If businesses want to make money roasting nuts (whether a small-batch artisan or running a large-scale operation), choosing the right nut roasting machine can make a big difference in their product quality, efficiency, and overall success. But with so many options available, it’s easy to feel overwhelmed when trying to pick the best one for your business needs.

This guide will walk retailers through the key things to consider when selecting a nut-roasting machine, so they can confidently choose the best options for their buyers in 2025.

Table of Contents

Type: Pick the right model for roasting needs

Product capacity: Matches required production volume

Temperature control: Offers precise roasting settings

Energy efficiency: Reduces operational costs

Ease of use: Simplifies operation and maintenance

Safety features: Ensures reliable and secure operation

The bottom line

1. Type: Pick the right model for roasting needs

The first thing businesses must consider is the type of roasting machine that fits their operation. Every nut roaster has pros and cons, but it depends on what kind of nuts brands are roasting and how big their production is.

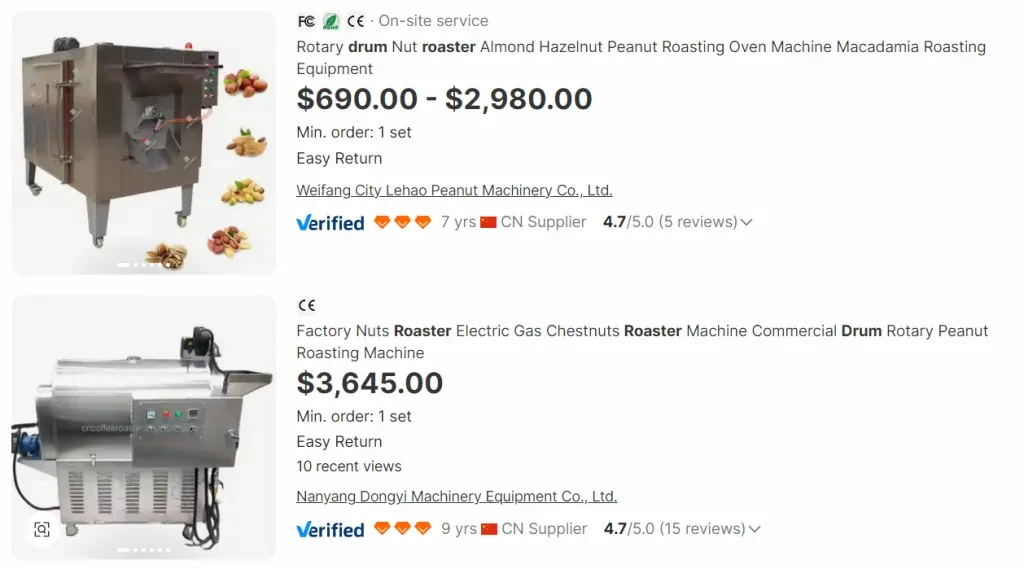

① Drum roasters

Drum roasters are common in the nut-roasting world. They work by tumbling nuts inside a rotating drum, which helps roast them evenly as they roll around. This type of roaster is a good option if businesses work with larger batches.

Why it’s a good choice

- Great for high-volume production.

- The tumbling action helps distribute heat evenly so all the nuts roast at the same pace.

- Businesses can roast a wide variety of nuts.

Drawbacks

- Since these nuts get the same heat, businesses may have less control over how each nut roasts.

- Preheating and cooling can take some time.

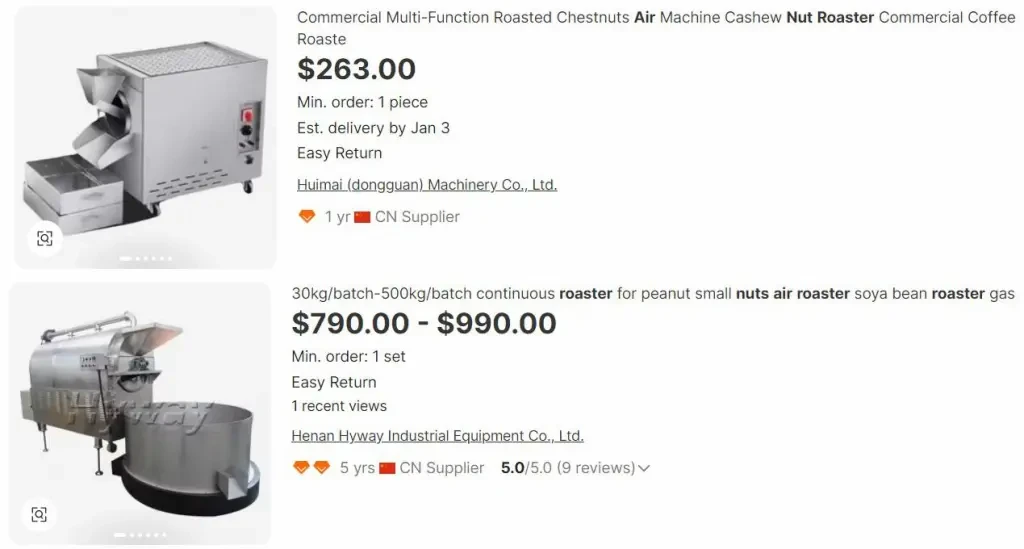

② Air roasters

Instead of heating the nuts directly, air roasters use hot air to roast them. These machines are faster and offer more precise control over the roasting process, which is ideal when fine-tuning is needed.

Why it’s a good choice

- Faster roasting times compared to drum roasters.

- Businesses get more control over temperature and roasting time.

- This machine is perfect for nuts that need greater handling.

Drawbacks

- More expensive upfront compared to drum roasters.

- Since they use hot air, they might require more maintenance.

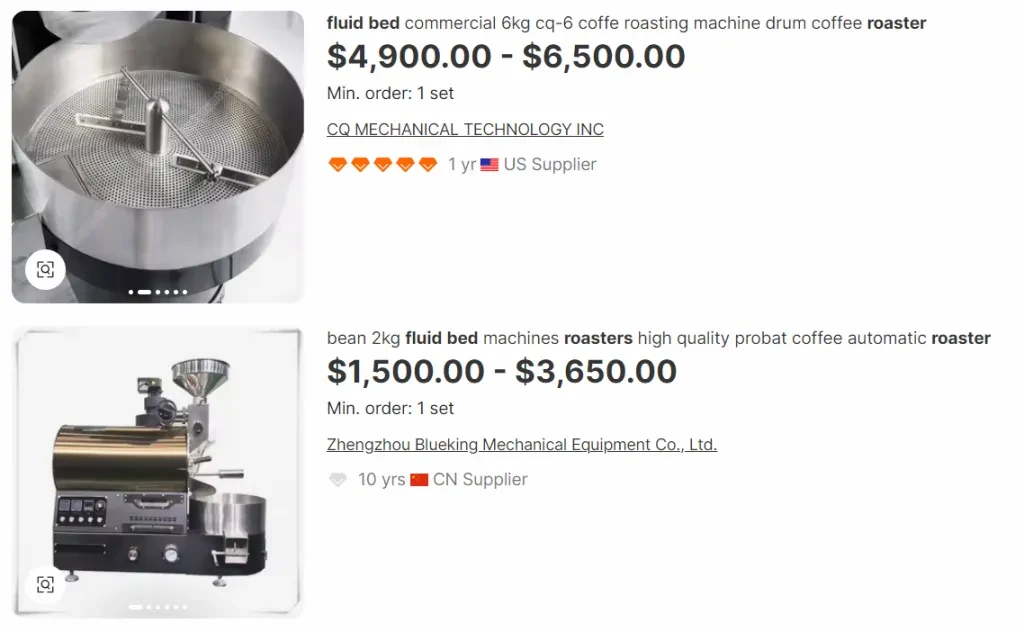

③ Fluid bed roasters

Fluid bed roasters are air roasters that use hot air to make the nuts “float” while they roast. This method ensures the nuts don’t sit in one place for too long, so businesses get a really even roast.

Why it’s a good choice

- Highly efficient and consistent.

- Lower chances of burning or over-roasting.

- This machine can give businesses a uniform roast across the board.

Drawbacks

- These are usually pricier and a bit more complex.

- They’re not as easy to find for smaller businesses.

④ Batch vs. continuous roasters

- Batch roasters roast nuts in individual, separate batches, making them perfect for smaller operations or companies that frequently need to switch between different nut types.

- On the other hand, continuous roasters run constantly, feeding nuts through a system for consistent roasting. These are best for big businesses focused on volume and efficiency.

2. Product capacity: Matches required production volume

How much can the machine roast at one time? That’s one of the most important things businesses must figure out. Different machines have different roasting capacities, and brands will want to pick one that matches their current production needs (and leaves room to grow).

Machines that handle 5-20 kg (about 11-44 pounds) per batch are great for artisanal or smaller operations. These give businesses more control over the process and are generally easier to manage.

However, if they’re roasting in large quantities—say, 50-200 kg (110-440 pounds) per hour—look for machines that can handle that volume. These machines are designed to be more efficient and can keep up with higher demand.

Pro tip: When choosing a machine, plan for the future. If the business is growing, brands will want a machine that can handle more nuts down the road. Investing in a machine that can handle more production as the business expands is better than outgrowing the equipment too soon.

3. Temperature control: Offers precise roasting settings

The flavor and quality of roasted nuts depend on how well users control the temperature. Different nuts require different roasting temperatures and times, so having a machine that lets them fine-tune these settings is key.

Nuts don’t all roast the same way. Almonds, for example, like it hot, between 280°F and 300°F (137°C to 149°C), while cashews need a gentler touch, usually roasting at lower temperatures like 250°F to 270°F (121°C to 132°C). A flexible temperature-setting machine will help businesses get the best results for different kinds of nuts.

Similarly, some advanced machines let users program specific roasting profiles, meaning they can set and forget them. They can also store profiles for different nuts, which helps if brands roast many varieties.

4. Energy efficiency: Reduces operational costs

Energy use is an important factor because it directly affects the bottom line. A more energy-efficient machine will save businesses money in the long run, and it’s better for the environment, too. For energy efficiency, users must choose between gas and electric nut roasters.

Gas-powered machines are more cost-effective if businesses roast many nuts, as they heat up quickly and can handle larger batches. In contrast, electric machines are typically more precise, which is great if users need exact control over their roast. However, depending on the local energy rates, they may cost more to run.

Businesses must also consider insulation and heat retention. Well-insulated machines lose less heat, requiring less energy to stabilize roasting temperatures. Hence, brands must look for machines designed to keep heat in, as this will make them more efficient and save on energy costs.

5. Ease of use: Simplifies operation and maintenance

No one wants to spend hours fiddling with complicated controls or taking apart a machine for cleaning. The easier the machine is to use and maintain, the less downtime and hassle businesses will have.

Some machines have digital displays and simple controls, making setting adjustments and monitoring the roasting process easy. Businesses should also look for features like touchscreen controls, automatic temperature adjustments, and alarms that alert if something’s off.

Remember that roasting nuts leaves behind oils and bits that users must clean out regularly. Machines that are easy to take apart and clean will save them a ton of time. Some even come with self-cleaning features or removable parts that make maintenance a breeze—look for those.

6. Safety features: Ensures reliable and secure operation

No matter the size of the operation, safety should always be a top priority when choosing a nut-roasting machine. Roasting nuts involves high heat and machinery with moving parts, so businesses must look for machines with essential safety features to protect their workers and equipment. Here are a few safety features to consider:

① Temperature sensors and alarms

Although roasting nuts at too high a temperature can ruin the batch, it can also create safety hazards like overheating or fire risks. Machines that come with built-in temperature sensors and alarms help prevent these accidents. If the machine detects that the temperature rises too high, it will alert the operator to make adjustments immediately.

② Emergency shut-offs

Look for machines with an emergency shut-off feature. If something goes wrong, such as a mechanical or overheating problem, users can quickly turn the machine off to prevent further damage or danger.

③ Safe design features

Some machines have safety-focused designs featuring insulated surfaces to prevent burns and secure, covered areas where the nuts roast. This minimizes the risk of injury for operators working closely with the machine.

The bottom line

Choosing the right nut-roasting machine can have a major impact on business, so it’s important to take the time to consider all the key factors. Each aspect plays a role in finding the perfect machine for your operation, from the type of roaster to its capacity, temperature control, and energy efficiency. With the right roasting machine, brands can create consistently high-quality roasted nuts that customers will love while keeping their operation running smoothly and efficiently.