condition. Regular cleaning and lubrication of the moving parts prevent rust and corrosion, extending the lifespan of the tool. It’s also important to inspect the jaws and adjustment mechanism for wear and damage, as these are critical to the tool’s performance.

Storing vice grips in a dry, clean environment also contributes to their longevity. Exposure to moisture can lead to rust, which not only compromises the tool’s integrity but also its gripping power. By taking these simple steps, you can maintain the effectiveness and reliability of your vice grips for years to come.

Safety measures to prevent accidents:

While vice grips are incredibly useful, they must be handled with care to prevent accidents. Always ensure that the locking mechanism is securely engaged before applying pressure. This prevents the tool from slipping and causing injury. Wearing protective gloves can also mitigate the risk of cuts or pinches when working with sharp or heavy objects.

Furthermore, when releasing the grip, do so gradually to avoid sudden movements that could destabilize the workpiece or cause the tool to snap back. By adhering to these safety measures, you can utilize vice grips confidently and securely.

Common applications in machinery:

Vice grips find their application in a wide range of mechanical tasks. From automotive repairs, where they can hold parts in place during assembly or disassembly, to welding projects, where they serve as an extra set of hands to hold metal pieces together. Their ability to provide a strong, adjustable grip makes them invaluable in settings where precision and reliability are crucial.

In woodworking, vice grips can be used to clamp pieces together while glue sets, ensuring a tight bond. They are also instrumental in metalworking, offering a secure hold on metal pieces during cutting, bending, or shaping processes. The adaptability of vice grips to various materials and tasks underscores their importance in the machinery toolkit.

Conclusion:

Vice grips are more than just a tool; they are a versatile ally in the machinery world, offering strength, precision, and reliability. By understanding their functionality, exploring design variations, adhering to maintenance and safety practices, and recognizing their wide range of applications, you can maximize their potential in your projects. With this knowledge, the humble vice grip becomes an indispensable part of your toolkit, ready to tackle any challenge that comes your way.