If you are in a production environment and cutting fine artwork or making metal parts, you will need a plasma cutting machine that will give you fast and clean cuts. In terms of metal fabrication, there are automatic CNC plasma tables that utilize computers to automate precise cutting in industrial manufacturing and there are portable handheld plasma cutters that are used in manual workshops. The question to consider, however, is which is the superior plasma cutter, and which is better suited to your purposes?

Plasma cutters are powerful machines capable of cutting through metal, with some even capable of cutting through thick shards like a knife through butter.

A plasma cutter is an essential piece of equipment for many welders. Strangely, however, it does the exact opposite of a welding machine as instead of fusing pieces of metal, a plasma cutting machine tears them apart. This is necessary as at some point during a welding project, it will become necessary to cut away the unwanted parts or shape the metal in a certain way.

Like everything in the welding industry, plasma cutters are constantly evolving, with more powerful metal-cutting machines being manufactured to cut thicker metals, and automation being added. It is clear that since welding is a dangerous process, robots or machines utilizing CNC automation are safer than actual humans, but what are the advantages and disadvantages of such a machine?

There are workers for and against automatic cutting and both arguments have their positive aspects, but whether CNC (robot) will replace manual welding remains to be seen.

Let’s understand these two cutting tools in terms of their working principle, performance features, uses, and pros and cons.

Table of Contents

The portable hand-held plasma cutter

The CNC plasma table and robotic plasma cutter

Comparison of the hand-held vs. CNC plasma cutters

Price and cost

Selection

The portable hand-held plasma cutter

A handheld plasma cutter is a compact and lightweight structure that can be carried to any job site, whether indoors or out. When using the portable hand-held plasma cutter, simply plug in the compressed air, grab the torch, and start cutting sheet metal, tubing, or profiles in seconds.

Principles of the hand-held portable plasma cutter

The two main components of a hand-held plasma cutting machine are the torch and chassis. An electric arc is generated between the nozzle (anode) and the electrode (cathode) inside the torch which ionizes the moisture in between to achieve a plasma state. Following this, the ionized steam is ejected out of the nozzle in the form of a plasma beam by the internal pressure, which then performs the cutting, welding, and other forms of heat treatment on the metal.

Features of the hand-held portable plasma cutter

Ultimate portability

Thanks to the ultimate portability of the cutter, the internal air compressor is able to operate in environments where external compressed air is not available.

Continuous output control

The continuous output control focuses the arc for different material thicknesses.

Touch-start system

The touch-start system starts the plasma arc without the need for high frequencies.

Fast ignition

Fast ignition quickly cuts through gaps, even when used in expanded metal.

Front panel purge controls

The front panel purge controls allow for an easy setting of the airflow rates without activating the plasma arc.

Front panel purge control

The front panel purge control system allows for the easy setting of the airflow rate without starting the plasma arc.

Cold operation and the long life of consumables

Thanks to its cold operation and the long life of its consumables, the new electrode and nozzle design can save you money during long operating hours.

Pros

The hand-held, portable plasma cutter adopts high-frequency inverter technology and presents the advantages of being compact, lightweight, and small in size, with high-frequency arc ignition, easy arc ignition, and high load duration. Additionally, by using cheap compressed air as the cutting air source, you can save money and improve efficiency compared to when using a flame-cutting machine. The cutting current (digital display) is continuously adjustable, accurate, and intuitive; and the fan is intelligently controlled to save on energy and electricity, while also reducing the failure rate of the fan.

The hand-held, portable plasma cutter is suitable for long-term, heavy-duty use. Moreover, it is not only suitable for hand-held cutting but also for automatic cutting systems such as CNC and robots. Finally, another aspect to consider is the fact that it has analog and digital interfaces to meet the communication needs of most automatic welding equipment.

Cons

The plasma arc presents an unstable phenomenon that can lead to defects, such as uneven cuts and tumor buildup. Additionally, it can lead to a reduction in the life of related components.

The bevel angle on one side of the cutting surface is large and presents poor verticality.

During the cutting process, more cutting residues are produced on the cutting surface. Due to this, the slag must be ground after cutting, as otherwise, it will affect the quality of the process, which in turn will increase labor costs.

Plasma cutting has a large heat-affected area and a wide cutting seam, and since metal is deformed by heat, it is not suitable for cutting thin metals.

The CNC plasma table and robotic plasma cutter

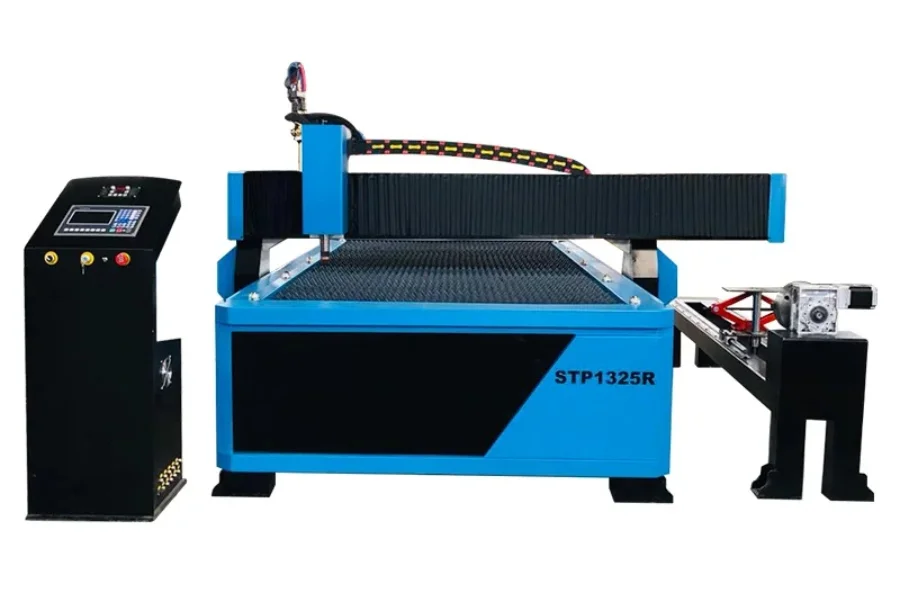

The CNC plasma table is an efficient, high-precision, and high-reliability piece of cutting equipment which is combined with precision mechanical transmission and thermal cutting technology. Its human-machine interface simplifies operations to make them more convenient. Thanks to this, it can quickly and accurately cut various complex shapes of plates, making it especially suitable for the automatic cutting of metals. It also offers a smart and easy-to-use integrated modular design.

Principles of a CNC plasma table and robotic plasma cutter

The CNC plasma table is combined with a simple and easy-to-use CNC controller, which ionizes the high-speed airflow ejected from the nozzle at high temperature to form a conductor. Once the current passes, the conductive gas forms a high-temperature plasma arc, the heat of which causes the metal at the incision of the part to partially melt (and evaporate). Following this, the power of the high-speed plasma gas flow is used to remove the molten metal to form a processing method.

When it works, a compressed gas such as nitrogen, argon, or oxygen is sent through a narrow tube and a negative electrode is placed in the middle of the tube. When this negative electrode is powered and the nozzle mouth contacts the metal, a conductive loop is formed and a high-energy electric spark is generated between the electrode and the metal. Here, as the inert gas flows through the tubes, the spark heats the gas until it reaches the fourth state of matter. This reaction process produces a stream of high-temperature and high-speed plasma, which can quickly turn metal into molten slag.

The plasma itself has a current flowing through it, and as long as the electrodes are powered and the plasma maintains contact with the metal, the cycle of arcing will remain continuous. To ensure this contact with the metal while avoiding the damage caused by oxidation and other as-yet-unknown properties, the cutting machine nozzle is equipped with another set of pipes that continuously emit shielding gas to protect the cutting area. Thanks to the pressure of this shielding gas, the radius of the columnar plasma can be effectively controlled.

Features of a CNC plasma table and robotic plasma cutter

The CNC plasma table’s beam adopts a box welding structure while the heat treatment eliminates the stress. This cutter is lightweight and has the characteristics of good rigidity, no deformation, high precision, and small inertia.

The two ends of the longitudinal drive frame (end frame) on this cutter are equipped with horizontal guide wheels, which can adjust the compression degree of the eccentric wheel at the bottom of the drive frame to the guide rail, meaning that the whole machine can maintain a stable guide during movement. It is also equipped with a dust collector to limit the debris accumulated on the surface of the guide rail.

Both the vertical and horizontal drives are driven by a precision rack and pinion. The horizontal guide rail adopts a precision cold-drawn guide plate, the longitudinal guide rail is made of precision-processed rail (heavy rail), and the reduction device adopts an imported precision gear reducer. The back-lash is eliminated to ensure movement accuracy and stability.

The CNC plasma table is cost-effective and easy to operate. It adopts an integrated cutting table and receiving hopper. Moreover, if required it can adopt a semi-dry dust removal method or an optional dust removal system to reduce the smoke and harmful gases generated by the machine during cutting.

This plasma cutter offers an advanced computer-controlled system, with fully offline work, a humanized design, and simple and fast operating modes. According to the operation process, the bottom of the screen of the CNC system provides various operation functions on clear displays, and the training-free mode is provided.

The cutter adopts the guide-and-prompt maintenance method. This means the fault indications are shown on the screen of the numerical control system and all fault phenomena are clear at a glance. The maintenance of the whole machine is convenient and fast and done according to the fault instructions.

To simplify the compilation procedure, the operator compiles a graphic and then selects the cutting quantity and cutting arrangement direction to create continuous and automatic cutting and overall compilation, thereby reducing the workload for the designers.

The software adopts unit modular production technology, which improves the stability and operation sensitivity of the equipment and reduces later maintenance costs.

The common accessories and parts of the machine can also be purchased on the market, thereby reducing the cost for customers.

The CNC underwater plasma cutter table is equipped with a waterbed for underwater cutting, which greatly reduces environmental pollution such as smoke, arc light, harmful gases, and noise. This means a good environmental protection effect.

Pros

Good cutting quality and low labor cost

The plasma-cutting machine uses non-contact processing and does not damage the workpiece. The cut product has no extrusion deformation and the processed product is of good quality with no burr and no requirement for manual re-grinding. This saves on unnecessary processing procedures and optimizes labor and strength.

Save on mold investment and reduce production costs

Plasma-cutting machines can directly create various metal workpieces without molds or mold consumption and without the need to repair or replace molds. This can also save on the number of molds used, save on processing costs, and reduce production costs, making it especially suitable for the processing of large products.

High precision to effectively improve productivity

Automatic plasma cutting boasts high accuracy, efficiency, and flexibility, and can effectively process various complex parts. Automatic plasma cutting reduces the cutting time as it only needs to make a cutting graphic and import it into the control system, and then the size can be set for cutting.

Fast cutting speed and optimized working environment

As well as cutting quickly, automatic plasma cutting is stable when working, the noise is low, there is no dust, and it will not produce chemical substances that are harmful to the human body and the environment. This investment offers reduced pollution, promotes the optimization of the working environment, and complies with the tide of environmental protection.

Low maintenance costs and cost performance

The costs involved in the maintenance of mechanical products are very high, but due to its stable performance, the plasma cutter is durable and can work continuously without being easily damaged. This means the plasma cutter has great advantages in terms of later maintenance costs.

Cons

Cutting thick metal requires a high power supply, which can be expensive when buying a laser-cutting machine with a fiber laser source. Operating and maintaining automated equipment also involves potential hazards and operators should exercise caution to prevent injury.

If an operator’s limbs touch the moving machine, they can become entangled and injured. However, operators can easily keep their hands and feet away from the moving machine as the computer’s numerically controlled system can be used to control the cutter from the front panel keypad or remote interface. Despite this, when operating the machine, do not wear loose clothing or clothing with cords to prevent them from becoming entangled in the machine.

The plasma CNC cutter has the threat of giving off a high-voltage electric shock which can injure and kill people. Thus, it must be installed in accordance with the steps and requirements specified by the manufacturer.

Uses

Typically, handheld plasma cutters are used by hobbyists while CNC plasma cutting tables and plasma robots are used for commercial use and industrial manufacturing. However, both of these can be used for automotive engine protection panels, chassis cabinets, garden iron, pressure vessels, chemical machinery, ventilation and refrigeration, security door manufacturing, machining, fan manufacturing, construction machinery, steel structures, boiler manufacturing, shipbuilding, petrochemical equipment, light industrial machinery, aerospace, pressure vessels and decoration, large sign manufacturing, and other industries.

All plasma cutters and robots can cut carbon steel (flame cutting), stainless steel, copper, aluminum (plasma cutting), aluminum sheets, galvanized sheets, white steel sheets, stainless steel, copper sheet, and other metal pipes, as well as being able to carry out cutting and blanking operations on profiles and sheets.

Comparison of the hand-held vs. CNC plasma cutters

Now that we know more about these two types of plasma-cutting machines, we can ask ourselves what their similarities and differences are. In the following section, we will compare 8 aspects so that you can make the right choice when deciding which one is suitable for your business.

Arc starting method

There are two types of plasma power supply, being contact arcing and non-contact (button) arcing. The hand-held plasma power supply counts with a contact arc starting method. The CNC plasma cutter, on the other hand, should use a non-contact arc starting method. To judge which arc starting mode the power supply belongs to, simply check the button on the hand torch. Generally, power supplies with a current greater than 100A are non-contact arc starting methods.

Power supply

The handheld plasma power supply has a strong interference with the numerical control system, while the influence of the computer-controlled plasma power supply is near inexistent. In severe cases, this can lead to a black screen appearing on the numerical control system.

Torch

The torch at the CNC plasma power supply is a straight gun, while the torch at the handheld plasma power supply is a curved handle gun.

Capability

Probably the most obvious difference between an automatic robotic plasma cutter and a manual cutter is the power each produces.

Manual plasma cutters are usually smaller devices that are lightweight and easy to carry but because they don’t have the capacity to generate that much heat, they can’t generate that much power.

Robotic plasma cutters, on the other hand, are stationary machines that generate a lot of heat, meaning the plasma streams they produce are really hot.

The capabilities of some CNC or robotic cutters simply cannot be measured manually.

CNC or robotics are used in industrial manufacturing where they cut through very thick metal sheets. In addition to the cutting, it can be very dangerous for humans to stand near such enormous heat. As a result, manual plasma cutters are better suited for smaller projects and people typically use them around the workshop for basic types of cutting or for thinner metals.

Portability

We have touched on the aspect of portability above. CNC plasma cutters are usually huge stationary machines that require the sheet metal to be cut in order for it to be fixed to the machine. On the other hand, manual plasma cutters are lightweight and portable, meaning they can be taken into the field for work anywhere they are needed. Additionally, they possess the advantage of being easily maneuverable into some tight places, which is difficult and in some cases impossible with an automatic plasma cutter.

Precision

There is another aspect to consider with regard to CNC cutting success. No one can cut as precisely with a manual plasma cutter as they can with a CNC machine, as these are highly programmed and guided using state-of-the-art software and a human cannot cut as concisely as a machine. Therefore, manual plasma cutters can work without regard to the precision of the product.

In some jobs, precision is so important that it is possible to accidentally ruin the final product if this fails. Therefore, it is crucial that the plasma cutter work properly.

Price and cost

If you’re a hobbyist, you’ll definitely be looking for a smaller handheld plasma cutter. The really good ones sell for about $1000 each, which is a price that is affordable to a good welder who does work in the garage or who just enjoys working on DIY projects.

CNC plasma cutters, on the other hand, are really expensive, with a cost upwards of $8,000 per unit. Just armed with this knowledge, it is safe to say that robots are only useful for big companies in need of automatons. Additionally, small companies cannot always afford an expensive CNC or robotic cutter and so they have to stick with a manual cutter.

Selection

So, what conclusions can be drawn from this article?

Essentially, a handheld plasma cutter is a good choice for simple jobs. It’s powerful enough to cut thinner or medium-thickness metal sheets and is suitable for any type of project in the garage or around the house. Also, it is very useful for fieldwork.

When it comes to automatic CNC plasma cutters, they are made for a tougher job. Industries that really need precision and functionality will go to any lengths to buy one of these.

In the end, the choice will come down to performance and accuracy, and affordability and flexibility.

Source from stylecnc.com

Disclaimer: The information set forth above is provided by stylecnc independently of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller and products.