The chocolate-making machine is designed to help many industry leaders—from owners of small businesses to those of big plants—complete the detailed process that starts with cocoa beans and concludes with chocolate molding. It is important to shoppers that these machines are diligent, versatile, and cost-effective. Read below and learn about a few valuable tips on today’s trends for chocolate-making machines.

Table of Contents

Bakery processing equipment: a market worth every dime

Chocolate-making machine trends

Key tips when choosing a chocolate-making machine

Final thoughts about chocolate-making machine trends

Bakery processing equipment: a market worth every dime

Many business owners need a way to keep up with growing business needs, and the baking industry has a few ways it can lend a helping hand. The global bakery processing equipment market size was valued at over $12.9 billion in 2020. More is sure to be in store for industry leaders relying on bakery processing equipment today with projections indicating a CAGR of 5.8% between 2021 and 2028.

As the lifestyle of the consumer continues to change, so does individual taste, compelling manufacturers of foods to elevate their respective products in the market. Advanced bakery processing equipment that can handle a wide variety of ingredients and perform several functions across the production line are highly favored.

When it comes to trending equipment, the chocolate-making machine is a highlight. From endurance and design to flexibility and ease of use, shoppers are keen on paying attention to these noteworthy trends in today’s market.

Chocolate-making machine trends

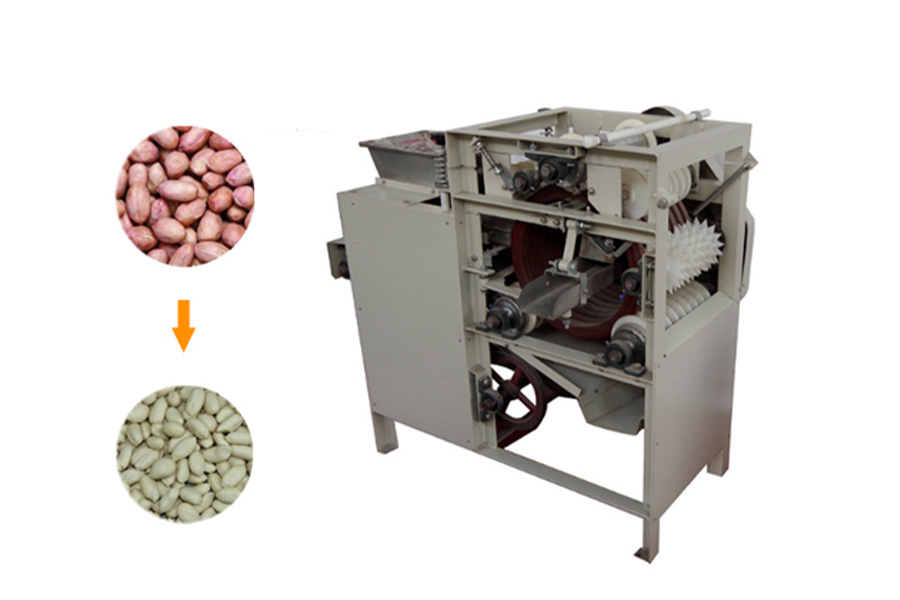

Cocoa bean peeling machine

One exciting trend to know when shopping for a chocolate-making machine is the function of cocoa bean peeling. Designed with great function, the cocoa bean peeling machine is perfect for peeling cocoa beans as well as coffee beans, the former of which can be processed into servable chocolate products. The steel-like makeup provides a strong foundation for this highly-automated machine to operate daily.

The cocoa bean peeling machine trend presents advantages such as a high-halving rate, low noise, and no pollution. Also, this machine contains a dust suction device that can remove the red skin of traveling cocoa beans, elevating the chocolate-making machine experience for business owners everywhere.

Cocoa grinding machine

Moving further along into the chocolate-making process, there is a valuable trend known as the cocoa grinding machine, and it is great for many reasons. Built with a few adjustable loading systems, control over the grinding of the cocoa bean is seamlessly reinforced. A tiny adjustable gap between the stator and rotor allows cocoa beans to pass and then prepares them for crushing and emulsifying.

So very multipurpose in its functioning, the cocoa grinding machine trend allows business owners to process other food items. This machine may be able to produce peanut butter, sesame paste, chili sauce, jam, and so much more. Thanks to the tilting feature, the cleaning process for the cocoa grinding machine is made simple, a handy feature for chocolate-making machine shoppers.

Chocolate refiner machine

As the chocolate-making process comes to a close, the chocolate refiner machine brings high performance front and center. Refining involves the final grinding of all particles in the liquid-like chocolate that is produced throughout this sophisticated chocolate-making process. After refining, an even and smooth texture is produced, making it hard to believe that the resulting chocolates were once beans that needed to be crushed first.

Due to the industrial design of the chocolate refiner machine, it is capable of sustaining heavy-duty production, which is encouraging for shoppers who value longevity in their equipment. The no-slip gear system reduces the risk of error during days and nights of continuous production.

Key tips when choosing a chocolate-making machine

Depending on what a business owner is looking for, the choice of a machine may differ from that of their competition. Ahead are a few tips an owner would benefit from when considering a chocolate-making machine for their business.

Shop-vac

Used for a very important step in the chocolate-making process, the shop-vac is responsible for what is called winnowing. This step refers to the separation of the roasted cacao bean from its thin shell or husk. This not only readies the bean for chocolate liquor transformation but also helps to ensure that the husk itself does not make it into the chocolate.

Cacao bean grinder

This feature grinds roasted and winnowed beans into a thick cacao paste. The sharp blades of the grinder are often associated with chopping and mixing pizza dough, and they are perfect for cacao beans that are ready to be ground.

Melanger

A melanger is required to execute two of the most important steps in the chocolate-making process—conching and refining. With the melanger’s help, the bitterness of the cacao paste is neutralized and the chocolate’s finished aroma is efficiently defined. Saving business owners everywhere a lot of money, the melanger and its two large, rotating stone wheels create an exceptionally smooth chocolate liquor, a key element in memorable truffles and chocolates.

Mold size

When it is time for the molding process, the chocolate-molding machine is perfect for the job. This device is great for producing chocolate in various shapes and sizes, and size matters a great deal when it comes to production capacity. The amount of chocolate that is being produced is dictated by the size of the molding machine. This is important information for shoppers who want to be able to sustain their current state of operations.

Production capacity

A chocolate-making machine’s production capacity can vary based on its classification. Large scale, medium scale, and small scale classifications are made based on the output of any given machine. Large-scale machines are more commonly operating out of businesses with higher production demands, achieving an average output of over 1000 kg per hour. For medium-scale machines, that number is closer to over 100 kg per hour, and then a maximum of 50 kg per hour corresponds to small-scale machines.

Key components

Due to the many different operations happening during the chocolate-making process, other machines need to be used. The tampering machine, for example, is designed to begin the heating process of the chocolate liquid, allowing chocolate makers to successfully crystalize the chocolate with a desirable consistency. The pump system is also key to the chocolate-making process, proving to be useful in how liquid ingredients travel and flow into the mixing unit.

Final thoughts about chocolate-making machine trends

There is no denying that thanks to the work of the cocoa bean peeling machine, cocoa grinding machine, and chocolate refiner machine, chocolate-making machines are items to watch this year. Owners in the food-processing business will typically spend the year in search of capable and crafty chocolate-making machines that shine in innovation, durability, flexibility, and operational execution.

As the desire for these chocolate-making machines continues to fill the online market, it is the perfect moment for wholesalers to know the trends and meet the growing demand.