Choosing the right window- and door-making machines can be daunting for anyone in the woodworking or construction industry. With the abundance of options available, knowing what suits different manufacturers’ needs and budgets can be challenging.

This article will therefore look at selecting the right window- and door-making machine. It will help manufacturers make the right decision so that they can meet specific consumer needs.

Table of Contents

Global market overview of window- and door-making machines

Selection tips for window- and door-making machines

Types of window- and door-making machines

Conclusion

Global market overview of window- and door-making machines

At the beginning of 2020, the window and door industry was estimated to be worth US$ 220,945.25 million. The market is on a streak to grow and reach US$ 356,483.6 million by 2030, representing a CAGR of 4.9% from 2021 to 2030.

Among the factors influencing the growth of the global market is the demand for window and door products. The need for sustainable windows and doors in various countries globally has also strengthened the market. Therefore, door and window manufacturers can enjoy numerous benefits by venturing into reliable machines that construct stable products.

Selection tips for window- and door-making machines

Production volume

The number of windows and doors products it creates is essential when looking for the right equipment. Different machines have different capabilities on how many window or door panels they can produce per hour.

Businesses with small-scale production may consider the equipment that produces a little run of window and door products. Alternatively, large-scale manufacturers can acquire machines with a high production volume to meet their customers’ demands.

Applicable material

The type of material the machine handles is crucial while selecting door and window manufacturing equipment. There are different types of door materials in the market, including wood, metal, and plastic. Businesses should pick the machinery compatible with the type of door or window they manufacture.

Additionally, when buying a specific metal, wood, or plastic door- and window-making machine, it is crucial to consider the compatibility of each specific material type. For instance, when acquiring a machine specifically for metals, businesses should consider whether it is compatible with steel, aluminum, and bronze. The same applies to the other types of materials.

Level of automation

With technology quickly evolving, many industries have adopted machinery automation in their production lines. Machines’ automation levels include manual operation, semi-automation, and complete automation. Each of these levels affects the efficiency and effectiveness of the machinery.

Fully automated machines are programmed to operate for extended periods without stopping. These machines can produce lots of doors and windows while operating optimally. Semi-autonomous machines incorporate the use of humans and robots in their production. Robots can handle the heaviest tasks while human workers work on the less labor-intensive tasks.

While each automation level has more substantial benefits over the other, businesses can acquire different levels depending on the needs of their customers.

Energy source

The type of energy source helps to determine the type of door- and window-making machine businesses should pick. The equipment relies on different kinds of power sources to make the desired shapes and sizes of products. This mostly depends on the size and sturdiness of the material the equipment is working on.

Window- and door-making machines that make huge products may consume more power and thus require a high-consuming energy source. Conversely, machines making small doors and windows may require an energy source with little power.

Precision

The precision of the machine’s output is a crucial aspect that businesses should consider. Aspects like the accuracy of the cuttings and measurements determine the precision of window- and door-making equipment.

Businesses should always invest in equipment that has high precision levels. A good machine should achieve high levels of accuracy while minimizing errors. Ultimately, the customer will benefit from good quality products while the manufacturer maintains a loyal customer base.

Product size

When selecting a window- and door-making machine, it is crucial to consider the size of the products to manufacture. Businesses should consider the machines that manufacture large products appropriately and those that manufacture smaller products appropriately.

With technology advancing, versatile machines can produce large and small products. Such machines can help businesses produce different door and window sizes while targeting many customers.

Types of window- and door-making machines

Double-head cutting saw

It features a metal or woodworking saw with two cutting blades mounted on one machine. The machine makes two cuts simultaneously, making it efficient for accurately cutting larger pieces of materials into smaller pieces. The cutting saws can be fixed or movable to allow various cutting options.

Pros

– They increase efficiency by making two cuts simultaneously.

– They improve the accuracy of the cutting process.

– They are versatile as they can make different angular, straight, and curved cuts.

Cons

– They can be more complex than single-head cutting saws.

– They require more space in a workshop.

Copy router

A copy router is a machine that creates copies of another object. It comprises a rotating spindle with a cutting tool and a moving table with the workpiece.

The machine works by copying the shape of a template attached to the workpiece and using a cutting tool to create an exact duplicate of the template.

Pros

– Manufacturers can use them to make precise cuts and duplicates in various materials, including wood, plastic, and metal.

– They can be equipped with various cutting tools, such as routing bits and shaping knives, for various cutting and shaping capabilities.

– They increase productivity by making multiple copies of materials in a short time.

Cons

– They have high initial and installation costs.

– Rotating swindles and cutting tools can cause serious injury if not handled properly.

Punching machine

Punching machines create holes in wood, plastic, and metal material. The machines make holes for fasteners like screws and rivets or create hole patterns for decorative purposes.

They use a punching tool mounted on a reciprocating ram to strike the material and create holes. Different punching machines exist, whose characteristics vary depending on the size and thickness of the punched material and the speed and precision of the punching process.

Pros

– They are fast at punching holes.

– They are more cost-effective than other hole-making machines like drills.

Cons

– They are suitable for punching specific metals and plastic.

– Limited hole sizes limit their usefulness.

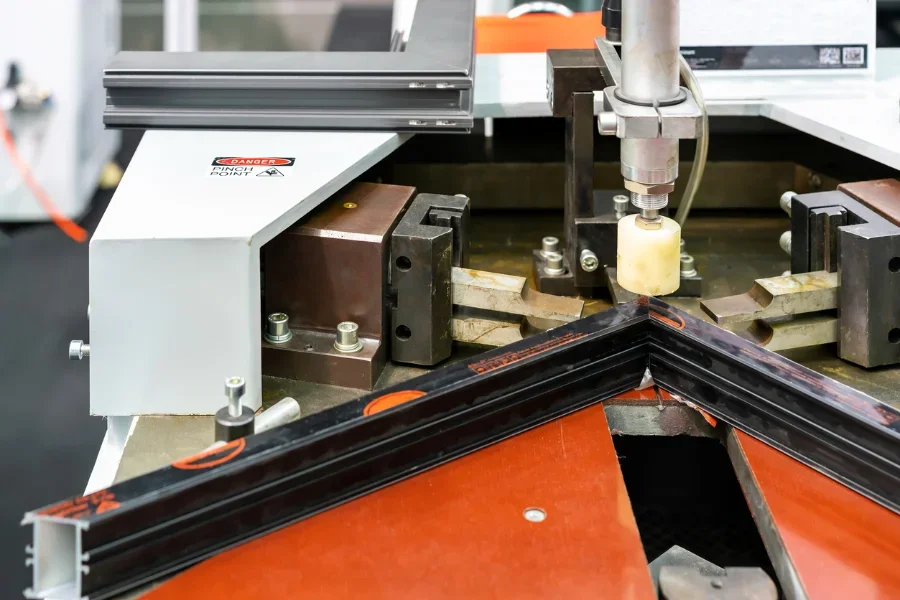

Crimping machine

This machine produces high-quality aluminum alloy doors and windows that suit the ninety-degree angle connection of corner structure doors and windows.

Pros

– They offer consistent quality.

– They are fast and productive.

Cons

– They are limited to metal doors and windows.

Conclusion

Businesses having trouble locating the best machines can consider the above tips to choose reliable equipment. Eventually, they will manufacture high-grade products that satisfy their customers’ needs.

Also read: Guide to Industrial Automation: Types and Methods