Businesses can’t run shipping and logistics without investing in protective materials. They are the ultimate means of securing goods during transit, protecting them from damages incurred from unnecessary movement, and keeping them in good condition until reaching their final destination.

The best part is that retailers can choose protective packaging when shipping products. This article will highlight five protective packaging trends sellers can glean in 2024.

Table of Contents

Overview of the global protective packaging market

5 protective and cushioning material trends to leverage in 2024

In conclusion

Overview of the global protective packaging market

Over the years, e-commerce has experienced exponential growth. As a result, the demand for product safety has also gone up. Experts predict the global protective materials market will increase from US $30.4 billion in 2022 to US $48.2 billion by 2032, growing at a 4.8% compound annual growth rate (CAGR).

Here are some important market statistics businesses should know:

- Asia-Pacific currently holds the largest market share, contributing over 40% in 2022

- North America also looks promising, as experts expect the region to record a 5.2% CAGR

- The flexible protective packaging segment contributes 59% of the revenue generated in the global market.

5 protective and cushioning material trends to leverage in 2024

1. Bubble wrap

In the list of protective material trends, bubble wrap emerges as the most versatile. This protective packaging option traps air bubbles in flexible, transparent plastic sheets, allowing them to absorb shock from sudden moves or shifts.

Businesses can use bubble wrap for any product, regardless of shape and size. Not only does bubble wrap shield goods from harm, but it also secures them in place, preventing them from moving around during transit. And if goods should be stored at specific temperatures, bubble wrap also has thermal insulation properties.

Good-quality bubble wrap also has excellent air retention, so it shouldn’t pop too easily—a sign of substandard quality. Although bubble wrap can protect all kinds of items, it is not the best option for heavy-weight goods.

Bubble wrap is popular with many businesses and has been generating real hype. According to Google Ads, this packaging option has retained a healthy 301,000 search interest in 2023.

2. Styrofoam

Styrofoam is a lightweight, protective material that stabilizes products during transit. Manufacturers make them from polystyrene (EPS), and the chosen styrofoam must meet the regional standards where they make them for safe packaging.

But that’s not all. Styrofoam is resilient and completely water-resistant, protecting goods sensitive to moisture from damage. This petroleum-based product is also extremely useful for protecting against bacterial growth.

Styrofoam is relatively cheap and can be custom-molded to fit the seller’s specific needs. As a bonus, styrofoam is recyclable, making it an environmentally friendly packaging option.

Google data shows that styrofoam is also in high demand among businesses. It garnered an impressive and consistent 1.22 million monthly searches in 2023.

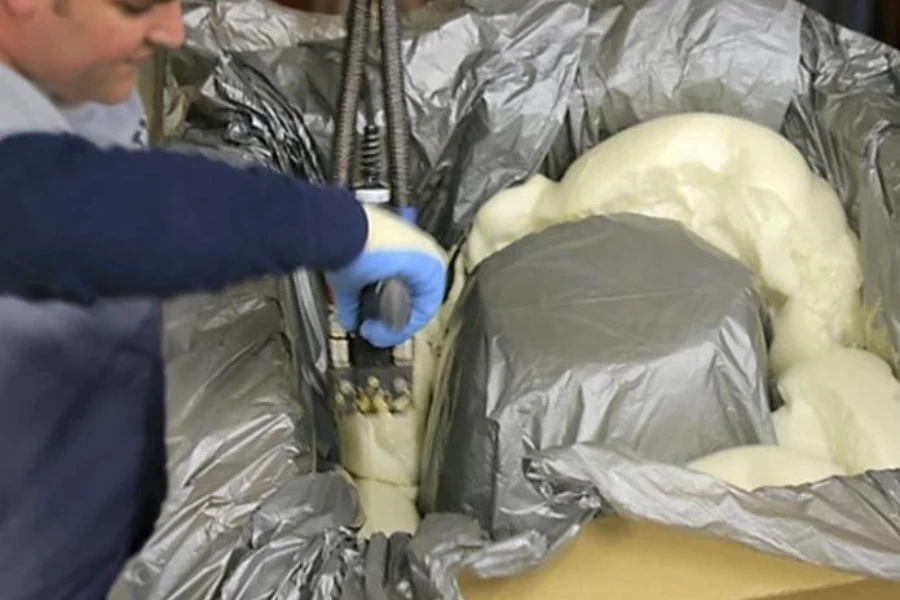

3. Foam-in-place

Foam-in-place is a unique protective packaging trend. Manufacturers craft them from chemical mixtures that expand, encasing any item in a protective layer. This protective packaging is a trusted and effective option. It provides an impressive level of cushioning to protect its contents.

Even better, foam-in-place supports corners and edges, making them one of the most convenient protective packaging. However, businesses must place the foam-in-place evenly around the items to maximize its effectiveness.

Foam-in-place has different types of foam mixtures, each with its own packaging benefits:

- Antistatic eliminates electro-shock statics and is perfect for shipping electronics.

- Polystyrol is less resilient and won’t protect fragile products. But it will suffice for other items.

- Polyurethane is a super-soft-grade foam, ideal for lightweight goods.

- Polyethylene is rigid and great at absorbing vibrations, making it suitable for fragile and valuable items.

4. Loose-fill materials

Manufacturers make loose-fill materials from biodegradable plastics or geofoam to fill spaces in shipping containers hosting lightweight, non-fragile items. Loose-fill materials (or peanuts) are abrasion-resistant and conform to the product’s shape in transit.

All businesses need to do is pour loose-fill materials into their package until it fills up, securing the item from damage and shifting. Loose-fill materials are not the best option for narrow and flat items that are more likely to move than a package.

However, packaging electronics with polystyrene peanuts is not a great idea. They can generate static electricity, which can easily damage such sensitive devices. Instead, they can use anti-static peanuts for such products.

5. Air pillows

Air pillows are protective cushions that use air pressure to keep the items inside a package safe while forming an air barrier. Usually, products go through different climates during shipping, but the extreme ones can affect the air pillow’s protection effectiveness.

For instance, the air pressure in these products will decrease at low temperatures. But at extreme temperatures, air pillows may expand to dangerous levels, potentially damaging the item or the container.

Regardless, air pillows are great protective materials because of their weightlessness—and they don’t add to shipping costs. Air pillows are also hygienic, as they do not cling to wrapped packaging or create a mess when unboxing.

In conclusion

Businesses can ship their products without any form of protective packaging. The shipping process may involve a lot of bumps and unpleasant movements, meaning products have a high chance of arriving damaged, but protective packaging is the perfect solution.

But since there’s no one-size-fits-all approach to protective packaging, businesses have to choose the best ones to secure their products. So, they can select bubble wrap, styrofoam, loose-fill materials, air pillows, and foam-in-place.

These are the top protective and cushioning materials for packaging and shipping 2024.