A good dough sheeter makes it easy for chefs to make pizzas, pasta, and pastry. The increased demand for dough sheeters from the food industry and industrial bakeries led to many players joining the market. The availability of many dough sheeters from different manufacturers does not mean choosing the right machine will be easy; instead, it is tricky to identify the ideal one.

Read on to find out the different types of dough sheeters available in the market and how to select suitable ones. This article will also discuss how dough sheeters work and the share and size of the dough sheeters market.

Table of Contents

Share and size of the dough sheeters market

How dough sheeters work

Types of dough sheeters

How to select suitable dough sheeters

Summary

Share and size of the dough sheeters market

Rising demand for processed food is a major factor driving the dough sheeters global sales. Generally, the dough sheeters market is segmented based on the type, application, and region. The types include bench style and tabletop sheeters. Based on the application, the specific categories are bakeries, restaurants, and others.

The global dough sheeters market size was estimated to be USD 1.09 billion in 2021. Data Intelo projected further growth up to 2030 with a compound annual growth rate (CAGR) of 3.3%. In addition to increasing demand for confectionery and bakery products, the growth will be attributed to rising disposable income and a growing population.

North America is among the regions expected to dominate the global dough sheeters market due to increased demand for baked foods. Europe will be the second-largest market, owing to the rising demand for pastries and bread. Asia Pacific will be the fastest-growing market due to the increasing number of pizzerias and bakeries. Some major companies associated with the production of dough sheeters include Ferneto, Omcan, Fritsch, and Cavallini.

How dough sheeters work

Dough sheeters pass lumps of dough between two rollers that flatten and stretch the dough to a consistent thickness. They are designed to process large quantities of dough consistently and quickly. The equipment is used to save time and effort in commercial dough-making processes.

Below is a step-by-step process of how dough sheeters work:

– An operator places a ball of dough on the infeed conveyor belt.

– The dough ball is then fed into the first set of rollers to be flattened into a rectangular shape.

– The flattened dough is passed through another series of rollers that systematically reduce its thickness.

– The rollers are adjusted to attain the desired thickness, and the dough is cut to the desired size for the final product.

– The finished dough sheet, ready for further processing, is passed onto the outfeed conveyor belt.

Types of dough sheeters

There are various dough sheeters, each designed for particular applications and types of dough. Below are the most common kinds of dough sheeters:

1. Manual dough sheeters

They are the simplest type of dough sheeters. They have two rollers that can be adjusted manually to alter the thickness of the dough. They are small-sized and suitable for small-scale operations like small bakeries and home baking.

2. Semi-automatic dough sheeters

Semi-automatic dough sheeters are quite similar to manual dough sheeters but are equipped with an automatic conveyor system that feeds the dough into rollers. They are faster, so they are suitable for medium-sized operations.

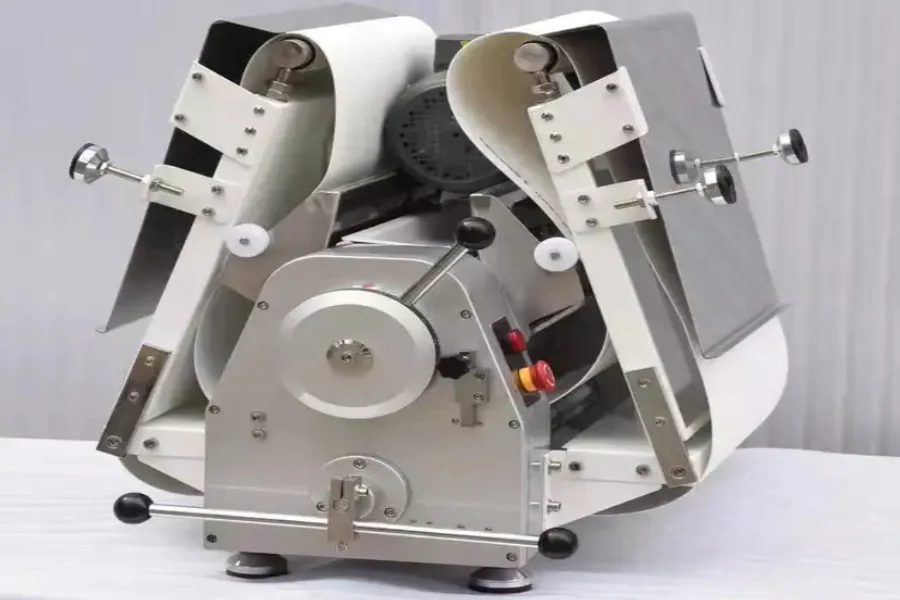

3. Automatic dough sheeters

These are the most advanced type of dough sheeters, as they are equipped with a fully automated system. They can produce uniform dough sheets quickly and efficiently. Therefore, they are used for large-scale operations like commercial bakeries.

4. Spiral dough sheeters

They are specialized dough sheeters designed to produce sensitive and delicate doughs like croissant dough, puff pastry, and Danish dough. They gently work by spiraling the dough via a series of rollers, which minimizes the risk of damaging the dough and preserves its delicate structure.

5. Lamination dough sheeters

These machines are designed to be used with laminated doughs like croissant dough. They layer the dough and fat together and then roll it out to a uniform thickness. This helps create flaky layers that are characteristic of these types of pastries.

How to select suitable dough sheeters

1. Budget

Buyers should note that the actual prices of dough sheeters depend on brand, features, and capacity. They should also consider their specific production needs and what fits within their budget.

With USD 500 or less, buyers could acquire manual or hand-crank dough sheeters, which are perfect for small bakeries. A budget range of USD 1,000-3,000 could acquire entry-level dough sheeters, which are more convenient and suited for small to medium-sized bakeries. Averagely, purchasing mid-range to high-end electric dough sheeters could cost over USD 3,000. They are designed for large bakeries and can handle high volumes of dough.

2. Capacity

The capacity of dough sheeters shows the amount of dough they can process in a certain amount of time. Buyers should consider the size of their kitchens or bakeries and the volume of dough they intend to process.

Low-capacity dough sheeters are suitable for small bakeries, home kitchens, and cafes. They averagely have a capacity of about 50 pounds of dough per hour. Mid-capacity dough sheeters have a capacity of about 100 pounds of dough per hour. These are perfect for medium-sized commercial kitchens and bakeries. High-capacity dough sheeters process over 100 pounds of dough per hour. They are designed for large bakeries and commercial kitchens that require high-volume dough processing.

3. Quality

Buyers have various factors to take into account regarding quality. It is critical to consider the manufacturers, materials, and additional features. There are brands that have a good reputation for producing high-quality dough sheeters. The durability of a dough sheeter depends on the materials used in its construction.

For instance, dough sheeters made from stainless steel are durable and should be maintained to ensure a longer service life. Also, buyers should opt for dough sheeters that are easy to use and have safety features like emergency stop buttons.

4. Adjustability

The level of adjustability of dough sheeters varies greatly. As such, buyers should always choose a dough sheeter based on their baking needs. Various dough sheeters offer a different range of dough thickness to accommodate different recipes and dough types.

There are dough sheeters with speed control features that allow buyers to monitor the speed of rollers in order to produce more precise results. Additionally, roller spacing, gap, and position will allow buyers to control thickness and distance during production.

5. Noise

When choosing dough sheeters based on noise level, buyers should consider the materials used in construction, the decibel rating, and the quality of construction. They should also check the noise reduction in the specific settings of the equipment.

Researching and checking out customer reviews is vital to acquire valuable information on the noise levels of various models. Some dough sheeters are made from noise-reducing and noise-absorbing materials like rubber.

6. Efficiency

Efficiency involves investing in high-quality and well-designed dough sheeters. These machines can process dough quickly and effectively with less or no requirement for maintenance or downtime.

Dough sheeters with production capacities that meet buyers’ needs are ideal. Speed control and dough handling allow buyers to process different dough types and thicknesses efficiently. Additionally, automation ensures ease of use, thus helping increase safety and efficiency.

Summary

In addition to the factors mentioned in the guide above, buyers should consider their specific needs and requirements. They should also look into the dough type they will be processing, the frequency, and the production volume. Investing in high-quality dough and well-designed sheeters can greatly pay off in terms of efficiency, performance, and longevity. Additionally, to acquire high-performance dough sheeters, visit Alibaba.com.