Imagine rushing through the traffic early in the morning for work while trying to grab a cup of hot coffee on the go and, all of a sudden, scalding the coffee in your lap due to the unbearable heat radiating through the thin paper cup!

Thankfully, such a situation can be avoided completely nowadays due to the seemingly simple yet incredibly helpful invention of coffee cup sleeves by Jay Sorensen in 1991.

Today, complementing the practicality of coffee cup sleeves, cup wraps have emerged as another valuable innovation in cup customization and branding. Their development serves as a creative counterpart to Sorensen’s functional design, further enhancing the aesthetic and promotional aspects of cups as well as broadening their customization options.

Read on for an overview of the popularity of cup wraps, and discover essential insights to ensure you are making the most of cup wraps from a retail perspective in 2024!

Table of Contents

Are cup wraps popular?

Tips for cup wrap customization

Embracing uniqueness

Are cup wraps popular?

The rising popularity of cup wraps is clearly reflected in the significant increase in keyword search volume. Google Ads keyword analysis reveals that searches for cup wraps have soared by over 80%, from an average monthly volume of 320 to 590 in the last quarter of 2023.

Among the various printing methods and materials for cup wraps, Ultraviolet Dried Transfer Film (UV DTF) has emerged as the most popular printing mode for cup wraps according to Google Ads keyword analysis. The term: “UV DTF cup wraps”- which means cup wraps made of a particular type of transfer printing method, has seen an impressive average monthly search volume of 1600 over the past year. In terms of material, vinyl serves as the most sought-after type, with the keyword “vinyl cup wrap” having also achieved interest averaging around 70 searches per month as per Google Ads keywords.

The significant rise in search volume not only reflects the escalating interest in cup wrap and its customization but also underscores the growing consumer and business fascination with innovative printing methods like UV DTF, emphasizing their importance in the market.

Tips for cup wrap customization

Material selection

There are quite a number of materials available for cup wraps, with each material choice closely linked to the selected printing method. Paper, for example, is one of the most common materials well-suited for digital printing in view of its ability to produce vibrant, high-resolution designs. However, it is mostly used as basic, short-term cup wraps and often requires an additional adhesive or coating for application, unless it’s specifically designed to stick directly to the cup.

At the same time, heat transfer paper presents a different approach. Specifically designed for transfer printing, which transfers printed designs onto surfaces through heat, this type of paper is perfect for cups made of materials that can endure heat application, such as certain plastics or metals. In this process, the print is effectively transferred from the paper to the cup under the application of heat and pressure.

For more durable and long-lasting applications, film or vinyl materials are the preferred choice, especially when combined with transfer printing methods. Such synergy often brings out high-quality, resilient prints that are resistant to wear and tear, making them ideal for long-term use on various cup types, including plastic and metal.

The growing global awareness of environmental issues in recent years has also led to heightened demand for eco-friendly options in cup wrap customization. Sustainable alternatives like biodegradable films are a prime example, offering quality without compromising environmental values. Additionally, a cup wrap that utilizes eco-solvent inks in the printing process represents another environmentally-friendly option. These inks, produced from refined mineral oil extracts, align well with the preferences of eco-conscious consumers.

Printing methods for design optimization

Even though cup wraps may be produced via traditional printing methods like digital and screen printing, transfer printing is primarily the predominant choice for them in view of the well-rounded quality it offers for customizing cup wraps. This is evident considering that while digital printing is known for its high resolution, it often doesn’t achieve the same vividness as transfer printing, though it is faster and hence may be more cost effective for small runs.

Traditional screen printing, on the other hand, is often preferred for larger batch orders due to its durability and professional appearance. However, it is more for simpler designs, as the image quality might lack the detail found in transfer printing. In a nutshell, transfer printing is preferred for its ability to deliver outstanding image quality with sharp, lively shades and brightness. Furthermore, its compatibility with a wide range of materials, such as plastics and ceramics, allows for the creation of complex and high-quality designs on various surfaces.

Yet among all the transfer printing modes, UV DTF printing stands out for its exceptional image quality and vibrancy in different colors, thanks to UV-curable inks that provide high-resolution, sharp images with vibrant colors. In contrast, cup wraps made of other transfer printing methods, including vinyl heat transfer, may still be able to offer good quality but often not at the same level of detail or color intensity as cup wraps made by UV DTF printing. Such quality enables UV DTF-treated cup wraps to look complex, and full with multi-colored designs.

As a result, most UV DTF cup wraps, such as the one featured in the picture below, also distinguish themselves in terms of durability, and are highly resistant to fading and scratches, while also usually waterproof, ensuring long-lasting visual appeal.

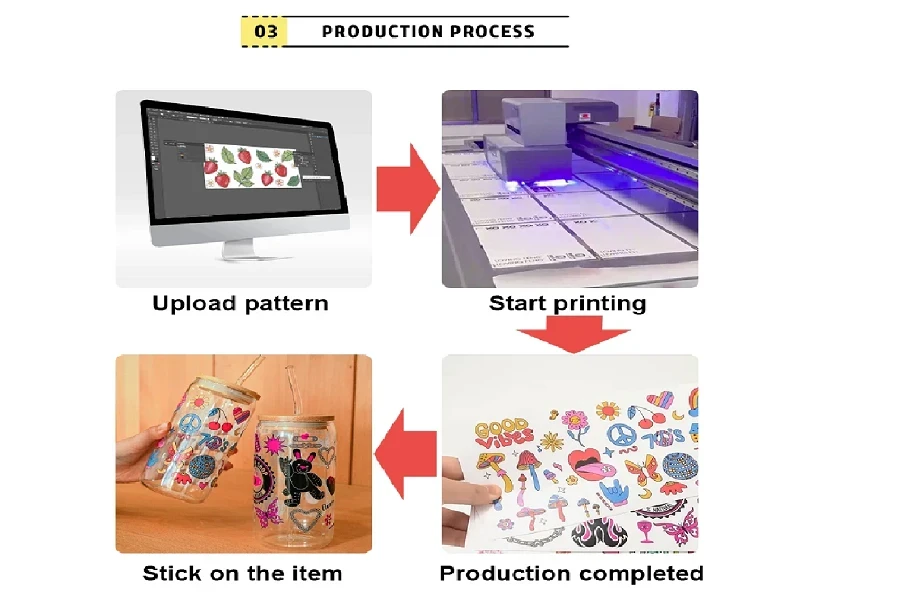

Another notable advantage of UV DTF cup wraps, particularly when compared to other heat transfer methods, lies in their ease of application. Unlike traditional heat transfer processes, UV DTF does not necessitate specialized heat press equipment. This is achievable via the adhesive on the UV-cured film, which facilitates direct application to the cup’s surface by simply removing the protection layer. This simplifies the entire transferring process, making it accessible and straightforward for practically anyone.

Customization options and quality assurance

Aside from material and printing method options, wholesalers’ customization potential largely depends on the flexibility offered by their chosen manufacturers. For instance, a full customization cup wrap provider might offer extensive customization options beyond standard choices like logos, packaging, and graphics, including instant online customization tools without or without templates, but accommodating a wider range of bespoke requests for a more tailored product experience.

In the meantime, for wholesalers prioritizing basic design concepts or overall design outcomes, engaging with a provider that offers sample-based customization can be beneficial. Alternatively, partnering with a provider that supports both design-based and full customization options, including customized sizes, and shapes or even providing free designs, may best meet their comprehensive requirements. Such a full wrap design-oriented customization may often include the ability to support the production of semi-permanent (easier to remove) or permanent full cup wraps to meet different business needs and consumer preferences.

Ultimately, manufacturers adhere to stringent quality control protocols, emphasizing the unique quality aspects and requirements of each product. By consistently monitoring and evaluating print quality, they maintain high standards across all customization options. This is particularly true for providers who prioritize quality control and quality assurance (QC & QA), even if it means getting limited customization options or designing according to given cup wrap templates only to ensure adherence to their rigorous standards.

Embracing uniqueness

The rising trend in cup wraps is evident from Google Ads keyword analysis, showing a consistent upward trend in monthly search volume over the past 12 months. Such a surge, particularly for terms associated with transfer printing technologies like UV DTF, highlights the growing interest in and demand for customized cup wraps.

In terms of tips for customization, it is important for wholesalers to take note of the material and printing technology options available. Businesses can choose from various materials like paper, film, and vinyl, each suited to different printing methods for either semi-permanent or permanent customization. This versatility in design enhancement is complemented by minor or full customization options that emphasize quality assurance, since eventually, the key to successful customization lies in both functional and visually appealing product design.

For more creative ideas, industry insights, and business updates on how to leverage the power of cup wrap customization, visit Alibaba Reads to discover a world of possibilities and to embrace uniqueness in product customization in the business arena.