Animal feed mixers are an essential piece of equipment for anyone in the livestock business. Whether farming chickens, pigs, sheep, or cattle, animals require a nutritious and balanced diet to promote healthy growth.

Leaving animals to forage for their own food may be the natural way to feed them, but weather changes can impact forage availability and quality. Therefore, supplementing their diet with prepared fodder, mixing feed with nutrient-rich meal and additives, is the desired solution.

When mixing feed, it is important to combine all ingredients evenly and thoroughly to ensure each animal receives a consistent feed. Animal feed mixers come in a few different types. This article explains the choices and provides examples of the other machines available.

Table of Contents

The global market for animal feed mixers

What are animal feed mixers?

Types of animal feed

Animal feed mixers

Vertical orbital screw mixers

Horizontal paddle or blade mixers

Final thoughts

The global market for animal feed mixers

Increasing demands for healthy and high-capacity livestock farming create the need for reliable and nutritional feed solutions. Animal feed needs to be mixed consistently, evenly, and efficiently to ensure a homogenized mix, either for direct feed to animals or as part of a commercial feed manufacturing process. This demand has seen the animal feed mixer market grow by a healthy compound annual growth rate (CAGR) of 5.5%, from around USD 1.3 billion in 2023 to a projected USD 2.1 billion by 2032.

What are animal feed mixers?

Types of animal feed

Before talking about animal feed mixers, let’s start with a consideration of what constitutes animal feed. Domestic animals and farming livestock, such as cows, sheep, pigs, and chickens, need to be fed healthy and nutritious food. Animals eat either fodder or forage.

Forage is food that animals find for themselves. Food that they may discover would include grasses, immature crops, crop residue, and plants. Cattle and sheep graze in their fields, pigs root in the dirt, and chickens peck at the ground.

Sometimes, if the fields are a little bare or the grass is harder for the animals to access, perhaps during frosty weather, food is brought into the fields and paddocks for the animals, towed in by tractors and then forked into the field or paddock. Then the animals wander and eat at their leisure. The quality of the forage will vary, and animals may not get all of the nutrients that they need, so mixing ingredients into fodder is popular for livestock farms.

Fodder is feed that is taken to the animals. This can include straw and hay, silage (fermented crops), sprouted legumes and grains, oilseed crop byproducts like soybean cakes, and compressed or pelleted feed.

Fodder may be fortified with additional nutrients for the animals, which is often done in feed mixers. The increasing demand for livestock farming creates a need for reliable, high-nutrient feeding solutions to promote animal health and growth.

Animal feed mixers

Animal feed mixers are used extensively to mix fodder, to integrate additional ingredients, premixes, and nutrients. The critical aspect of a feed mixer is ensuring that all of the feed and additional ingredients are properly mixed and evenly distributed to give a well-balanced ratio throughout the feed. The mix ratio would be determined to ensure that the animals are getting a well-balanced nutritional blend.

Mixed feed is typically used to compress into feed pellets or feed mash. An uneven mix would give an unbalanced feed spread across the mash or pellets, so that nutrients and supplements would be integrated unpredictably. The farmer would not know which animals ate more or less of the feed ingredients, which can lead to malnutrition or excessive nutrients. Either situation can create health issues for the animals..

The two different types of animal feed mixers are vertical and horizontal. Let’s take a closer look at each:

Vertical orbital screw mixers

Orbital screw vertical mixers use one or more vertical screws, or augers, in a large upright container. Feed is loaded from the top and falls to the bottom through gravity. The screws are designed to move the feed upwards to the top of the mixer, which then falls back down to the bottom to be remixed.

This continuous cycle of moving up and dropping down provides great blending results. Their upright design is space-saving, making them particularly helpful for more compact working areas with limited floor space. They are flexible in the range of feed that can be added, including fodder and forage, grains, and nutritional supplements.

Their convenience makes them most suitable for dairy and beef farms, and they are a popular choice for small to medium farms and feed mills.

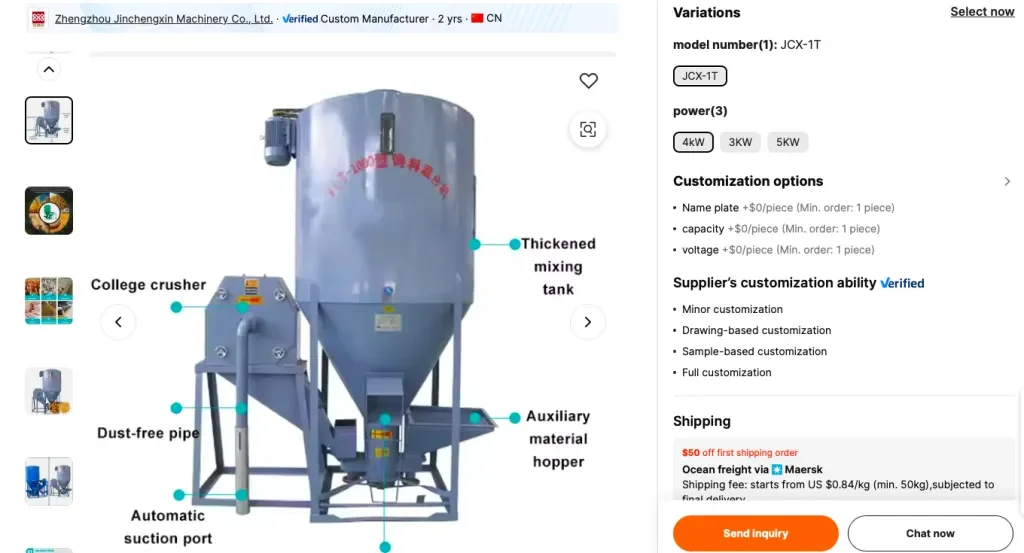

This diagram of an orbital screw vertical animal feed mixer comes conveniently labelled with its key components. It offers a processing speed of 1 ton per hour and is suitable for chicken, pig, and cattle feed mixes. Prices range from USD 499 to USD 1,399 depending on the number of units ordered.

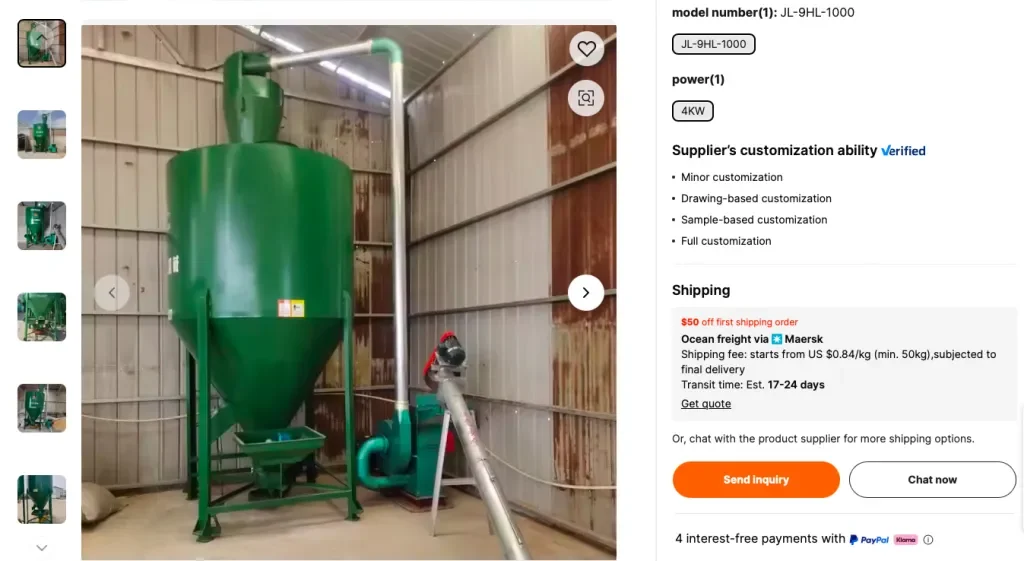

This model is another example of an orbital screw vertical animal feed mixer, which is advertised as suitable for poultry farms. It has a capacity of up to 1 ton per hour and is available for USD 670.

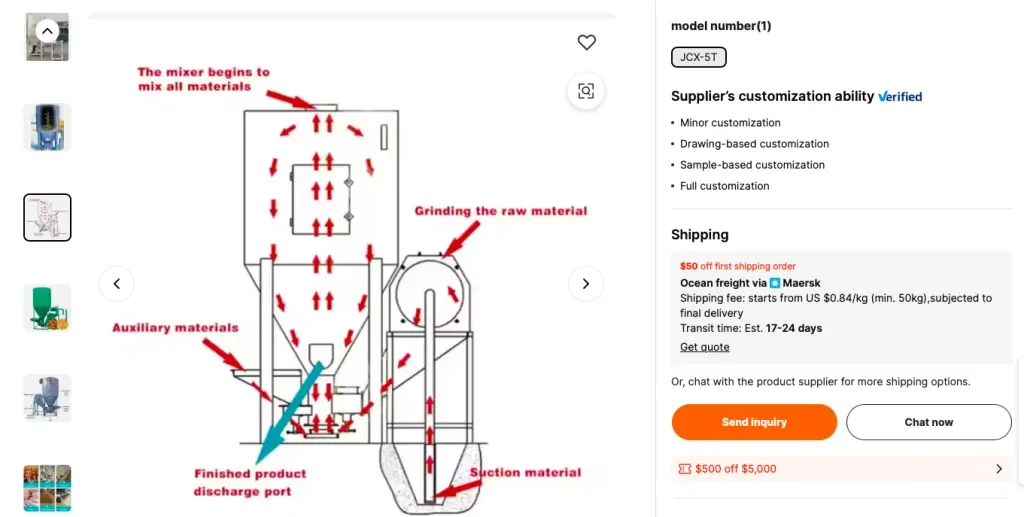

Although most orbital screw vertical mixers for animal feed look very similar, their internal mechanisms may differ slightly. This model helpfully annotates all of the key processes, showing the upwards movement of the screw and the gravity fall of the feed, as well as showing the finished product outlet port. It is advertised as suitable for chicken and pig feed, but specifications indicate suitability for other livestock too. Prices for this model range from USD 900 to USD 1,700, subject to the number of units purchased.

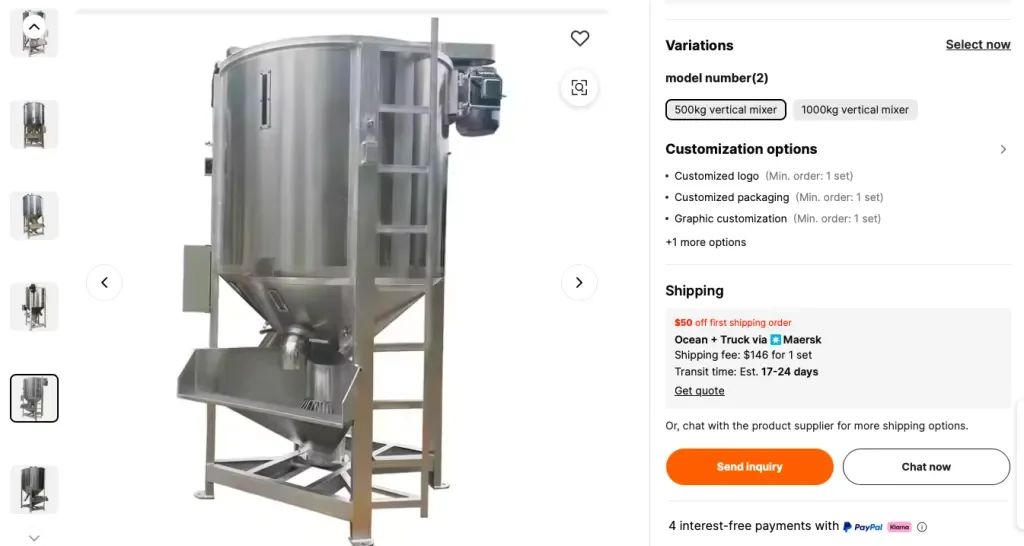

This stainless steel vertical animal feed mixer also has a capacity of up to 1 ton per hour, and is suitable for most animal feed types. It sells for between USD 1,480 and USD 1,780, subject to units ordered.

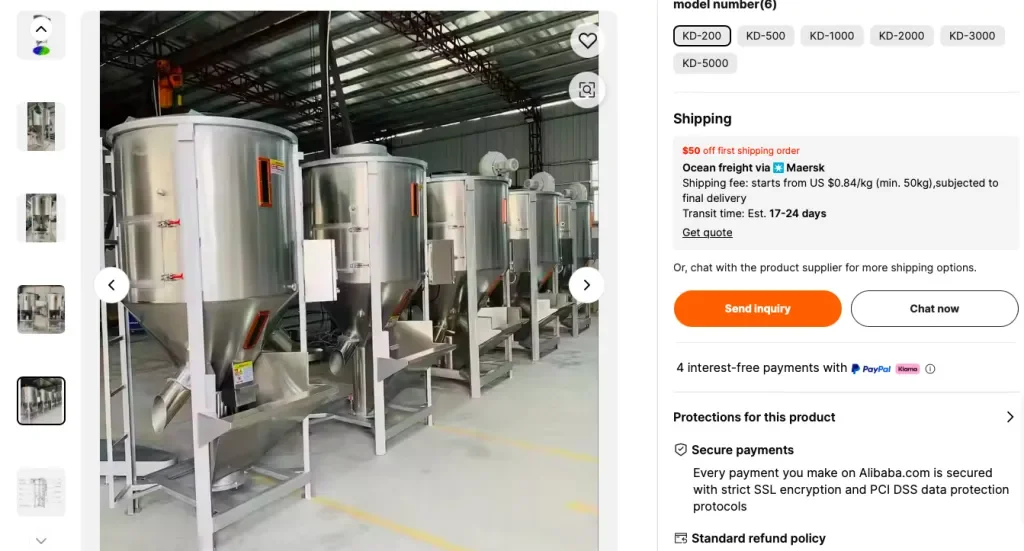

This orbital screw vertical animal feed mixer features an array of machines lined up for industrial processing. These machines are priced at USD 500 to USD 590, depending on order quantity. As with other similar models, this offers a throughput of up to 1 ton per hour and advertises as suitable for a wide range of feed mixing, as well as feed pellet production.

Horizontal paddle or blade mixers

Horizontal mixers use rotating paddles (paddle mixers) or blades (ribbon blenders), which are attached to a horizontal motor, within a horizontal mixing chamber. These chambers are typically barrel or trough-shaped. Ingredients are loaded from the side, and the feed is then moved from one side to the other by the paddles or blades.

They provide for faster mixing times and can handle large loads, giving very uniform mixing results. This makes them very suitable for high-capacity mixing requirements, such as for large livestock or poultry farms, commercial feed mixers, and feed manufacturers.

Examples of horizontal mixers available on Alibaba.com include:

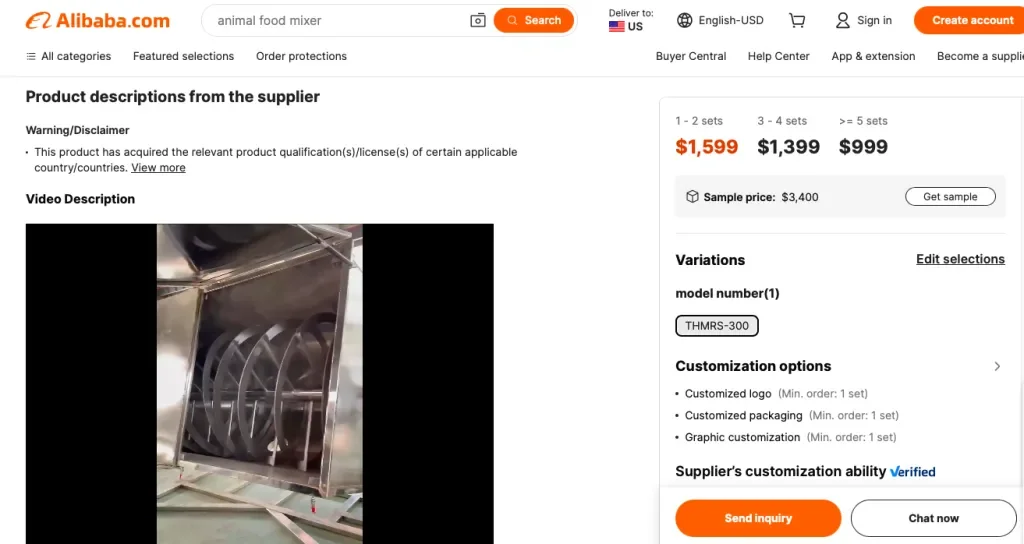

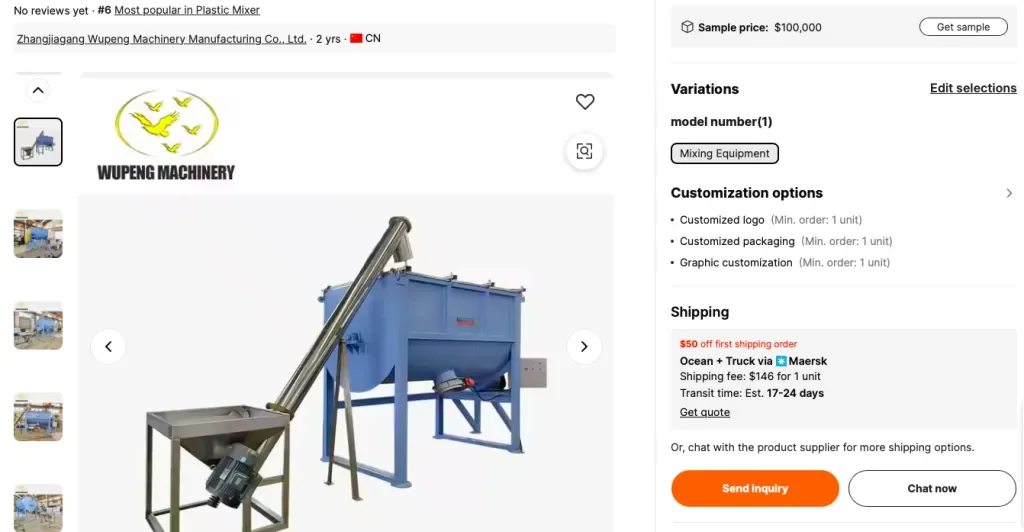

This industrial horizontal animal feed mixer features a double helix ribbon blender and is available in various capacities: 100kg, 300kg, 500kg, 900kg, and 1 ton. It is advertised as suitable for vitamin, protein, and mineral feed. Prices range from USD 999 to USD 1,599 depending on size and units ordered.

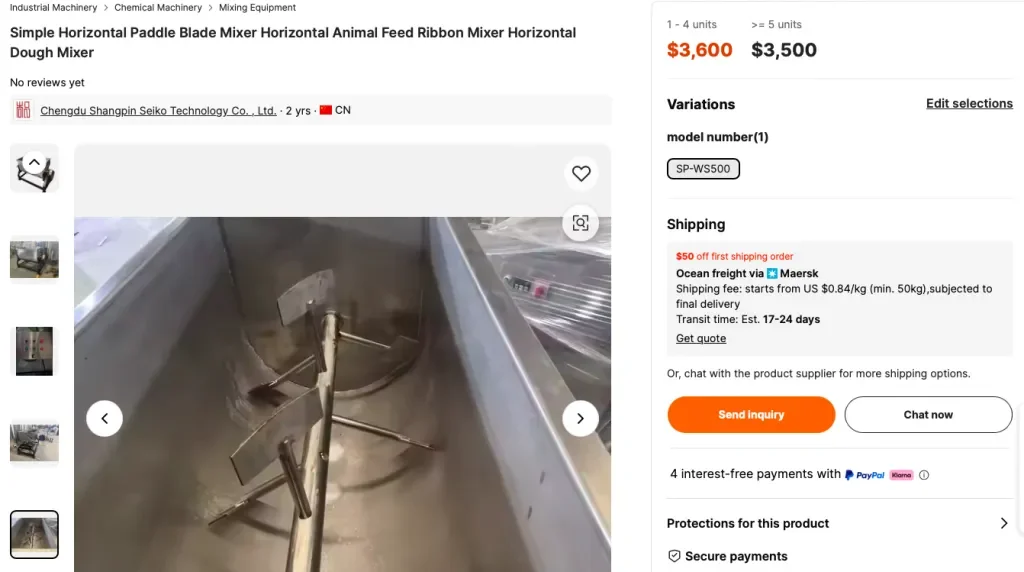

This model is a horizontal paddle mixer for animal feed. Its specified barrel volume is 500kg, which makes it a smaller capacity mixer than others shown here. It is priced at between USD 3,500 and USD 3,600, depending on the number of units purchased.

This large-sized industrial horizontal animal feed mixer has double ribbon mixing, and is priced at USD 530 per unit. It doesn’t specify its throughput per hour, but has a barrel or trough capacity of 300kg, and the marketing material states that it can feed between 200 and 1,500 dairy cows per day (depending on hopper size).

The above model large industrial animal feed mixer has a horizontal orientation and a ribbon mixer and comes in different sizes/capacities, from around 150L to 1200L. For each capacity, the proposed mixing time is shown as 8-12 minutes per batch (full barrel). Pricing is from USD 990 to USD 1,380, subject to order volumes.

This model of horizontal animal feed mixer has double shaft paddles for fast mixing. It comes with a capacity of 200kg to 500kg. Pricing is between USD 2,900 and USD 3,500, depending on the number of units ordered.

Final thoughts

Choosing the right animal feed mixer is vital for ensuring livestock nutrition and farm efficiency. Mixers fall into two types: vertical and horizontal.

Vertical mixers feature an upright orbital screw or auger that draws feed up to the top of the mixer before allowing it to fall back down again. Horizontal mixers have a large barrel or trough, using single or double horizontal screws that are fitted with paddles of ribbon blades. These turn the feed within the barrel to mix.

Vertical mixers use a smaller floor footprint, making them more efficient for small spaces and small farms. Horizontal mixers take up a much larger area and are typically more suited to large farms and industrial feed processing. All mixer types offer flexibility in the types of feed and additives that can be mixed.

In general, all mixers have their strengths in mixing, but are all designed to mix thoroughly to achieve an even blend of feed components. Horizontal mixers are said to be better for larger volume processing, but the examples given in this article show that vertical orbital screw mixers can also process large volumes quickly.

The wise buyer will explore the choices available against the volumes, space, and type of livestock feed to be used. For more information on the vast options of animal feed mixers available, check out the Alibaba.com showroom.