Whether managing a high-volume bakery, running a wholesale operation, overseeing a round-the-clock food production line, or expanding into large-scale pastry manufacturing, the right machine is crucial for your operation’s success.

In this article, we’ll address the key considerations in selecting a machine, explain why investing in the appropriate equipment is critical for your business, and outline the essential features to look for.

Table of Contents

Perks of using cream paste filling machines

Types of cream paste filling machines

Top considerations when buying a cream paste filling machine

Summary

Perks of using cream paste filling machines

Here’s why businesses in food production may want to invest in a cream paste filling machine:

Increased production efficiency

Speed is everything when baking for a crowd. With a cream paste-filling machine, we can whip up batches of pastries quickly, filling them with precise amounts of cream. When those big orders roll in, we’ll be ready to tackle them confidently.

Improved product quality

Consistency is what keeps customers coming back for more. Nobody wants a pastry that’s skimpy on the filling in one bite and overflowing in the next. Cream paste-filling machines take the guesswork out of the equation. Every single pastry gets the same amount of cream, ensuring a delicious and consistent experience for the customers.

Labor cost savings

Sure, these machines come with a price tag upfront. But think of it this way: how many people to hire to keep up with that kind of output? Suddenly, the investment starts to make sense. Plus, machines don’t call in sick or need breaks for coffee. On top of that, they’re less likely to make mistakes that waste precious ingredients.

Enhanced hygiene standards

Cleanliness is a top priority in any kitchen, especially when dealing with pastries. These machines are designed to minimize the amount of contact your hands have with the filling, which reduces the chance of contamination.

They’re also built for easy cleaning, with smooth surfaces and parts that are easy to reach. This makes them a dream for health inspectors and keeps the reputation spotless.

Types of cream paste filling machines

Manual filling machines

These are the basic, no-frills workhorses—perfect for small bakeries or newcomers to the pastry game. Picture a giant syringe—control the lever, and out comes the cream. They’re cheap, simple to use, and give total control over each pastry’s filling. But the catch is the worker will be there all day if got a big order. Arms might give out before we finish, and keeping things consistent can be tricky.

Semi-automatic filling machine

This is where humans meet machines in perfect harmony. Load up the pastries, hit the button, and let the machine do its job. It’s faster and more consistent than doing it by hand, but people are still in charge.

These machines are the sweet spot for many mid-sized bakeries—they boost production without costing an arm and a leg. Most of all, you get speed, accuracy, and a bit of that artisanal touch all in one package.

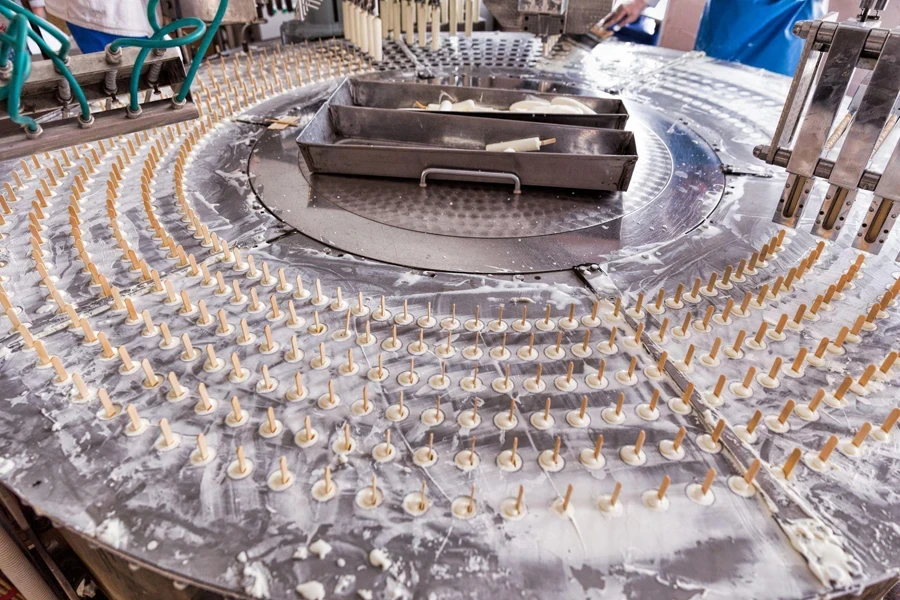

Fully automatic filling machines

Fully automatic filling machines are the pastry world’s equivalent of a factory assembly line. Load them up, punch in the settings, and watch them go. They’ll fill hundreds of pastries perfectly while you grab a coffee.

They’re fast, consistent, and can handle massive orders without breaking a sweat. Many come with fancy bells and whistles like programmable filling amounts or multiple nozzles for even faster work. The downside is they’re expensive and can be complex to operate.

Top considerations when buying a cream paste filling machine

Ease of cleaning and maintenance

Let’s face it—nobody likes cleaning, but it’s crucial in the food business. Stainless steel is the solid option here if you want machines that are easy to take apart and scrub down. They are tough, don’t rust, and wipe clean in a jiffy. Fewer moving parts mean less time spent with a wrench in hand.

Speed and efficiency

Time is money, folks. How fast the machine can pump out filled pastries should top your checklist. Manual machines are great for small batches, but if drowning in orders, semi-automatic or fully automatic machines are the way to go. Also, consider how quickly it can switch between different pastry sizes or cream types.

Accuracy and consistency

Don’t want to end up with a skimpy éclair or an overstuffed donut? Machines that nail the filling amount every single time are needed. Look for programmable settings that let us dial in the perfect amount.

Capacity and volume

Size matters when it comes to cream paste-filling machines. How much cream can it hold? How many pastries can it fill before needing a refill? A small bakery doesn’t need a massive cream paste filling machine. But businesses cranking out thousands of cream puffs daily want a machine that can keep up without constant babysitting.

Construction material

An ideal machine is built to last, not fall apart faster than a soggy croissant. Stainless steel is the gold standard—it’s tough, doesn’t rust, and stands up to daily wear and tear. Avoid anything that might flake off into food or can’t handle being cleaned regularly.

Summary

When seeking for a cream paste filling machine, put cleanliness and easy upkeep at the top of the list. Machines that are easy to sanitize will keep those health inspectors happy and the kitchen running smoothly. Think about speed, too—how fast can these machines churn out filled pastries? This will make or break the overall production goals.