A CNC lathe and a CNC mill are used in the workshop to shape and cut different materials. Though they are used in the same place and do the same work, a CNC lathe and a CNC mill are different in the technique they use.

This article will look at the key differences between a CNC lathe and a CNC mill. Also, we will discuss what each machine is used to create.

Table of Contents

What is a CNC lathe?

What is a CNC mill?

Key difference between a CNC lathe and a CNC mill

Conclusion

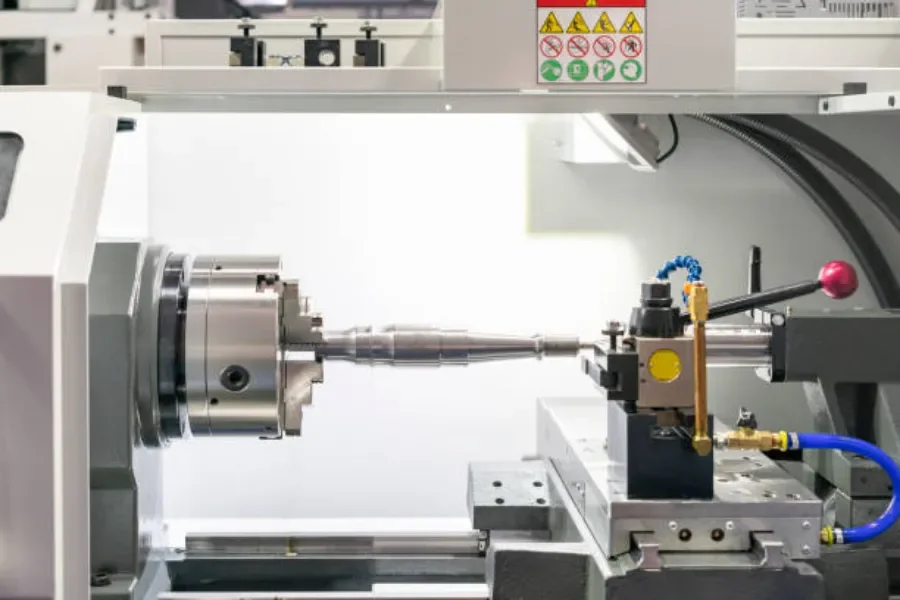

What is a CNC lathe?

A CNC lathe is a machine that removes undesired material from a rotating workpiece. The material goes off in the form of chips with the help of a tool that cuts across the work and can be fed deep into the work. As the machine rotates the workpiece on the axis, it performs functions like knurling, cutting, and facing.

The lathe machine can work with both wood and metal. On the headstock is a chuck that holds the workpiece in place and continuously rotates it. At the same time, the tool holder clutches the cutting tool which is tightened carefully to avoid movements.

Pros:

- High productivity as they give high-quality products with first-rate accuracy

- Can produce many products within less time due to its automation

- Saves time and money due to reduced operators or turners which in turn minimizes labor cost

- Have an unrivaled range of functions, thus offering more options to buyers

Cons:

- Has limited structures and shapes as it is only preferred for cylindrical shapes

- High initial cost renders lathe machines quite expensive

- Take up large space because they are huge and require extra attachments and fittings

- High-skilled turners are required to operate the machines which could be costly

- Need constant maintenance for the vital parts

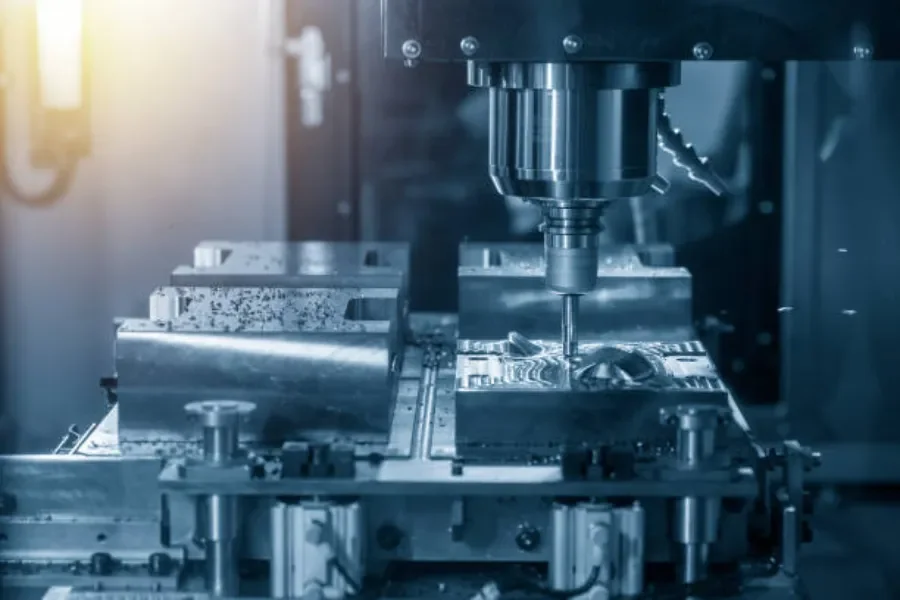

What is a CNC mill?

A computer numerical control mill is a machine that employs rotating multi-point cutting tools and computerized controls to gradually remove material from a workpiece. The cutting tool is well-placed on a spindle or arbor to rotate at high speed. A workpiece is held on the machine’s table which moves to control the feed of the workpiece.

The work tables on milling machines move in three directions. While the X-axis advances right and left, the Y-axis moves in and out, and the Z-axis proceeds up and down. CNC milling machines have gained popularity in woodworking, metalworking, and prototyping.

Pros:

- Quick as the process has short lead times

- Has good tolerances

- Compatible with many materials

Cons:

- There is a lot of waste after the milling process

- Achieving a certain design on a piece requires several tools, operations, and the machine

- The complexity and features are limited for the final pieces

- Milling equipment is quite expensive

6 key differences between a CNC lathe and a CNC mill

1. Operation method

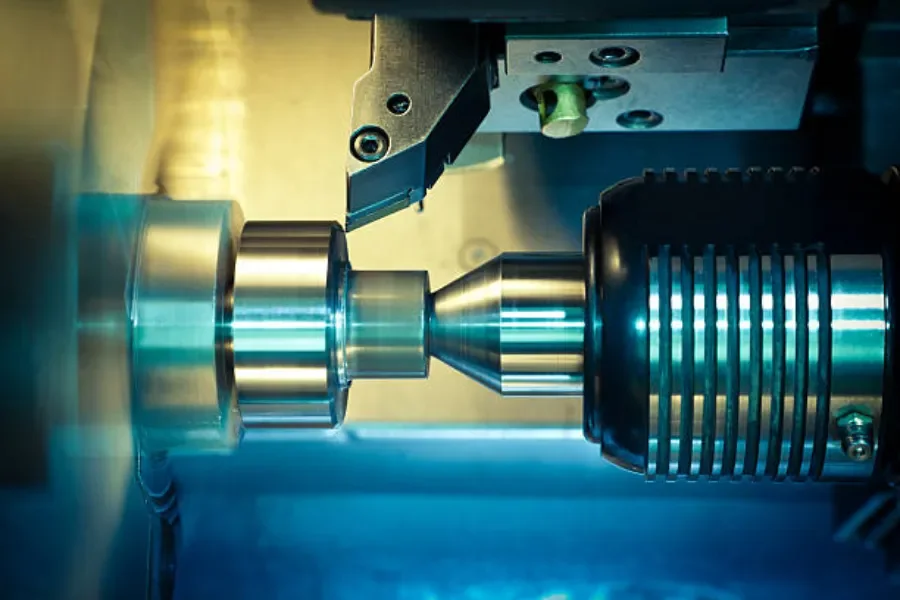

This is the major difference between milling and lathe machines. It involves the relationship between the workpiece and the tool. The workpiece spins about its axis in lathe machines over a stationary cutting tool. The turning movement helps create cylindrical parts. It is the preferred choice when creating repeatable and quick symmetrical cylindrical parts.

On a milling machine, the tool rotates about its axis while the workpiece remains stationary. The tool can approach the workpiece in various orientations desired on more complex and intricate parts.

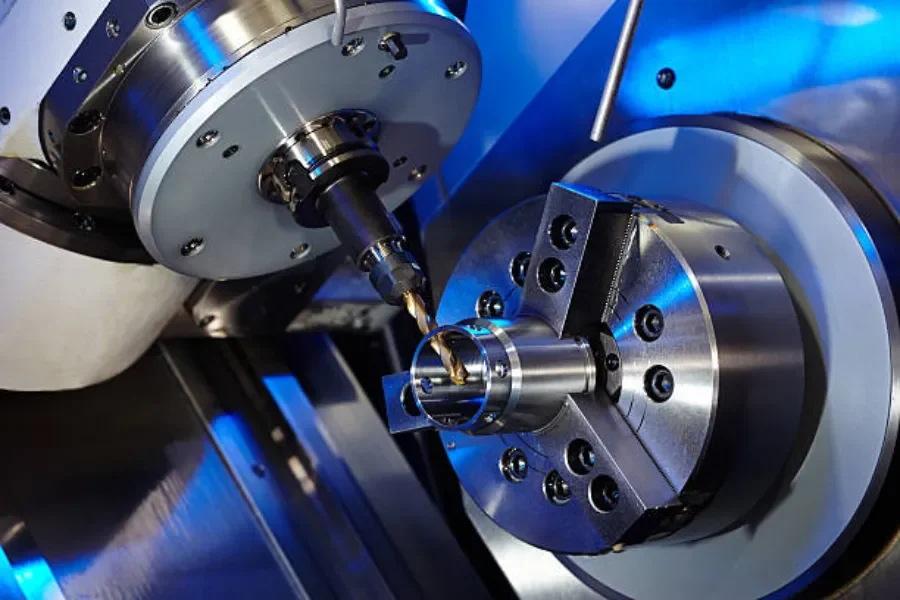

2. Cutting tools

For the lathe machine, the insert cutter is the primary cutting tool. It has a removable tip that helps in shaping and cutting objects. Whereas, the milling machines have the end mill option which can be operated at various speeds when functioning.

3. Cost

The cost varies according to the equipment, size, materials, accuracy and design, manufacturing volume, finishing operations, and automation of these machines. The setup costs influence the cost of these machines.

Milling machines cost more than lathes. This is because they possess more complex moving parts. The components are harder to set up, operate, and maintain. The machining parts are also designed for more sophisticated functions. Therefore, mills are generally more expensive in various other operations compared to lathes.

4. Usage

The milling and lathe machines are used to execute various functions. A mill can perform the following operations:

- Side milling

- Facing

- Milling slots, keyways, and grooves

- Sawmilling

- Plain milling

- Threading

- Gang milling

- Helical milling

- Straddle milling

- Form milling

On the other hand, a lathe machine has the following functions:

- Thread cutting

- Turning

- Facing

- Boring

- Counterboring

- Spot facing

- Reaming

- Cutting

- Sanding

- Chamfering

- Knurling

5. Applicable materials

Products made from milling machines are used in sectors like automobiles, telecommunications, machinery, and electrical components. The various materials applied as workpieces include plastics and most metals. The common materials are:

- Brass

- Aluminum

- Magnesium

- Steel

- Titanium

- Nickel

- Thermoset plastics

- Zinc

When it comes to lathe machines, various materials can be used. The materials must be within the size limitations of the machine. This is because they affect several aspects of manufacturing like the rotation speed. The most preferred materials are:

- Plastics

- Titanium

- Aluminum

- Steel

- Delrin

- Wax

Conclusion

In summary, both milling and lathe machines can remove material from a workpiece but differ on the removal technique. Buyers should understand that lathes entail rotating a workpiece against a single-bladed cutting tool.

On the other hand, milling machines rotate a pointed or multi-bladed cutting tool against a stationary workpiece. Apart from functionality, they should also consider the advantages and disadvantages of both the lathe and milling machines. To find quality CNC equipment, visit Alibaba.com.