Both laser cutting and wire EDM are ideal for precision cutting processes. The two methods cut and shape materials by using fine-point thermal technology. Just because the two methods do the same job and use the same technology it does not mean they are exactly the same. There are many differences between laser cutting and wire EDM which you need to know before deciding on which machine to invest in.

In this article, we are going to look not only at their differences but also at their pros, cons, and applications.

Table of Contents

What is laser cutting?

What is wire EDM?

The differences between laser cutting and wire EDM

Conclusion

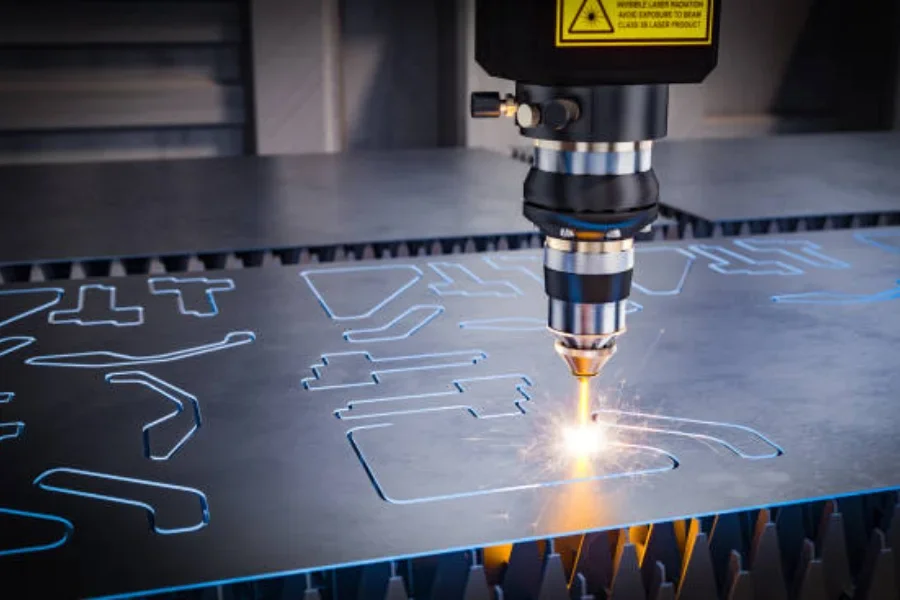

What is laser cutting?

Laser cutting is a fabrication method that involves cutting materials into the desired patterns, designs, and forms using a thin and focused laser beam. The beam from the laser cutting machine heats, melts, and vaporizes the material. This thermal-based and non-contact cutting process is applied to various materials, including wood, plastic, glass, metal, and gemstones. If combined with CNC technology, laser cutting can process a wider range of products without the use of a custom-designed tool.

Pros

– It gives clean and precise cuts due to the optimized power of the beams.

– It has lower maintenance costs and shorter lead times.

– It is ideal for a broader range of materials, including ferrous and non-ferrous metals, wood, plastics, some textiles, and composites.

– The process can handle complex tasks without distorting the cut region.

Cons

– It can emit dangerous fumes.

– It may produce burrs and messy cuts if the materials are too thick.

Applications

Some of the laser cutting applications include:

– Ceramic manufacturing

– Silicon processing

– Medical devices production

– Jewelry industry

– Mold, die, and other tools industries

– Aerospace and automotive industries

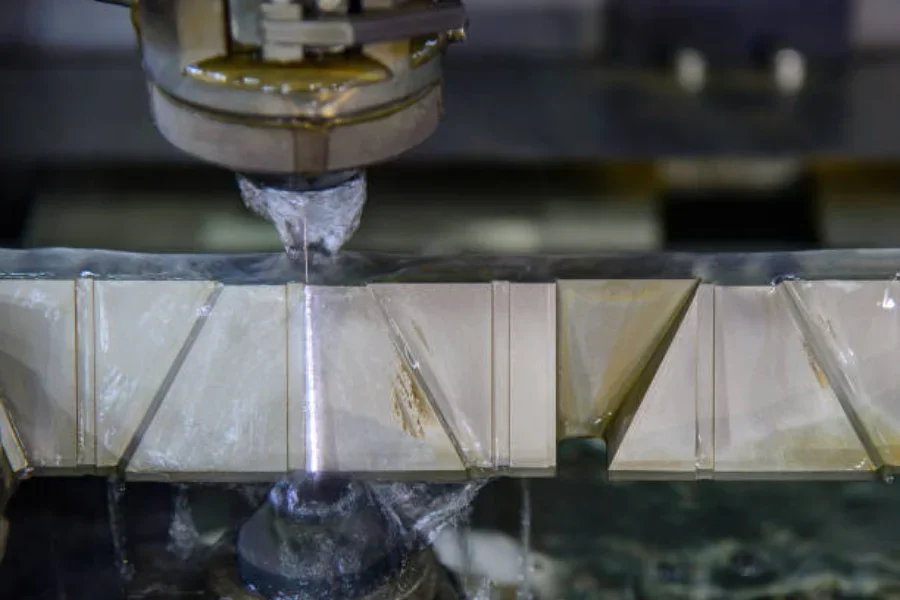

What is wire EDM?

Electrical discharge machining (or wire EDM cutting) is an electrochemical method of cutting materials. The process uses specially designed tools that emit sparks to remove materials with the help of frequent, fast, and controlled electrical charges. Wire EDM is only used on materials that are electrically conductive like metals.

Pros

– It has no negative impact on hard, fragile, and thin materials that are susceptible to bending, stress, and warping.

– It has a higher tolerance than laser cutting so it is more precise and gives more accurate dimensions.

– It can cut materials with a wider range of hardness

Cons

– It is only limited to materials that can conduct electricity.

– The process has a slower cutting speed compared to laser cutting.

– It is not ideal for cutting tubing.

Applications

Wire EDM is often used for:

– Large items like stainless steel metals that require high-quality precision and polishing

– Fragile and small parts that can be damaged by other traditional processes

– Parts that need narrow slots and complicated forms

– Large materials with tight tolerances

– Any other materials that are uncommon, delicate, expensive, and hard

The differences between laser cutting and wire EDM

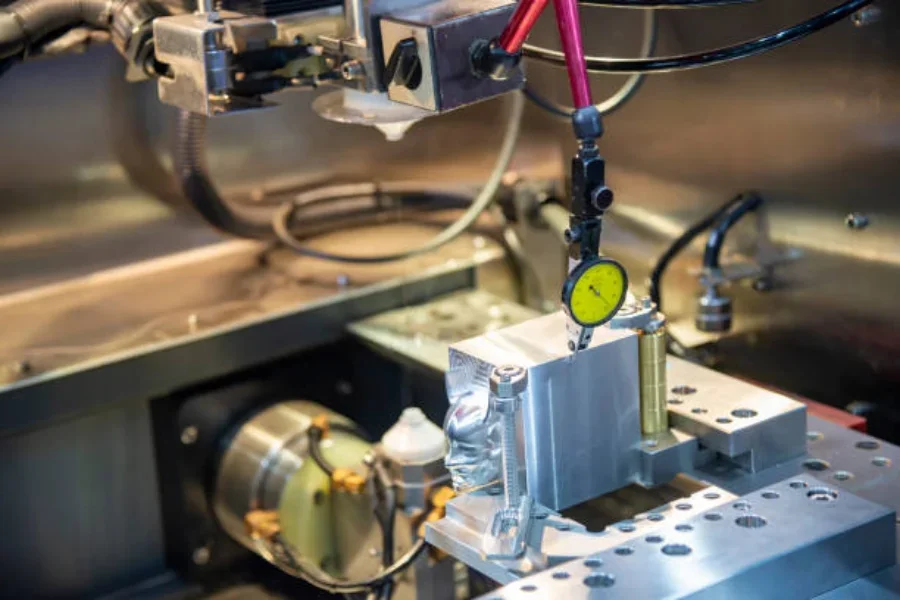

1. Tolerances

Averagely, in every thin material, laser cutting achieves tolerances of about 0.002 inches. The tolerance is based on the thinness of the material. As a result, as the material thickness increases, the tolerance decreases. Meanwhile, wire EDM cutters attain tight tolerances of about 0.0001 inches with more precision and accuracy. This results in slower cutting compared to laser cutting. Buyers should select wire EDM for products that have extreme tolerances or need immaculate precision.

2. Speed

When it comes to speed, laser cutting provides fast cutting speeds on materials with thicknesses of about 0.25 inches or 6.35 millimeters. This means thicker materials require higher-power lasers and gas tubes to achieve similar speeds. On the other hand, wire EDM is often slower than laser cutters but offers increased precision. It can cut materials from 0.001to 16 inches thick.

3. Materials

Wire EDM cuts using electricity hence the materials being cut must conduct electricity. This means the process is limited to metals or alloys. On the other hand, laser cutters are suited for light, mild, and non-reflective materials. This is because the process begins with a contact point which must first pierce through the entire workpiece.

4. Residue

Both cutting methods produce residue during and after the cutting process. However, in the wire EDM process, the residue can be washed away in dielectric water to eliminate its effect on tolerances. Laser cutting, on the other hand, creates slag that can bake onto the surface of the material.

5. Cutting

Laser cutting utilizes a thermal beam to cut materials through burning, melting, and vaporization. In contrast, wire EDM uses a super thin energized wire to cut through workpieces.

6. Limitations

Although laser cutting is limited to thinner materials, it cuts a wider range of materials that are light, mild, and non-reflective like steel, aluminum, copper, stainless steel, and brass. On the other hand, wire EDM is suited for cutting electrically conductive materials, that is, metals and alloys.

7. Cost

Laser cutting is associated with speed and precision so it is more efficient and cost-effective compared to wire EDM. On thin materials especially, laser cutting has reduced lead times and cuts down on material scrap to produce high-quality products that are less costly. However, the presence of slag and burrs makes the materials messier as the thickness increases. In contrast, wire EDM is generally slower as it only cuts harder and thicker metals and alloys. It uses more time and slows down production, hence extending lead times. Also, wire EDM requires extra tooling, which makes the process more expensive.

Conclusion

Wire EDM and laser cutting have many similarities when it comes to cutting and shaping materials. However, from the above information, buyers should understand that wire EDM is more suited to cutting thicker, electrically conductive material parts that tend to be difficult to manipulate using other cutting methods. On the other hand, laser cutting machines cut thin workpieces like metal sheets at a faster rate. Notably, both machines have benefits and downsides. This means that buyers should select the appropriate cutting technology among the two depending on their production needs. To find quality laser cutting and wire EDM equipment, visit Alibaba.com.