Warehouse heaters are needed to create a suitable working environment and protect products from the adverse effects of cold temperatures. The general requirement is for a reliable and simple system that works for years without any trouble. That said, heating a warehouse isn’t as easy as some think. It isn’t like flipping a switch on the heater, like in residential spaces. There are many factors to consider when figuring out how to heat a warehouse.

Nowadays, the key objective of most warehouse owners is to get a system with simple controls. It must produce the desired heat levels and consume minimum energy. This informative article covers the top warehouse heating systems and why this market is worth investing in.

Keep reading to uncover some unique insights!

Table of Contents

Global market size for warehouse heaters

4 popular warehouse heating solutions

Things to consider when choosing a heater for a warehouse

Final thoughts

Global market size for warehouse heaters

The purpose of warehouse heaters is to convert electric or steam energy stored in their system into thermal energy. This structure helps to heat the enclosed environments or containers. Given how storage facilities are growing, there is a clear signal that the demand for warehouse heaters will continue increasing.

The global industrial heater market is expected to grow steadily, with a yearly growth rate of 4.8% from 2025 to 2037. In 2024, the market was worth US$ 5.49 billion and is predicted to reach US$ 10.1 billion by 2037. Researchers state that the following factors will boost the demand for warehouse heaters:

- Increasing affordability and low price brackets of industrial heaters

- A reduction in energy consumption offered by these heaters reduces operational costs

- Solar and biomass energy production of heaters has introduced innovative products

- Improved safety protocols, digital controls, and automation features relieve warehouse owners from the worries

4 popular warehouse heating solutions

Warm air heating systems

Warm air heating is one of the most popular warehouse heating methods today. This system works by warming up the air inside a warehouse space. The warm air then heats the staff members and the products to ensure a smooth atmosphere for optimal functioning.

These heaters can be summarized into three main categories discussed below:

Direct fire unit heaters

These commercial heaters for warehouses are powered by oil or natural gas. The fuel burns in the heating system to produce warm air. Think of direct-fired unit heaters as similar to a gas grill. The flame directly contacts the air. The unit then pulls in air and heats it by passing it through a flame generated by gas.

These versatile warehouse heaters offer flexible placement options – they can hang from the high ceiling, stand on the floor, or be mounted on a wall. When choosing a location, evaluating the floor space is super important. Floor-standing direct-fired heaters take up valuable space that could be used for other warehouse operations. Also, consider the system’s maintenance requirements and ease of access for upkeep.

Indirect fired unit heaters

The functioning of these heaters is similar to that of home furnaces. The oil or gas used to power the heater creates a flame in the burn chamber. The flame heats the heat exchanger. Lastly, the air drawn into the heater goes over the exchanger, warming the air before pushing it out of the structure.

Indirect fired heaters run on natural gas or oil. Unlike direct-fired ones, the air they heat never touches the flame. These units typically need floor space for installation. However, these are considered the top warehouse heaters, so multiple installation options exist. For instance, they can also be mounted on the warehouse roof or placed outside, venting the warmed air inside.

Electric element unit heaters

The system of these electric heaters resembles the two mentioned above. In the first step, a coil or a heat exchanger is warmed with electric power. The air is then sucked inside the heater and passes above the exchanger. The air becomes warm and is tossed back into the warehouse.

These heaters operate solely on electricity, eliminating the need for oil or gas hookups. Many warehouse managers install electric heater units on the high ceilings to save valuable floor space.

Radiant heating system

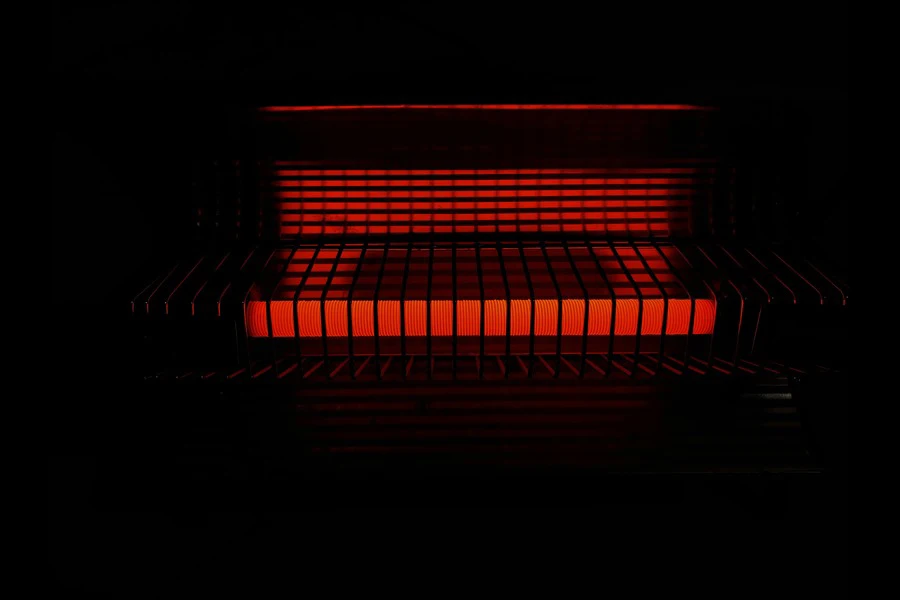

This relatively new heating method has been installed in selected warehouse structures. They function by using suspended tubes or plaque heaters that emit infrared radiation. Instead of warming the air, these heaters directly heat surfaces they encounter, including equipment, products, and staff members.

Typically, these heaters are hung from the warehouse ceiling to maximize their effectiveness. This allows the infrared radiation to spread downwards in a triangular pattern. It resembles how a desk lamp illuminates a larger area when held higher. Radiant heating works on the same principle, providing a wide spread of heat in a downward and outward direction.

These commercial space heaters for warehouses provide many unique benefits when installed alone. They can sometimes be combined to create a suitable warehouse heating system. When owners thoroughly know how warehouse heaters operate, they can better determine which ones suit different warehouse zones.

Things to consider when choosing a heater for a warehouse

Selecting the right heating solution in the first go is important to keep costly repairs or exchanges at bay. Let’s take a look at some of the most vital factors to consider when investing in heaters for a commercial space:

Racks

Racks are commonly used in warehouses to organize products and conserve floor space. They may block the heat distribution across the warehouse by blocking the air.

Remember that radiant heaters only heat what they directly face. If the infrared heat can’t reach areas blocked by racks or other objects, those areas won’t be warmed. Warm air heating might be a better choice in warehouses with extensive racking. These commercial heaters can heat the air around the racks, which infrared heating systems might struggle with.

Heat distribution

Even heat distribution is a vital factor when selecting a warehouse heating system. Heat moves through the air. But, warehouse obstacles like racks or shelves can disrupt airflow, leading to uneven heating. Uneven heat distribution negatively impacts both products and employees. To prevent this, position the heater to promote even heat circulation throughout the entire warehouse despite the racks.

Floor space

The reason why racks are used is to conserve floor space. The same rule applies for heaters. Most warehouse owners don’t prefer a heating structure that takes broader floor space. They usually opt for heaters mounted on the walls or ceilings or installed on floors underneath.

Heating warehouses require a lot of planning. Since these heaters are more expensive than the standard residential heaters, businesses should carefully monitor the market. They need to invest in solutions that are pocket-friendly, allow even heat distribution, and don’t cover a lot of space. An ideal heater withstands the sands of time and keeps functioning at its maximum potential for years.

Final thoughts

In 2025, the demand for warehouse heaters is expected to grow. Globalization and the expanding e-commerce sphere are the main reasons why there are more storage facilities now than ever. So, whether your customers belong to the e-commerce landscape or own regular brick-and-mortar stores, they may have varying warehouse heating requirements. And there is no better place than Alibaba.com to scan the trending warehouse heaters. This can be your first step to establishing a scaling business in the HVAC niche!