Grinding discs can grind, cut, and polish all kinds of stuff—metal, stone, you name it. They come in tons of varieties, each with its own strengths.

Choosing the right disc is actually a big deal since it’s not just about finishing the job but doing it well. Take surface grinding, for example. Super smooth, flat surfaces are crucial for several industries. When working on cars or buildings, we need that perfect finish.

Let’s learn more about the different types of discs, what they’re best for, and how to pick the right one for your business.

Table of Contents

Types of grinding discs

Top considerations when buying grinding discs

Understanding grit size

Summary

Types of grinding discs

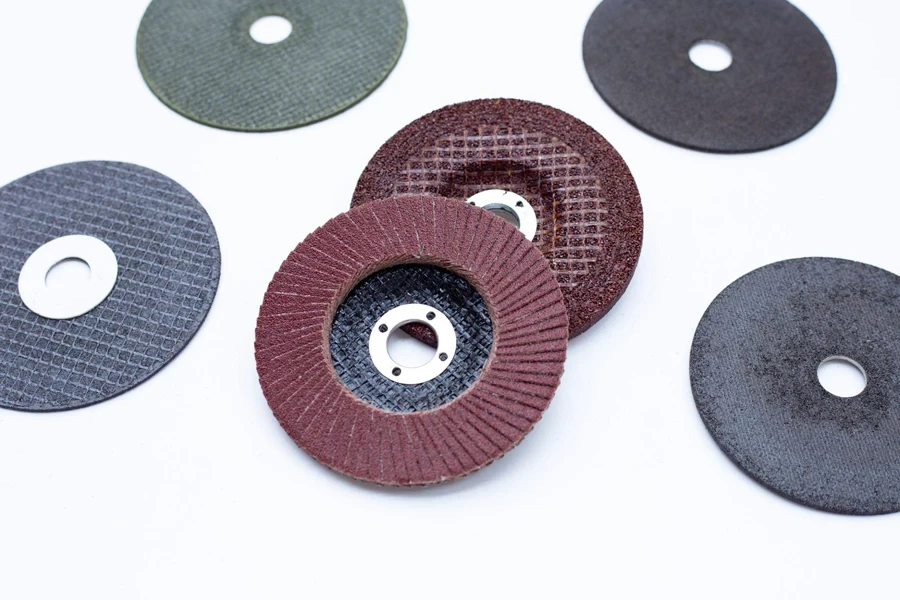

Here are the main types of grinding discs worth considering depending on your needs:

Bonded abrasive discs

These are known to be tough, as they’re made by sticking abrasive bits together with strong glue-like stuff. They’re great for heavy-duty jobs, such as grinding or cutting through some really rugged metal.

Bonded abrasive discs come in all sorts of shapes and sizes, and they can take a beating without falling apart. If you have a huge metalworking project, these are your go-to discs.

Coated abrasive discs

Coated abrasive discs are perfect for grinding a thin layer of gritty stuff stuck onto something flexible, like paper or cloth. If you need to do some fine-tuning or get a smooth finish, look no further. You can bend them slightly, which is great for working on curved surfaces. Woodworkers, car detailers, and metal finishers love these for sanding and polishing.

Diamond grinding discs

These discs have actual industrial diamonds on them. They’re super hard and can cut through stuff like stone and concrete like it’s butter. They last forever, too. If you’re working with really tough materials or need to be super precise, diamond-grinding discs are your best bet. Construction workers and tile setters prefer using diamond grinding discs, as they’re sturdy enough to handle tough elements.

Flap discs

Flap discs are more like a bunch of sandpaper sheets all fanned out in a circle. They’re kind of a jack-of-all-trades—best for grinding and finishing. Welders and metal fabricators use them as they can do rough work and finishing touches with the same disc.

Top considerations when buying grinding discs

Here’s what you really need to think about when picking a grinding disc:

Material compatibility

This should top your checklist, as different discs are made for different materials. Using the wrong one isn’t just inefficient—it could damage your work or even be dangerous. For instance, diamond discs are great for hard stuff like stone and concrete, while bonded abrasive discs are your go-to for metal. Most of all, check what the manufacturer recommends for the material you’re working with.

Grit size

Think of this like sandpaper grades. Lower numbers (coarser grits) remove material quickly but leave a rougher finish. They’re great for when you need to get rid of a lot of material fast. Higher numbers, on the flip side, (finer grits) give you a smoother finish—perfect for polishing or final touches.

Disc diameter

Size matters here. Bigger discs cover more area, which is great for large jobs. Smaller ones give you more control over detailed work. The primary thing here is to match the disc size to your grinder. Using the wrong size can be ineffective or even unsafe. Common sizes range from 4 inches for small jobs to 9 inches for bigger stuff.

Bond type

This is about what holds the abrasive grains together. Resin bonds are flexible and good for lots of different jobs. Vitrified bonds are more rigid and heat-resistant, great for precision work. Metal bonds are super tough, often used in diamond discs for heavy-duty jobs. The bond affects how the disc performs, so choose based on what you’re doing.

Speed rating (RPM)

This has all to do with safety. Every disc has a maximum speed it can handle safely. Going over that speed is somewhat risky—the disc could break apart. Always check that your grinder’s speed matches or is lower than what the disc can handle. It’s okay to use a disc rated for higher speeds than your tool, but never the other way around.

Thickness

Thicker discs last longer and can handle more pressure—great for heavy grinding. Thinner ones are better for precision and fine work. Think about whether you need to remove a lot of material or if you’re doing detailed finishing work.

Understanding grit size

Let’s break down grit size in a way that’s easy to grasp:

Coarse grit size (16 to 30)

They’re rough and ready, with big, abrasive particles that do the job quickly. Here’s what you need to know:

- Best for: Removing lots of material quickly, like stripping rust or paint or grinding down welds.

- Great for: Initial stages of metalwork, woodwork, and construction projects.

- The catch: They leave a rough finish, so you’ll need to follow up with finer grits.

- Pro tip: Use these when speed is more important than a smooth finish.

Medium grit size (36 to 60)

These are your all-rounders. Not too rough, not too smooth—just right for many jobs:

- Perfect for: Smoothing out surfaces after using coarse grits or general-purpose grinding.

- Ideal in: Metalworking for blending welds, woodworking for initial sanding.

- The balance: Good material removal with a decent finish.

- Why you’ll love them: Versatility

Fine grit size (80 to 120 and above)

These are for when you want things smooth as silk:

- Best used for: Final touches, polishing, and preparing surfaces for paint or finish.

- Shines in: Metalwork for creating a polished look, woodwork for pre-finish sanding.

- Not great for: Removing lots of material—that’s not their job.

- The payoff: A super smooth, professional-looking finish.

Remember, start with coarse grits and work your way up to fine for best results. It’s like climbing a ladder since each step gets you closer to that perfect finish.

Summary

Understanding the ins and outs of grinding discs is key to getting great results, whether you’re working on a big project or a small DIY job. It’s not just about picking any disc off the shelf – there’s a bit more to it than that.

First off, grit size is a big deal. Looking for a smooth finish? A fine grit is your friend. And for those in-between jobs, medium grit discs have got you covered. Whether you’re grinding down rough metal or putting the finishing touches on a wooden surface, picking the right disc makes all the difference. It’s about matching the disc to what you’re working on and want to achieve.