With the tortilla market set to hit USD 54.66 billion by 2030, selecting the right industrial tortilla machine is crucial. This article breaks down the key factors buyers need to know, helping boost efficiency and meet rising demand while maximizing ROI.

Table of Contents

A summary of the tortilla machine market

6 key considerations for choosing an industrial tortilla machine

Bottom line

A summary of the tortilla machine market

Tortillas are a symbol of Mexican cuisine. Consumers can use them to make many amazing dishes, from burritos to tacos and enchiladas. These flatbreads are nutrient-rich and packed with proteins, minerals, and vitamins. They are incredibly popular, with people searching for them an average of 100,000 to 1 million times every month.

In 2023, experts estimated the global Tortilla market at USD 37.7 billion. They expect it to grow to USD 54.66 billion by 2030 at a 5.45% compound annual growth rate (CAGR). The market shows promising growth thanks to the rising number of health-conscious consumers, increasing demand for ready-to-eat foods, and the rising popularity of tortillas.

North America is the leading region in the global tortilla machine market, and the popularity of Mexican cuisine contributes to its expansion. Asia Pacific is also growing steadily, thanks to a combination of traditional cooking methods and an increasing appetite for quality.

6 key considerations for choosing an industrial tortilla machine

1. Production capacity

The first thing any business must determine is how many daily tortillas it wants to make. This will guide it towards the right machine. Tortilla machines come in all sizes, producing 500 to 4,000 tortillas per hour. For most small—to mid-sized businesses (like casual restaurants or local vendors), machines that crank out about 1,200 to 2,000 tortillas an hour tend to hit the sweet spot.

If the business needs higher production, it should consider machines that pump 3,000 to 4,000 tortillas per hour. Such tortilla machines are also the best bet for big chain restaurants or large-scale facilities. Conversely, slower machines making fewer than 1,000 tortillas per hour (quite slow) could be perfect for smaller businesses or newcomers with lower demand.

For example, a business aiming to hit 10,000 tortillas daily would need a machine producing at least 1,250 per hour to meet that goal during an 8-hour workday. Remember that if it goes for lower-capacity machines, it will slow down the business’s operations, resulting in unnecessary inefficiencies.

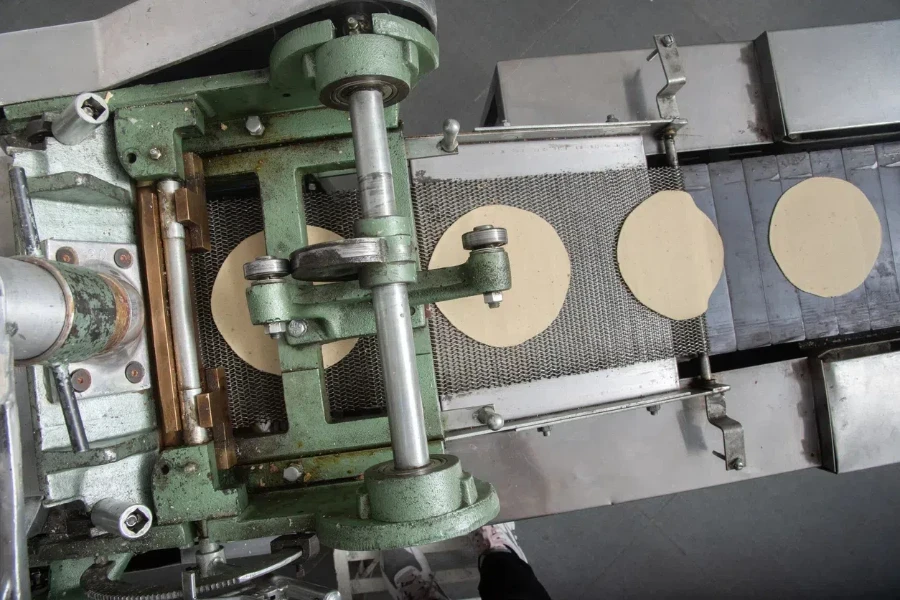

2. Tortilla size

What size and thickness should the tortillas be? This is another concern businesses need to address before selecting their ideal tortilla machine. Different regions and markets may prefer tortillas with specific dimensions and thicknesses. For example, tortillas used for burritos are usually larger, measuring about 10 to 12 inches in diameter. They’re also thicker to handle all those hearty fillings.

In contrast, Mexico often favors smaller, thinner, and softer 6-inch tortillas, perfect for tacos and other traditional dishes. That’s why businesses must ensure their chosen machine can produce tortillas in the desired size and thickness. Thankfully, many modern tortilla machines can handle sizes from 6 to 12 inches and let operators tweak the thickness from 1.5 mm to 3 mm.

This versatility is important for businesses hoping to expand to different markets or their menu. Machines with limited options could do more harm than good, making meeting customers’ varied tastes harder.

3. Automation level

The automation level of a tortilla machine can greatly impact a business’s operations. Fully automatic machines can care for almost everything, from feeding the dough to ejecting the tortillas, with little to no human involvement. These machines often operate at speeds of 2,500 to 4,000 tortillas per hour and need only one operator for monitoring, leading to reduced labor costs and increased efficiency.

On the other hand, manual machines require operators to handle tasks like dough preparation and tortilla inspection. Because of this more hands-on involvement, they produce between 500 and 1,500 tortillas per hour. Although businesses will have more control over tortilla quality, it can increase labor costs.

When choosing the right level of automation, businesses should think about labor costs, production volume, and the amount of control they want. While fully automatic machines can save labor and boost output, they usually come with a large initial investment ranging from USD 20,000 to USD 100,000.

In contrast, manual machines may cost less initially (USD 5,000 to USD 15,000) and offer more production flexibility. Still, they require ongoing operator training and supervision to maintain quality and efficiency—which means more labor costs.

4. Material and construction

The strength and lifespan of an industrial tortilla machine largely depend on the materials used in its construction. Businesses should look for machines featuring rigid materials that can handle heavy use and challenging environments. Stainless steel is popular for food processing because it’s strong, rust-resistant, and easy to clean.

Also, pay attention to the machine’s safety features, like emergency stop buttons, protective guards, and non-slip surfaces. A well-designed machine will always help reduce the chance of accidents or injuries.

5. Cost and ROI

The price of an industrial tortilla machine depends on the features and size businesses want. When deciding which one to buy, consider the long-term benefits and how it could give a good return on investment (ROI). If the tortilla machine offers higher production capacity, lower labor costs, and better product quality, it will lead to a positive ROI.

Additionally, look at the total cost of ownership, including the initial cost, maintenance, and energy use. Get quotes from different manufacturers, and remember to factor in extra costs for installation, training, and ongoing support.

6. Additional features

Some industrial tortilla machines have extra features that make them more flexible and customizable. These might include:

- Multiple cooking zones to cook tortillas with different thicknesses or browning levels.

- Automatic tortilla ejection to boost efficiency and reduce the need for manual handling.

- Integrated dough preparation systems to streamline the production process.

- Customizable controls allow users to adjust the machine’s settings to fit their needs.

When considering these features, consider future production goals and any specific needs. A versatile machine can give businesses more flexibility and help them adapt to changing market demands.

Bottom line

Tortillas are trendy dishes in high demand online (up to 1 million searches) and offline. Many consumers looking for them want ready-made tortillas for whatever meal they want to enjoy. Hence, businesses need tortilla machines to keep up with the rising demand.

However, like other equipment, businesses must pay attention to the tortilla machines they want to prevent unwanted accidents or terrible performance. Consider all the factors discussed in this article when searching for manufacturers to ensure businesses only get the best tortilla machine for their needs and budget.