Floor grinding machines are walking machines that use a single or multiple rotary heads to remove a small layer from a floor surface. There are several types on the market, with differing applications, from removing stains on soft surfaces such as wooden parquet to smoothing concrete, granite, or marble. This article looks at the range available, explores the main differences between them, and offers some selection guidance for those in the market.

Table of Contents

The projected global market for floor grinding machines

An introduction to floor grinding machines

Comparison of different types of grinding head

What to consider when selecting a floor grinder

A sample of floor grinding machines available

Final thoughts

The projected global market for floor grinding machines

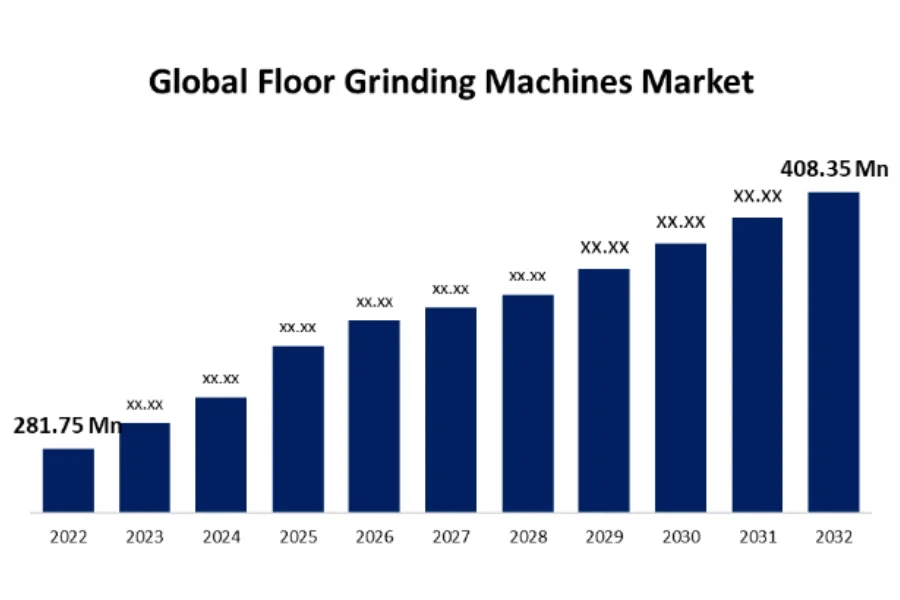

In 2022, the floor grinder market was valued at US $281 million, with that market expected to grow at a compound annual growth rate (CAGR) of around 3.78% to a market value of around US $408 million by 2032.

Asia-Pacific is expected to dominate market share over the projected period, at almost 47%, due to the increase in residential and commercial construction across major countries, such as China and India.

An introduction to floor grinding machines

Floor grinding machines are used to grind down uneven, newly laid concrete and granite and to grind off stains and scratches, adhesives, and paint from heavily used floors. Floor grinders use heavy-duty rotating disks that grind off the top layer of the floor and smooth the surface, grinding down to around ⅛” (3 mm).

Floor grinders are typically used to prepare the surface before final polishing, finishing, or coating with a protective paint or varnish. Floor finishing can then be completed by floor scrubbers and polishing machines. There is some overlap in functionality, as a grinder can create a fairly smooth polished surface on concrete or granite, but polishers are not designed to remove surfaces and use polishing disks rather than grinding ones.

Floor grinders are used on hard floors, such as concrete, granite, or marble, or on softer materials, such as epoxy or wooden parquet flooring. The grinding process creates a lot of dust, so modern grinding machines have two features to manage this: wet grinding water injection and dry grinding vacuuming.

With wet grinding, the grinder uses a water injection feature that is used to absorb and reduce dust. This also helps to give a smooth movement across the floor and reduces excessive friction that might cause burning on the floor surface.

With dry grinding, the grinder uses a vacuuming feature to reduce the dust. The grinder is designed with a dust cover, or shroud, that extends around the grinder to reduce dust spread. However, their effectiveness will not be 100%, and there can still be excessive dust spreading through the grinding process.

Modern grinders are electrically powered and feature speed controls, water injection, or dust vacuuming controls. Higher-end models come with digital displays and remote control.

Comparison of different types of grinding head

There are two types of rotary grinding: planetary and rotary. Each has a different grinding disk or head design and moves in a different way, with each having their own specialties and strengths.

Rotary grinders

Rotary grinders use a single large rotating disk with a single central gear system, such as the one above from Changge Tongya Machinery, which shows 16 separate grinding heads fixed to the disk. These grinders are heavy and very effective at heavy-duty grinding. They come in various sizes and powers, with differing numbers of grinding heads, so different versions are suited to specific tasks and materials. These machines have the following advantages and disadvantages:

Advantages:

- These are “muscle machines” suited for big jobs that don’t require more subtle or sophisticated smoothing

- Good for concrete floors due to their quick grinding and high revolution

- Suitable for large areas of grinding and large-scale grinding roles

- Their heavy weight makes them very efficient for heavy-duty grinding

- Good choice for preparing large concrete or granite areas for later finishing

- Simple rotary mechanism means fewer moving parts and fewer maintenance issues

Disadvantages:

- Require training to use due to their weight and grinding mechanism

- Heavy machines that are not easily moved around by the operator

- Use is normally from side to side in an arc

- Single disk grinding can lead to uneven or “spot” grinding, especially at high speeds or without suitable training

- Specialized application to floor types

Planetary grinders

Planetary grinders, such as the above model from Xingyi Stone Caring Tools, use multiple heads that rotate counter to the main disk. They can come with two, three, four, or multiple rotating disks. The combination of small rotations within a large rotation provides flexibility and even contact with the floor. Their common advantages and disadvantages are:

Advantages:

- Lightweight, easy to use, and easy to move around

- Multiple choices of size and application

- Good for small to medium jobs

- Smooth and even contact with the floor and more even results

- Can grind in straight lines due to the multiple heads

- Usually more affordable than rotary machines

Disadvantages:

- Less suitable for large, heavy-duty jobs and may not have sufficient power or grinding capability.

- More moving parts, additional belts, and gears that can lead to more maintenance problems.

What to consider when selecting a floor grinder

For anyone looking to choose a floor grinding machine, there are a few considerations other than just budget.

The first question to consider is the nature and size of the job and the type of floor to be treated. What type of floor is to be ground, and how large a surface area is to be treated? How fine a result is wanted, and is this intended to be the final finishing before a polish?

This helps to address the biggest decision, which will be the type of grinding head and the size of the machine. For example, for a large-scale concrete or hard-surfaced floor, an industrial-sized grinder with a rotary head may be the best choice, as they are designed for large, tough jobs. For smaller and finer grinding, a more modest-sized planetary grinder may be a better choice.

The next question to ask would be whether a wet or dry grind is preferred or necessary for the environment. Grinding can create a lot of dust, so a floor grinder that offers a dust vacuum or a water injection feature may be preferred. Make sure that the dust cover contains much of the dust or water from spreading around the room.

Additional questions, related to the size of the job as well as the budget, would be: what extra facilities or functionality are needed? For example, is a remote control desired, or will the operator be required to push the grinder constantly?

Are multi-speed and multi-grinding heads wanted, and how easy are they to change? Is a multifunctional grinder preferred that can handle heavy grinding but also additional polishing/ and finishing?

A sample of floor grinding machines available

This model of rotary floor grinder from Changge Tongya Machinery has options for different types of grinding disks, with the above image showing a 32-head disk. It has a working width of 10” (250 mm) and comes with a fitting above the grinder to attach a water hose for wet grinding. It is available for between US $280 and US $300.

This model from Changsha Honway Machinery has a 15.7” (400 mm) working width and an adjustable (floating) dust cover. It has a high motor rate of 1,440 rpm and is marketed as suitable for removing marks from epoxy and for grinding concrete. It is available for between US$950 and US $1,095, depending on the number of units ordered.

This rotary head floor grinder from Hangzhou Bycon Industry has a working width of 10” (250 mm) and comes with a vacuum suction and floating dust cover for dry grinding. It can be supplied for between US $649.20 and US $720.

This heavy-duty rotary floor grinder is particularly suited for heavy concrete grinding and has a variable speed range of 300 rpm to 2,800 rpm. It is available from Beijing Bcd Technology for between US $800 and US $1,500, depending on the actual model chosen and the number of units.

This rotary floor grinder from Henan Zonelion Heavy Industry has a 13” (330 mm) working width and a dust vacuum suction feature with a floating dust cover. The price ranges from US $350 to US $389.

This model from Changge Fuhang Construction Machinery Company has a planetary grinder with a 13.7” (350 mm) working width that is suitable for grinding concrete, marble, and epoxy surfaces. It has a dust vacuum hose, a fan, and an adjustable dust cover. It is available for between US $370 and US $410, depending on the number of units ordered.

This planetary floor grinder from Fujian Xingyi Intelligent Equipment Company has a working width of 19” (490 mm) and is suitable for concrete and other hard floor materials. It has a water injection function with an adjustable dust cover. It is available for US $500 per unit.

The above model from Guangzhou Geanes Industry & Trade Co. is a planetary grinder that can also be used for polishing. It is designed for both grinding and cleaning of hotel floors and can be fitted for 17” (437 mm) or 18” (457 mm). It retails for between US $360 and US $450, depending on the number of units.

This larger-size planetary grinder from Shanghai Jiansong Industry and Trade Company has a 570 mm working width and is available for between US $6,952.00 and US $7,002.00. It has both wet and dry grinding features, three operating speeds, and adjustable weight/grinding pressure.

This planetary floor grinder can handle both wet and dry grinding, and it comes with a water tank and a dust vacuum hose. It has a working width of 21” (550 mm) and is available from Fuzhou Bontai Diamond Tools Company for between US $4,461.53 and US $4,461.53.

There are also much larger and more advanced machines available, such as this large 31.4” (800 mm) working width planetary floor grinder from Liaocheng JADE Outdoor Power Equipment, which costs between US $6,680 and US $6,780.

Their range of large industrial grinders has flexible and ergonomic controls, and some of their bigger grinders have fitted seats and remote control handsets with displays.

Final thoughts

When choosing a floor grinding machine, consider the type of grinding head, and the size of the machine. Is wet or dry grinding preferred? Water injection keeps dust down and smooths the grinding. Dry grinding creates a lot of dust, so a dust vacuum feature would be preferred. Some machines come with a remote control, and others offer multi-speed grinding.

If switchable grinding heads are desired, are they easy to change? If a multifunctional grinder is wanted, look for a machine that can manage heavy grinding as well as additional polishing and finishing.

The shrewd potential buyer will make sure that the chosen floor grinder will meet the end customer’s needs in all respects. For more information on the wide selection of floor grinding machines available on the market, check out the online showroom at Alibaba.com.