Table of Contents

What is a CNC router?

What materials can be cut with CNC router machines?

What applications are CNC router machines suitable for?

How does a CNC router machine work?

How much does a CNC router cost?

How to choose a CNC router table

What are the different types of CNC router machines?

What software can be used for CNC router machines?

Which controllers can be used for CNC router machines?

What should you know before buying a CNC router machine?

How to order a CNC router machine

FAQs

What is a CNC router?

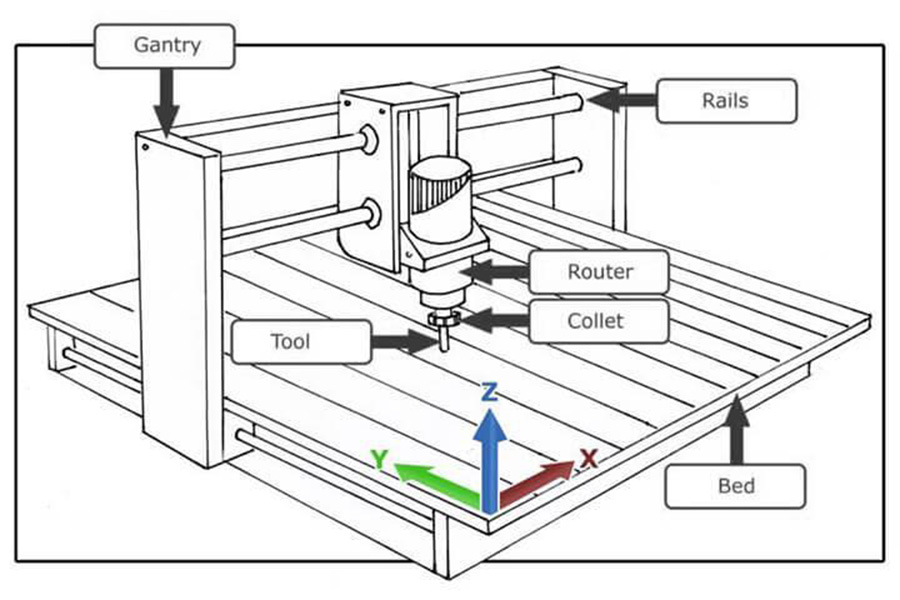

A CNC router is a type of automatic machine tool used with a CNC system for automatic carving, engraving, cutting, milling, drilling, and grooving of different materials. Materials such as wood, foam, stone, plastics, acrylic, glass, ACM, copper, brass, aluminum, PVC, and MDF can be worked on. These machines can produce very precise and complex shapes and contours by machining materials using a tool. A CNC router machine achieves these results using a minimum of three axes, X, Y, and Z. The X-axis is horizontal, left to right, the Y-axis is backward and forward, and the Z-axis is vertical, i.e. up and down. These, seen figuratively, result in a so-called portal, which is why CNC routers with a portal formation (an X-axis designed as a bridge) are often called portal milling machines. In addition, some milling machines have A-, B-, and C-axes representing a rotation around the main X, Y, and Z axes.

What materials can be cut with CNC router machines?

CNC router machines can cut many different materials, including:

Wood

Foam

MDF

Plastics

Acrylics

Stone

Copper

Brass

Aluminum

Glass

ACM

PVC

What applications are CNC router machines suitable for?

Here are some of the versatile application possibilities of CNC router machines:

- 2D carving

- 3D carving

- Woodworking

- Aluminum fabrication

- Acrylic fabrication

- Exhibits and fixtures

- Architectural millwork

- Cabinet making

- Sign making

- Door making

- Furniture production

- Mold making

- Decorations

- Musical instruments

- Aerospace

How does a CNC router machine work?

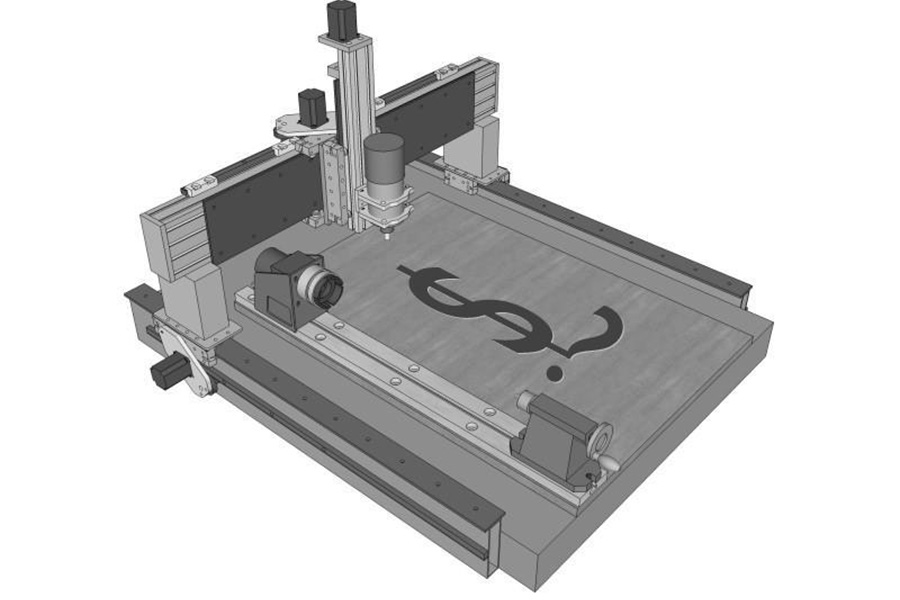

A CNC router machine is computer-controlled. All necessary data, in the form of G-codes, are assembled into a CNC program. G-codes consist of any word in a CNC program that begins with the letter G. It tells the machine tool what type of action to perform, such as rapid movement or controlled lines or arcs. Since these codes are standardized, they can be based on CNC router software used in almost all CNC router machines. When all the data has been input and the CNC program is ready to go, the CNC machine gets to work. Manufacturers have added their own codes to the ISO G-codes, therefore, several post-processors exist to generate “matching” programs from CAM programs for different machines.

By rotating the respective tool, or using an adapted spindle opposite the clamped workpiece, the cutting movement necessary for the desired work is generated. This is pre-determined based on the G-codes. The CNC tool moves around the workpiece, creating the predetermined shape. This can be achieved, depending on the router design, by displacement of the workpiece on a movable CNC router table. By using all available axes, almost all workpiece geometries are possible. The following forms can be created:

3D models suitable for architecture and model construction

3D freeform surfaces

Roto-symmetrical workpieces

Lettering in both 2D and 3D

Engraving in 2D and 3D

Threads

Grooves

How much does a CNC router cost?

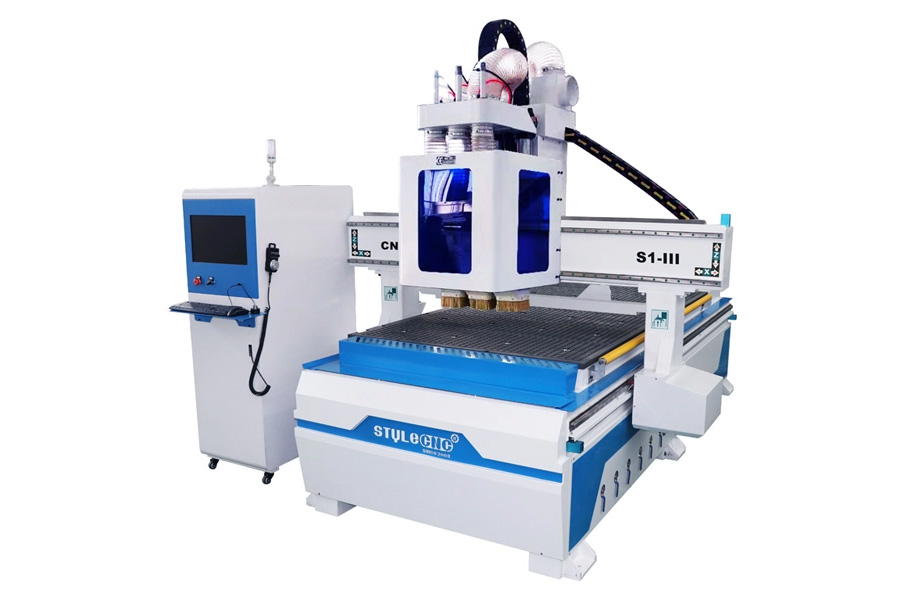

CNC router cost depends mainly on its configuration. Although you may think all CNC routers look the same, there are significant differences between what they can do. All machines carry out basic functions such as cutting, hollowing, lettering, plane carving, relief, and so on, but the accuracy, intricacy, speed, functionality, and price vary enormously.

- Small CNC router price range: $2,500 – $5,000

- Standard CNC router price range: $3,000 – $10,000

- ATC CNC router price range: $16,800 – $25,800

- 5-Axis CNC router price range: $95,000 – $180,000

- Smart CNC router price range: $8,000- $60,000.

Are there additional costs and fees when you buy a CNC router?

In addition to the machine itself, you’ll need to purchase a computer-aided design (CAD) software package to create your designs. Those usually run anywhere from $2,000 to $15,000.

Training usually costs anywhere from $200 to $500 per day. Depending on the current knowledge level of your staff, the process could take a few hours or several days. Installation also tends to cost between $200 to $500 per day.

Shipping starts at several hundred dollars and can cost up to $2,000, depending on the location of course.

Some dealers offer bundle deals that include the cost of the machine, training, shipping, and installation. Make sure you check out what deals they do before deciding on your purchase or seller.

How to choose a CNC router table

Table types

The most common types of CNC router tables include profile, vacuum, and adsorption block tables. A CNC router profile table is also known as a fixture table. This type of table directly presses the workpiece with a pressing plate screw, and is suitable for cutting, hollowing, and other processes, since as long as the air can escape, vacuum adsorption cannot be absorbed. When buying a profile table, customers can also choose the model that best suits them, based on the above two factors. However, if you use a cutting tool with a relatively small diameter (below 4mm), because the gap is small, some can also be vacuum-adsorbed on the table.

The CNC router vacuum table has a density board and is made from wood fiber and glue under high pressure. There are ducts or gaps between the wood fiber layers and after plugging the sealing tape, a vacuum pump can be turned on to create a vacuum and hold the workpiece securely to the table. This saves time faffing about with vices or screws and is especially suitable for the mass production of wooden doors. Sometimes it may be necessary to put a thin MDF board on first. The MDF board is placed on the CNC router vacuum suction table to prevent the milling cutter from damaging the worktable. The pressure on the part closest to the density board is much lower than the atmospheric pressure on the other side, forming negative pressure, so the workpiece is held incredibly firmly and with no annoying screws or clamps in the way. For example, it’s the same principle as when two sheets of glass are stuck together and it’s difficult to separate them. Once the seal is no longer tight, there is no negative pressure, so the pressure on both sides of the workpiece plate is the same, and they become easy to separate.

Table Sizes

The most common CNC router table sizes include: 2′ x 2′, 2′ x 3′, 2′ x 4′, 4′ x 6′, 4′ x 8′, 5′ x 10′, and 6′ x 12′.

Which CNC router spindle should you choose?

The spindle is one of the most important components of a CNC router machine. The machine generally needs to be equipped with a high-performance spindle to fulfill its functions. The quality of the spindle directly affects the processing speed and accuracy of the CNC router machine, so choosing the right spindle is really important. So, this is what you need to check:

1. Judge whether the spindle is high quality, or looks cheap.

1.1. Does the spindle motor use high-precision bearings? If high-precision bearings aren’t used, the spindle motor will overheat after long-term high-speed rotation, which will affect the service life of the spindle motor.

1.2. Is the sound uniform and harmonious when rotating at different speeds, especially at high speeds?

1.3. Is the spindle under force in the radial direction? The main point of reference is whether it’s possible to cut harder materials at high speed. Some spindles can only cut harder materials at extremely low speeds, otherwise, the spindle performance will be poor, which will affect the spindle accuracy after some time, or even cause a malfunction.

1.4. If you want high processing efficiency, the processing speed must be fast, with a large knife cut. When processing solid wood materials, you’ll need a spindle motor with a power of 2.2KW or more.

1.5. Standard CNC machine spindle configurations vary according to the equipment specifications.

2. Choosing the right CNC router spindle according to different applications.

2.1. The object engraved by the advertised CNC router machine is a relatively soft material, so the spindle power only needs to be 1.5kw – 3.0kw. If you choose this type, you can achieve routing while saving on costs.

2.2. The power of CNC wood router spindle motors can be selected according to the hardness of the wood to be processed. However, generally around 2.2kw – 4.5kw, should do the job.

2.3. The spindle power of stone CNC machines is relatively higher, at around 4.5kw – 7.5kw, and a 5.5kw spindle motor is the most commonly used.

2.4. Foam CNC router spindle power should also be selected according to the hardness of the foam to be processed. Usually, 1.5kw – 2.2kw will meet customer needs.

2.5. Due to the relatively high hardness of metal CNC router machines, the spindle motor power is generally between 5.5kw – 9kw.

In other words, too powerful a spindle motor wastes electrical energy and increases the initial purchasing price. If the power is too low the routing power demand simply won’t be available. Therefore, choosing a suitable spindle motor power is imperative.

3. The relationship between the CNC router machine and the routing materials.

The greater the routing material hardness, the lower the spindle rotation speed. This is just common sense. Harder materials need to be ground slowly and if the rotation speed is too fast, the tool may be damaged. The higher the routing material viscosity, the higher the spindle used. This is mainly for soft metals or man-made materials.

The diameter of the tool used in CNC router machines is also an important factor in determining the spindle speed. The practical tool diameter is related to the processing material and processing line. The larger the tool diameter, the slower the spindle speed will be. Determining the spindle speed should be based on the spindle motor usage. When the spindle speed decreases, the motor output power is also reduced. If the output power drops to a certain level, it will affect the processing, which will adversely affect the tool life and the workpiece. So, when determining the spindle speed, make sure that the spindle motor has the right output power.

What are the different types of CNC router machines?

Let’s have a look at the 10 most common types of CNC router machines, according to different functions, axes, materials, and applications.

Type 1: Mini CNC routers for small businesses

Type 2: Hobby CNC routers for hobbyists

Type 3: Desktop CNC routers for home shops

Type 4: Industrial CNC routers for woodworking

Type 5: ATC CNC routers with an automatic tool changer

Type 6: Nesting CNC machines for cabinet making

Type 7: 4-Axis CNC routers with a rotary table

Type 8: 5-Axis CNC routers for 3D modeling

Type 9: Metal CNC routers for aluminum

Type 10: Foam CNC routers for EPS and Styrofoam

What software can be used for CNC router machines?

Type3

Type3 is an all-round CNC router software solution for woodworking graphic design requirements. It runs under the Microsoft Windows system, has the best graphic design software package, and is closely integrated with the processing process. From simple characters to complex pattern making, Type3 has powerful functions and the flexibility to solve all professional engraving problems. Type3 fits all your needs and is easy to learn and use. It’s an all-round software for creativity and engraving processing. Type3 can accurately calculate the three-dimensional tool path, optimize the machine processing path, generate the CNC routing path, and finally generate the CNC routing code. You can freely select a variety of tools and drills including cone, spherical, and cylindrical types for routing.

Ucancam

Ucancam is special software that integrates computer-aided design (CAD) and aided manufacturing (CAM). It’s widely used in lots of applications such as advertising, signage, gifts, decoration, art, wood processing, and molds, to name just a few.

Ucancam series software has powerful graphics design and editing functions, it supports coordinate input and can accurately draw graphics. It also provides functions such as batch copying, artistic transformation, dynamic cropping, and node editing to facilitate graphics editing and modification. Automatic and interactive nesting increases the utilization rate of materials and typesets quickly.

With fast and accurate three-dimensional tool path calculation the Ucancam post-machining program is convenient for setting the code requirements of different machines. It reduces damage to the tool or material and doesn’t leave knife marks on the cutting surface. Cycloid machining provides strong technical support for cutting hard stone, glass, and brittle materials. At the same time, a variety of machining methods including 3D, center lining, drilling, inlaying, edge and cornering, round carving, image carving, and image relief are available, depending on customer needs. In addition, processing simulation, simulation functions, and a convenient and fast machining results display reduce the machining trial process and therefore also reduce the machining costs.

ArtCAM

The ArtCAM software product series, produced by the UK company Delcam, provides a unique CAD modeling, and CNC and CAM processing solution. It is the preferred CAD/CAM software solution for complex three-dimensional relief design, jewelry design, and processing. It can quickly convert 2D ideas into 3D art products. The all-Chinese interface enables users to design and process 3D relief more conveniently, quickly, and flexibly. It is widely used in the fields of engraving production, mold manufacturing, jewelry production, packaging design, medal and coin manufacturing, and sign making.

The Delcam ArtCAM software series can convert plane data such as hand-drawn drafts, scanned files, photos, grayscale maps, CAD, and other files, into vivid and exquisite 3D relief digital models, as well as generating codes that can drive CNC machine tool operation. ArtCAM includes a wealth of modules that are fully functional, fast running, reliable, and extremely creative. By using Delcam ArtCAM generated relief models, a more complex relief model can be generated through Boolean operations such as union, intersection, difference, arbitrary combination, superposition, and splicing. Plus, you can render and process the designed relief. Users don’t need to spend time and money to create real models because they can intuitively see the real design results right there on the screen.

Alphacam

Alphacam is manufactured by Lycome of Coventry, UK, and is a powerful CAM software package. The CNC router software has powerful contour milling and an unlimited number of pocket machining tools that can automatically clean the remaining materials and customize the settings. Tool path and speed appear on all windows simultaneously for dynamic physical simulations.

Alphacam automatic nesting software is currently the mainstream software used in the cabinet door processing industry. Its big advantage is that a door type only needs to establish a processing model (tool path) once, and it can realize automatic nesting of any size without the need for re-drawing. Consequently, the efficiency is significantly improved compared with traditional software.

Cabinet Vision (CV)

Cabinet Vision is a 3D integrated cabinet custom design software compatible with Windows. It can easily realize accurate auxiliary design and professional graphic design in strict accordance with corporate design specifications. Dedicated to cabinets and wardrobes, easy to operate and powerful, Cabinet Vision can accurately assist in the establishment of walls, select and design corporate standard system product graphics, and synchronously generate floor plans, elevations, side views, three-dimensional renderings, and assembly exploded views. It can also automatically generate multiple rendering views and fully match the customer’s visual requirements. Furthermore, automatic generation of retail quotations and parts lists, automatic splitting, and design and splitting, only takes 30 minutes, with zero errors and strict compliance with industry standards.

Complete accurate cabinet and store design can be generated in real-time in-store, according to customer customized requirements, a variety of renderings, and retail lists. This then connects with the post-processing end of the factory, to place orders remotely while guiding the generating process.

Which controllers can be used for CNC router machines?

Mach3 CNC Controller

When running on a computer, Mach3 is an economical and powerful machine tool control system. It is the most popular CNC controller worldwide. Operating Mach3 requires a computer with at least a 1GHz processor and a 1024—768 pixel display. The Windows system can run fully in this configuration. Desktop computers are more applicable and economical than notebook computers. When the computer isn’t being used to control the machine tool, it can be used for other workshop tasks. Mach3 mainly transmits signals through the parallel port, but can also transmit through the serial port. The drive motors of each machine tool must be able to receive both step pulse signals and direct signals. All stepper motors, DC servo motors, and AC servo motors with digital encoders meet this requirement. It’s worth noting that if you want to control an old CNC machine tool with a servo system that uses a resolver to measure the tool position, then you’ll have to replace each axis with a new drive motor.

NC studio CNC Controller

The NC studio CNC controller originates from China. The CNC system can directly support G-code and PLT code formats as well as fine routing generated by MASTERCAM, UG, ArtCAM, CASMATE, AUTOCAD, CorelDraw, and other CAM/CAD software. In addition to manual, stepping, automatic, and machine origin return functions, NC studio also has unique functions such as simulation, dynamic display tracking, Z-axis automatic tool setting, breakpoint memory (program skip execution), and rotary axis processing. This system can be used with several 3D CNC routers and 3D CNC mills. It is suitable for all kinds of complex mold processing, advertising paraphernalia, cutting, and other industries.

Syntec CNC Controller

Syntec is a popular CNC control system developed by Taiwan Syntec Technology Co. Ltd. Taiwan Syntec is currently the most promising professional PC-based CNC controller brand which specializes in the R&D, manufacturing, sales, and service of PC-based CNC controllers. The Syntec system CNC router machine offers stable performance, convenient and flexible operation, dual-program support, three- and four-program displays, and machine coordinates. Program editing and process monitoring are performed separately, the coordinates of each axis group are displayed independently, and each axis group can be simulated at the same time to rotate the program coordinates. It’s easy to write the processing program, perform three-dimensional processing on an inclined surface, and execute milling, drilling, and tapping.

The system supports the Yaskawa bus communication control mode, which greatly reduces wiring costs and space requirements, and improves cost-effectiveness. The Yaskawa bus communication control method helps improve the wiring and expandability problems of traditional pulse-type general-purpose controllers so that the system is simpler, more expandable, and easier to assemble.

DSP Controller

The DSP controller is a handle control system that can run offline. It can be separated from the computer during the engraving process and can directly control the engraving machine. It benefits from handle operation, humanized design, large screen display, multi-language interface, easier operation, and more convenient maintenance. A unique intelligent prediction algorithm is adopted to give full play to the potential of the motor, realize high-speed continuous processing, synchronize curves and straight lines, and make the curves smoother.

The system has Super error correction, which can pre-check processing documents, prevent writing or design errors in processing documents, and prevent material placement beyond the processing range.

NK CNC Controller

The NK series control system is an economical all-in-one machine with high reliability and high cost performance. It has imported micro switches, the panel function keys can be configured, and the timing ports can be customized, providing parameter import and export, and simple and quick system backup functions. The terminal board on the back of the all-in-one machine provides the 24V power input port, USB port, handwheel port, brake input port, brake output port, analog output port, servo drive interface (X-axis, Y-axis, Z-axis) required by the system. It also houses 16 general-purpose input ports and 8 general-purpose relay output interfaces. The operation panel has an emergency stop button, power button, spindle override, and feed-rate override band switches.

What should you know before buying a CNC router machine?

Before investing in a CNC router machine, or any wood CNC machine, it’s a good idea to visit an existing user and get a firsthand account of the machine from someone who has actually used one. Try to visit on your own, without a salesperson around, so you get to really hear how it has worked out for them.

If you can’t find a shop that runs the CNC machine that you want to have a look at, you could watch a demonstration either in-person or online. This is the best way to understand how the CNC machine works, and you can see it complete a job from start to finish.

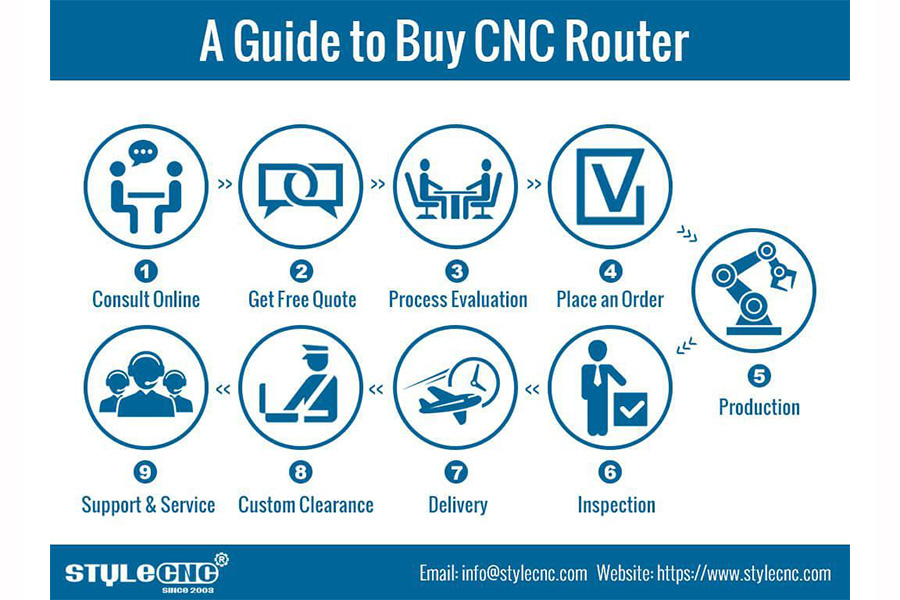

How to order a CNC router machine

1. Consultation: we will recommend the most suitable CNC router kits for you after assessing your requirements, such as the material you want to carve and the maximum size of the material (length x width x thickness).

2. Quotation: We will send you a free quote for your CNC router kits at affordable prices.

3. Process evaluation: Both sides carefully evaluate and discuss all the details of the order to prevent any misunderstanding.

4. Placing the order: If all is agreed, we will send you the PI (Proforma Invoice), and then sign a contract with you.

5. Production: We will arrange production as soon as we receive your signed sales contract and deposit. You’ll be kept up to date at every stage of the process.

6. Inspection: The production process will be subject to regular inspection and strict quality control. The completed CNC router machine will be tested to make sure it works perfectly before it leaves the factory.

7. Delivery: We will arrange delivery as per the terms in the contract after confirmation from the buyer.

8. Customs clearance: We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

9. After-sales support and service: We offer around-the-clock professional technical support and CNC router service by phone, email, Skype, or WhatsApp.

FAQs

How to setup, install, and debug a CNC router machine

Step 1. Setting up the machine frame.

1.1. Open the packing box and check whether the machine appears intact.

1.2. Count the physical parts according to the packing list.

1.3. Steadily place the CNC router machine on the base with its four feet down.

1.4. Adjust the feet to ensure the machine’s working surface is level.

1.5. Remove part of the outer cover and use a clean silk cloth and kerosene (or gasoline) to clean off the anti-rust oil on the lead screw and guide rail, removing any lubricating oil and dirt.

1.6. Add lubricating oil to the motion mechanism parts such as the lead screw and the guide rail.

1.7. Set up the outer cover while being careful not to collide with the moving parts.

1.8. Ground the machine frame well.

Step 2. Install the CNC router accessories.

2.1. Install the spindle motor cooling water tank, connect the tank with the spindle motor cooling pipe and add cooling water to the water tank, which should ideally be soft water.

2.2. Install the workpiece cooling system, connect the coolant tank to the water outlet of the bed diversion groove with a water pipe, and connect the upper water pipe. Add the specified workpiece coolant to the workpiece cooling box.

2.3. Install the tool setting instrument and connect and lock the tool setting instrument signal line with the machine tool setting instrument interface.

Step 3. Set up the electrical control cabinet.

3.1. Ground the electrical control cabinet well.

3.2. Connect and lock each machine tool input interface with the corresponding electrical control cabinet output interface with a control cable.

3.3. Connect the electrical control cabinet computer input control interface to the control computer with a control cable, and secure it with screws.

3.4. Connect and lock the interface between the operation keyboard and the electrical control cabinet with a control cable.

3.5. Turn off the electrical control cabinet power switch and connect the power socket to a 220V, 50HZ power supply.

Step 4. Install the CNC control system and software.

4.1. Turn on the control computer.

4.2. Install the attached CNC router machine control system.

Step 5. Equipment debugging and trial operation.

5.1. After checking that all the signal cables are connected correctly, and the required grounding is satisfactory, turn on the electrical control cabinet power switch and warm it up for 10 minutes.

5.2. Operate the operating keyboard to check whether the machine tool status and the movement are normal.

5.3. Run the idling test and add lubricating oil to the movement mechanism.

How to use a CNC router machine

1. Set the design and typesetting according to requirements. After correctly calculating the path, save the generated tool path as a different CNC router file.

2. After checking that the path is correct, open the path file in the CNC control system (preview available).

3. Fix the material and define the work origin. Turn on the spindle motor and adjust the parameters correctly.

4. Turn on the power and operate the machine.

The power indicator light will illuminate after turning on the power switch. The machine will perform a reset and self-check operation, the X-, Y-, and Z-axes return to the zero point, and then run to their initial standby positions (the initial origin of the machine). Use the controller to align the X-, Y-, and Z-axes with the starting point (processing origin) of the routing work. Select the required spindle rotation speed and feed speed to put the CNC machine into a working pause state. Transfer the edited file to the CNC router machine to automatically complete the routing design work.

How to maintain a CNC router machine

- Remove the dust in the electrical box regularly (according to the usage), and check whether the wiring terminals and component screws are tight to ensure the safe and reliable use of the circuit.

- After each use, be sure to clean up any dust and debris on the machine platform and transmission system, otherwise a lot of dust and impurities will enter the screw, guide rail, and bearing. The rotation resistance of the lead screw and the bearing is large, which can lead to jumping and dislocation when the engraving speed is slightly faster. Make sure the transmission system (X-, Y-, Z-axis) is lubricated and oiled regularly (at least weekly).

- It is recommended that the CNC router machine is not run continuously for more than 10 hours per day.

- The water pump and spindle are mutually interrelated. The circulating water must be replaced to keep the water clean and prevent the pump water outlet from becoming blocked. This will also prevent the water-cooled spindle from overheating and causing component damage and ensures the normal operation of the water pump. Never allow the water-cooled spindle to run without sufficient water.

- If the machine is not used for a long time, it should still be lubricated regularly (weekly) and run empty to ensure the transmission system’s flexibility.

Summary

After receiving your CNC router machine the technician will usually help to unpack and inspect the machine. After switching it on, you should carefully check whether anything appears to have been damaged during transportation. If all is fine, check all attachments for the machine configuration according to the contract are present using the manual. The technicians will install the machine including the hardware installation, removal of any fixed parts, and connection to the power supply. The software, computer configuration, and any optional CNC router software will also be installed. Following that, a test drawing file provided by the manufacturer will be used to test the machine. If the test is completed correctly, the delivery and acceptance of the machine are completed.

CNC operators are required to have a technical secondary school education qualification or above and have a proficient computer operation foundation. During the training process, they become proficient at choosing different speeds for different materials and using different CNC router tools. This often requires extensive experience and their expertise helps to extend the life of the CNC router machines and tools.

Source from stylecnc.com

Disclaimer: The information set forth above is provided by stylecnc independentiy of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller andproducts.