When people say they need a die-cutter, they often imagine a single, catch-all device that squashes paper or plastic into neat shapes. In reality, the world of die cutting spans various different machines, including flat-bed steel-rule presses, high-speed rotary converters, servo-driven digital knives, CO₂ or fiber-laser cutters, and hybrids that switch between steel and photons in the same frame.

Each type excels when it comes to using a different substrate, tolerance, and production volume cocktail, meaning buying on headline speed or tonnage alone is the shortest route to post-installation regret.

Read on to discover everything you need to consider when choosing a die-cutting machine.

Table of Contents

Choosing your platform

1. Flat-bed steel-rule presses

2. Rotary die-cutters

3. Digital knife, laser, and hybrid cutters

Other important things to consider when choosing a die cutter

1. Cutting force, platen dynamics, and die life

2. Registration accuracy

3. Speed and throughput

4. Tooling change-over

5. Material handling, feeding, and delivery

6. Control electronics, servo Architecture, and IoT connectivity

7. Safety, compliance, and operator comfort

Wrapping up

Choosing your platform

1. Flat-bed steel-rule presses

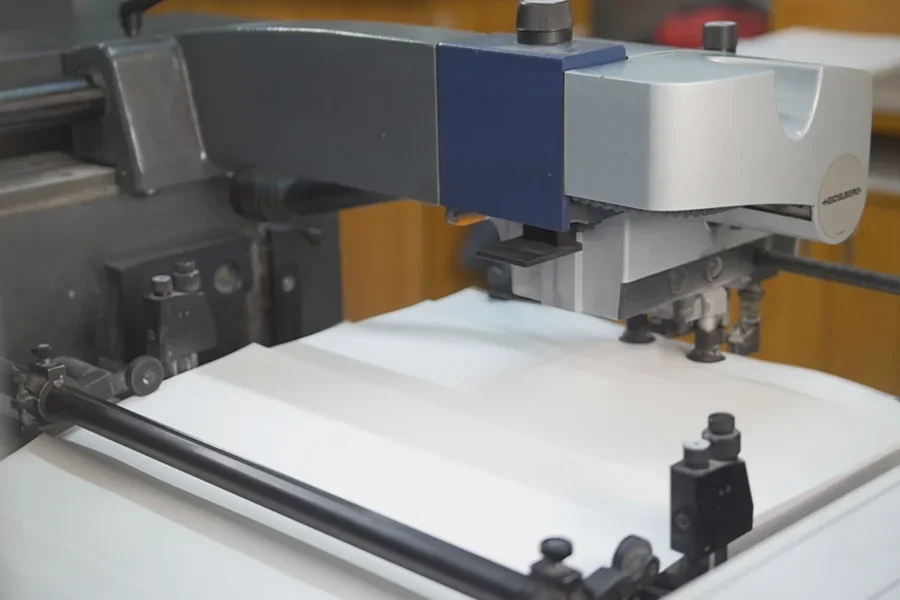

A flat-bed die cutter resembles an industrial sandwich press, with a press that lowers onto a bed holding a steel-rule die. Because they work vertically, flat beds are ideal when working with thick paperboard, corrugated, foam, and gasket stock.

Modern servo presses even regulate pressure within a few microns, dramatically reducing the instances of tear-out that are often encountered on older crank presses. Machines like the latest Heidelberg Polar series wrap that muscle into an automatic register system that talks directly to the print tower, working sheets into stripped stacks in one continuous movement.

2. Rotary die-cutters

Instead of stamping, rotary machines feed the web through a pair of cylinders – one carrying the die and the other acting as an anvil. Because the web never stops, throughput can exceed 200m min-1 on pressure-sensitive labels and flexible packaging.

In addition, servo cylinders decouple the cutting roll from the drive line, allowing you to swap dies without resetting an entire gear train. This feature reduces changeover time from 40 minutes to under 10 on some models from 2024 onward.

3. Digital knife, laser, and hybrid cutters

Many graphic-arts plants that traditionally exist on short-run SKUs are turning to digital flatbeds whose heads carry tangential knives, creasers, and even plasma knives. These lack physical dies, so every shape is just a vector file away, and camera systems automatically register each sheet against printed fiducials.

Where knife drag would distort vinyl or leave a burr on PET, laser modules jump in. Hybrid frames such as the Dorey intelligent laser/rotary unit can toggle between modes in software, turning what used to require three machines and a forklift into one cell.

Matching the platform to the product is the first thing you must consider. For example, a rotary machine will outrun any flatbed on 50 µm PET liners, yet a servo flat-bed can punch a hammock-strap hole through 5-mm EVA where the rotary would stall or delaminate the web.

Other important things to consider when choosing a die cutter

1. Cutting force, platen dynamics, and die life

Ask 10 vendors about tonnage, and nine will say the peak number is the most important factor. What matters more is how that force is delivered. For example, a servo-hydraulic flatbed reaches set pressure in milliseconds and then holds it rock-steady for the microsecond needed to cleanse fibers thoroughly.

Meanwhile, a mechanical toggle press delivers a bell-shaped force curve that adds pressure to the die board. Rotary systems live by a different metric: lineal pressure in N mm¹ of die circumference. Pair a hardened tool steel die with a soft urethane anvil, and you can “kiss-cut” labels so that only the face stock is severed and the liner remains intact.

But if the anvil hardness drifts off spec, the kiss becomes a through-cut and a can waste roll. Closing that loop is why premium rotaries ship with laser-drilled vacuum anvils that measure compression via onboard load cells on every 10th revolution.

2. Registration accuracy

Cutting around artwork boundaries is no longer enough. Brand owners now demand that foil stamps on their designs land within ±0.15 mm of the die-cut window, as the transparent film behind must align with the barcode grade.

Achieving that precision starts with the machine detecting where the print is. Onboard cameras (often 4k CMOS running at 1,000 fps) can scan registration marks on the fly. Simultaneously, a servo algorithm nudges the cylinder phasing or the flat-bed sheet grippers in less than 20 milliseconds, so the die always meets the ink exactly.

The wrinkle arrives when the substrate stretches or shrinks as humidity waves through the plant. Digital twin models running in the controller (a feature borrowed from CNC lathes) predict how much web tension will elongate PET at 40°C and auto-deselect dies that would otherwise drift off registration.

That kind of cyber-physical foresight used to be R&D theater. In 2025, however, it ships with mid-tier automatic presses thanks to cheaper edge computing and open-source MQTT pro.

3. Speed and throughput

A spec sheet might be able to handle 9,000 sheets an hour, but add stripping, blanking, stack turning, and pallet change-over, and the real-world carton count could be half that. Look instead for cycle-time details that include auxiliary modules. For instance, a press that integrates gripper edge trim removal straight into the rule frame can eject blanks immediately; otherwise, you need a separate stripper, which slows downstream folder-gluers.

In roll-fed work, the main action usually involves the waste-matrix rewind, which can split mid-run and force an operator to crawl inside the tunnel and tape it back together. The result is five minutes lost at 180 m min¹ and 900 metres of wasted laminate.

On the other hand, modern machines snake the matrix under a vacuum conveyor, eliminating rewind drag entirely and lifting effective productivity by double-digit percentages without turning the line one RPM faster.

4. Tooling changeover

If your plant juggles dozens of SKUs daily, every minute the press is idle will eat that margin. That’s why fast-make-ready systems clamp steel-rule dies with pneumatic pins from below. With this system, the operator can slide a jig onto rails, press a button, and the servo posts will lock the board flush.

Thankfully, rotary lines have magnetic dies for easy changing, while laser die-cutters sidestep the physical changeover altogether. Once you upload a new PDF, the beam will draw a fresh geometry. The trade-off is energy cost and edge browning on white SBS, but the math increasingly favors photons for longer runs under a couple of thousand copies.

5. Material handling, feeding, and delivery

High mechanical accuracy is useless if the sheet arrives skewed. Consider looking for feed tables equipped with ultrasonic edge sensors that measure sheet width on the fly and bias the side-guide servo to compensate for ±0.3 mm mis-cut stacks.

If you want vacuum belts, choose options with differential holes to keep laminated substrates flat without over-stretching the face stock. On rotary web lines, servo-tension zones split the unwind, infeed, cutter nip, and rewinder into independent parts, synchronised by Ethernet-based motion buses that correct tension every 4 ms.

Pro tip: Listen for the web dance when you test a machine. Big swings in the dancer-arm angle betray tension overshoot, which can mean die-cut wander down the line.

Delivery automation should also be ergonomic and scratch-preventive. Consider drop-down air tables that “float” freshly cut blanks onto jogging rails, so the foil or UV varnish is likely to be scraped by operators.

On the other hand, robotic stackers now read QR codes that the press prints on the grip edge. They automatically align piles to the downstream folder-gluer queue, meaning your best pressman no longer spends a shift realigning pallets with a pallet jack.

6. Control electronics, servo architecture, and IoT connectivity

Under the hood of any 2025-vintage die cutter sits a motion controller that coordinates 40 servo axes, a gigabit camera channel, and half a dozen safety zones. However, the difference between an open architecture that logs every servo move and one that hides its PLC ladder is important in the event of drifting.

Machines advertising OPC UA or MQTT endpoints push live data, like motor torque, cut-torque spikes, and oil temperature, straight into your plant’s MES. Vendors leaning into Industry 4.0 even bundle a year of cloud analytics that turns that stream into predictive maintenance alerts: a rising RMS current on the cut cylinder often means a chipped rule or a dry bearing weeks before scrap appears.

But don’t forget cyber-security in motion networks. Always look for controllers that support certificate-based TLS and segmented VLANs. They will spare you the choice between air-gapping the press and risking downtime during an attack.

7. Safety, compliance, and operator comfort

A 200-tonne platen descending on an operator’s hand is a nightmare nobody wants, which is why the latest presses surround the feed zone with light-curtain arrays instead of mechanical gates. If something enters the feed, the servo valves dump pressure and stop within 50 mm of travel, less than the thickness of a sugarcane board.

Laser cutters can pose a Class 4 optical hazard, and normally come wrapped in a fully interlocked enclosure that reduces them to Class 1 on the shop floor. Still, check that each door has redundant reed switches and that the controller logs bypass events for audit.

Ergonomics should not be a luxury, either. A low-decibel vacuum pump under the feed table and LED floodlighting above the die bed halves reduce operator fatigue on night shifts.

Wrapping up

Choosing a die-cutting machine in 2025 involves weighing up mechanical engineering, data science, and old-fashioned operator convenience. Platen tonnage, rotary surface speed, and laser wattage still matter, but only in the context of servo control finesse, camera-driven registration, AI-augmented maintenance, and the human workflow that stitches those pieces together.

If you anchor your shopping on the features explored here (and challenge vendors to demonstrate them on your actual substrates), you should be able to find a cutter that turns your design files into profit.