If you’re new to 3D printing, you’re in for an exciting journey into additive manufacturing. With 3D printing, you’re not just creating objects; you’re unlocking a world of opportunities and redefining how we design, prototype, and manufacture. From speeding up product development cycles to customizing products to fit individual needs, the benefits of 3D printing are as vast and varied as imagination itself.

Here, we’ll explore 3D printing, its benefits, and the different types of 3D printers available to help you get started.

Table of Contents

What is 3D printing?

Market for 3D printers

Benefits of 3D printing

Types of 3D printers

Materials used in 3D printing

Final thoughts

What is 3D printing?

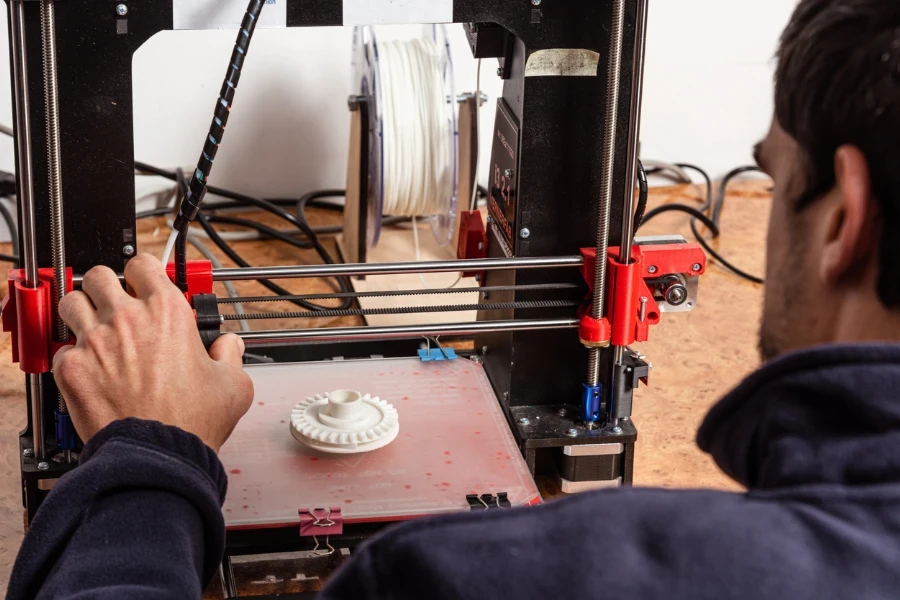

3D printing, also known as additive manufacturing, is a revolutionary technology that allows you to create three-dimensional objects layer by layer from a digital model. Unlike traditional subtractive manufacturing methods, where material is removed from a solid block to create a shape, 3D printing builds objects layer by layer, adding material only where needed. This process enables the production of complex geometries and customized designs with precision and efficiency.

Market for 3D printers

According to Grandview Research, the global 3D printing market was valued at over US $20 billion in 2023 and is projected to grow at a compound growth rate (CAGR) of 23.5% between 2024 and 2030. In 2023, North America emerged as the dominant force, commanding over 33% of global revenue, signaling a robust foothold in this transformative technology.

Benefits of 3D printing

The numerous benefits make 3D printing so appealing in many industries, which is why we continue to see businesses adopting 3D printing as part of their regular business processes.

Here are some of the major benefits:

- Design freedom: 3D printing makes it possible to create intricate and complex shapes that would be challenging or even impossible to achieve using traditional manufacturing methods.

- Rapid prototyping: With 3D printing, you can quickly iterate on designs and produce prototypes for testing and validation, reducing time-to-market and development costs.

- Customization: 3D printing enables customization and personalization of products, catering to individual preferences and unique requirements.

- Cost-efficiency: Additive manufacturing can be more cost-effective for low-volume production runs, as it eliminates the need for expensive tooling and setup.

- Reduced waste: 3D printing minimizes waste compared to traditional manufacturing processes by using only the material necessary to build the object.

- On-demand manufacturing: 3D printing allows you to produce objects on demand, eliminating the need for large inventories and storage space.

- Accessibility: 3D printers are becoming more affordable and user-friendly, making the technology accessible to individuals, hobbyists, and small businesses.

Types of 3D printers

Several types of 3D printers are available, each utilizing different technologies and materials.

Here are some of the most common types:

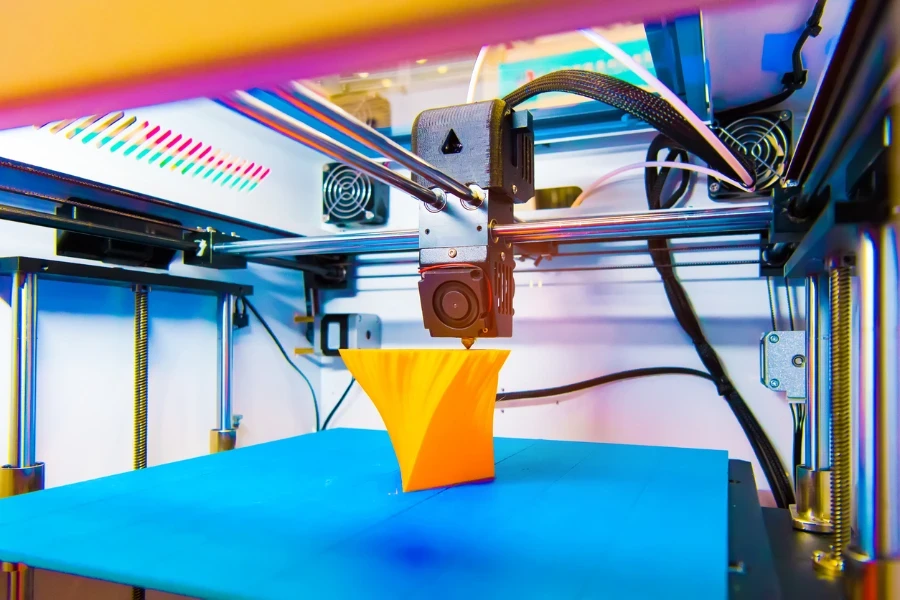

- Fused deposition modeling (FDM): FDM printers extrude thermoplastic filament through a heated nozzle, building layers to create the final object. This is one of the most popular and affordable types of 3D printing technology.

- Stereolithography (SLA): SLA printers use a liquid resin cured by ultraviolet (UV) light to create objects layer by layer. This technology offers high resolution and smooth surface finishes, making it ideal for detailed prototypes and models.

- Selective laser sintering (SLS): SLS printers use a high-powered laser to selectively sinter powdered material, such as plastics or metals, to create objects. This method enables the production of durable and functional parts with complex geometries.

- Direct metal laser sintering (DMLS): DMLS printers use a high-powered laser to selectively fuse metal powder, layer by layer, to create metal parts. This additive manufacturing technology can produce complex geometries with excellent mechanical properties, making it suitable for aerospace, medical, and industrial applications.

- Electron beam melting (EBM): EBM printers use an electron beam to melt and fuse metal powder to build layers and create metal parts. This technology offers high accuracy and minimal material waste and is commonly used in the aerospace, automotive, and orthopedic industries to produce complex, high-performance components.

- Inkjet 3D printing: Inkjet 3D printing employs an inkjet printhead to deposit droplets of material onto a build platform, which is then cured or solidified to form layers. This technology can print with a wide range of materials, including polymers, ceramics, and metals, and is used in various industries for prototyping, production, and customization.

- Digital light processing (DLP): Similar to SLA technology, DLP printers use a digital light projector to cure layers of liquid resin. However, DLP printers typically cure entire layers simultaneously, resulting in faster print times.

According to Grandview Research, the stereolithography (SLA) segment led the market and accounted for over 10% of global revenue in 2023. Fused deposition modeling (FDM) accounted for a considerable revenue share in 2023, owing to the extensive adoption of the technology across various 3DP processes. The DLP, EBM, inkjet printing, and DMLS segments are expected to witness growing adoption between 2024 and 2030 as these technologies are applicable in specialized additive manufacturing processes.

Each type of 3D printer has advantages and limitations, so it’s important to consider your needs and requirements when choosing the right technology for your projects.

Materials used in 3D printing

In 3D printing, the choice of materials plays a crucial role in determining the properties and characteristics of the final printed object. Here’s an overview of some common materials used in 3D printing:

Plastics

- ABS (acrylonitrile butadiene styrene): Known for its strength, durability, and impact resistance, ABS is a popular choice for functional prototypes and end-use parts.

- PLA (polylactic acid): PLA is a biodegradable and environmentally friendly thermoplastic derived from renewable resources such as corn starch or sugarcane. Due to its ease of printing and vibrant colors, it’s widely used for prototyping, hobbyist projects, and educational purposes.

- PETG (polyethylene terephthalate glycol): PETG combines the strength and durability of ABS with the ease of printing of PLA, making it suitable for a wide range of applications, including mechanical parts, containers, and displays.

Resins

- Standard resins: Standard resins are commonly used in stereolithography (SLA) and digital light processing (DLP) 3D printing technologies. They offer high-resolution and smooth surface finishes and are ideal for detailed models, jewelry, and dental applications.

- Engineering resins: Engineering resins can withstand high temperatures, harsh environments, and mechanical stress. Examples include tough, flexible, and high-temperature resins suitable for prototyping functional parts, molds, and tooling.

- Castable resins: Castable resins are designed for investment casting applications, allowing users to create detailed patterns for jewelry, dental, and manufacturing molds that can be cast in metal alloys.

Metals

- Stainless steel: Stainless steel is widely used in metal 3D printing for its strength, corrosion resistance, and versatility. It’s suitable for producing durable and functional parts for aerospace, automotive, and medical applications.

- Titanium: Titanium offers a unique combination of strength, lightweight, and biocompatibility, making it ideal for aerospace, medical implants, and high-performance engineering applications.

- Aluminum: Aluminum is valued for its lightweight, thermal conductivity, and recyclability. It’s commonly used in the aerospace, automotive, and consumer electronics industries to produce lightweight components and heat sinks.

Composites

- Carbon fiber: Carbon fiber composites combine carbon fiber’s lightweight and high-strength properties with the versatility of 3D printing. They’re used in aerospace, automotive, and sporting goods to produce lightweight and durable parts with enhanced mechanical properties.

- Glass fiber: Glass fiber composites offer strength, stiffness, and thermal stability, making them suitable for structural applications, such as automotive parts, sporting equipment, and industrial components.

Properties and applications of 3D printing materials

Each material used in 3D printing has unique properties and applications, making it essential to choose the right material for your specific project requirements. Here are some of the most common properties and applications:

- Strength and durability: Some materials, such as ABS, PETG, and engineering resins, offer high strength and durability, making them suitable for functional prototypes, mechanical parts, and end-use products.

- Flexibility and elasticity: Flexible and elastomeric materials, such as TPU (thermoplastic polyurethane), are ideal for producing flexible parts, gaskets, and wearable devices.

- Heat resistance: Materials with high heat resistance, such as high-temperature resins and metal alloys, are suitable for applications exposed to elevated temperatures, such as engine components, molds, and tooling.

- Biocompatibility: Biocompatible materials, including certain resins and metals, are used in medical and dental applications, such as surgical guides, dental models, and orthopedic implants.

Understanding the properties and applications of different 3D printing materials is essential for selecting suitable materials for projects and achieving desired outcomes in performance, aesthetics, and functionality.

Final thoughts

3D printing is a groundbreaking technology that offers numerous benefits, including design freedom, rapid prototyping, customization, and cost-efficiency. By understanding the different types of 3D printers available and their capabilities, you can unlock endless possibilities for innovation and creativity in your projects.

For business owners looking to capitalize on the growing demand for 3D printers, the next step is to delve deeper into the realm of selling 3D printers. Whether you’re considering adding 3D printers to your product lineup or launching a new venture focused on 3D printing technology, there are many factors to consider and strategies to implement for success.

To learn more about selling 3D printers, check out the next blog in this series. In this guide, we’ll explore everything you need to know to enter the exciting world of 3D printing sales.