During this era of Industry 4.0, the digitization of the third industrial revolution is converging with smart and autonomous systems as well as data and machine learning to bring about an unprecedented age in industrial automation.

In this article, we’ll go over 7 key trends that will be shaping industrial automation. These trends will give buyers insight into where the industry is headed and what consumers will be looking for to optimize their operations.

Table of contents:

Overview of the industrial automation market

Top trends shaping industrial automation

The new age in industrial automation

Overview of the industrial automation market

The size of the global industrial automation market has shown positive prospects over the 2020–2025 forecast period. According to Statista, the market is expected to experience growth in value from US$ 175 billion in 2020 to an estimated US$ 265 billion by 2025.

Growing at a compound annual growth rate (CAGR) of 9%, the market shows strong indications of steady growth. Even in spite of the global health crisis and the resultant supply chain disruptions, there are signs of the market bouncing back.

Fortune Business Insights found that the key drivers behind the growth of the market are the advent of 5G technology combined with the increased adoption of Industry 4.0 among enterprises.

Top trends shaping industrial automation

Now that we’ve got an idea of the overall global industrial automation market, we can delve into the key trends that will influence the direction of the manufacturing industry at large.

1. Industrial Internet of Things

Industry 4.0 will see the convergence of information technology and operations technology (IoT convergence) at a level that will cause unprecedented digital transformation. Industrial IoT will help to connect businesses’ industrial assets in a manner that is transparent, easy, and increases productivity. Businesses will be able to simplify their shop floor software throughout the entire lifecycle and increase the interoperability and flexibility of their operations.

The global manufacturing industry is expected to save a staggering US$ 500 billion every year thanks to IoT-driven automation. IoT is able to help industries identify wasteful inefficiencies, prevent equipment failure, and ensure product quality. In response to RT Insight’s survey, the benefits most cited by industrial IoT adopters include:

- Reduction of operating costs (53%)

- Improving data collection (48%)

- Increasing revenue from existing streams (42%)

Artificial intelligence (AI) will also be a crucial component of Industrial IoT as a number of industrial solutions will use even more advanced analytics as well as edge and cloud computing for their machine data analysis.

Future Market Insights projects that the global market for AI in IoT, which is currently valued at US$ 78 billion, will reach an estimated US$ 142.4 billion by 2032. This growth is understandable considering that machine learning (which is a subset of AI) and IoT are enabling businesses to make operational forecasts that are 20 times faster than traditional technology and offer heightened accuracy.

2. Shift from automated to autonomous

Advances that have taken place within digitization paired with new open-process automation standards have provided manufacturers with the opportunity to shift their operations from “automated” to “autonomous.”

Through AI and machine data, the aforementioned Industrial IoT convergence and digital transformation are enabling manufacturers to create autonomous systems that are capable of making key production or operational decisions while humans merely act as overseers.

Autonomous systems in the U.S. automotive industry are estimated to provide overall yearly savings of up to US$ 1 trillion, which will have a significant impact on the economy. Operating plants will be able to significantly improve the reliability and predictability of their operations. Machines will be able to be trained with key historical data combined with real-time data as well as AI-enabled applications to ultimately increase the efficiency of operations.

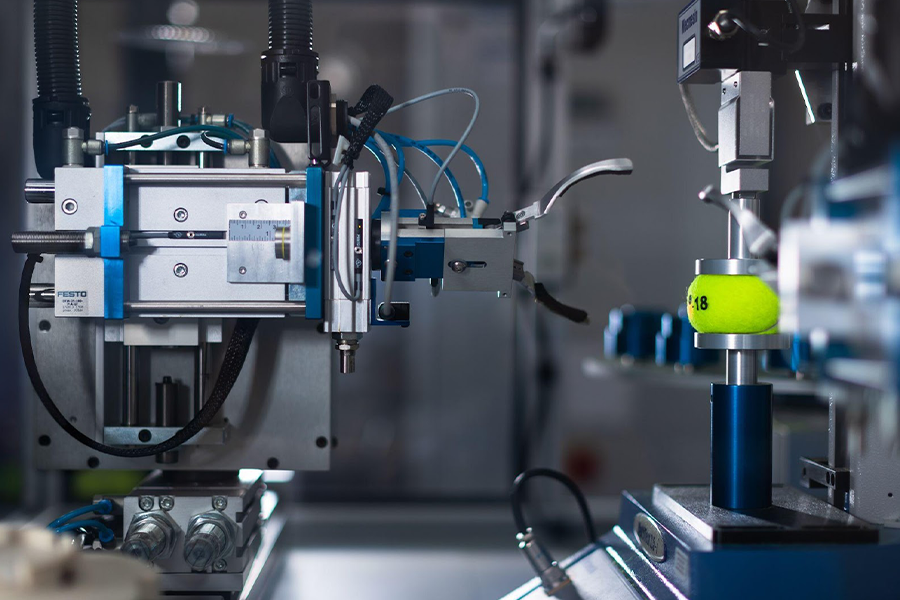

3. Lower cost of robotic arms

Engineering 360 reports that the cost of robots has actually dropped by more than 25% since 2014, and it is expected to drop even further by an additional 22% by 2025. The industrial robotics market was valued at US$ 24.35 billion in 2020 and is projected to reach US$ 52.85 billion in 2026, growing at a CAGR of 14.1% over the 2021–2026 forecast period.

While demand for industrial robots has been increasing, the decreased cost of industrial robotic arms particularly has enabled the use of robotic arms to be even more widespread within the manufacturing industry.

Using machine vision and network technologies, industrial robotic arms help businesses to automate key processes that ultimately contribute to increased worker safety, faster production, and increased productivity. In real figures, the Boston Consulting Group estimates that industrial robotic arms could deliver average global labor-cost savings of about 16% by 2025. In the U.S., these savings could be up to 22%, and in China at least 18%.

Manufacturers are able to buy low-cost robotic arms for a number of applications, from loading arms to precision welders. In the long run, this will help businesses strengthen their competitive advantage as they will be able to keep their costs low and pass on this cost-benefit to buyers.

4. Increased adoption of collaborative robots

Collaborative robots (also known as “cobots”) are seeing increased adoption in industrial automation. As machines that are intended to enable direct human-robot interaction within a shared operating space, cobots are making the transition to automated or autonomous operations easier for businesses all over the world.

Cobots are a relatively new trend in robotics but are becoming more widespread in industrial manufacturing applications. They are being deployed for various tasks across a number of industries including automotive, electronics, general manufacturing, metal fabrication, packaging and co-packing, plastics, and food and agriculture.

In the manufacturing industry, they are being used for picking and placing, in the food industry they are used for slicing and cutting, and in the healthcare industry, they are being used for surgery. When applied in manufacturing, a machine that costs US$ 50,000 can deliver up to US$ 150,000 in savings in packing costs.

One of the reasons for their popularity is that cobots are designed with human operators in mind, and they help guarantee the role of human labor while also assisting in the efficiency, accuracy, and safety of operations.

5. Advances in machine vision

Significant advances in machine vision are enabling automated machines to undertake operations with greater precision and for more complicated tasks.

Machine vision (MV) refers to the technology and methods that are used in industrial automation to provide automatic imaging-based inspection and analysis for applications that include process control, automatic inspections, part tracking, and robotic guidance.

Because of the benefits of high speed, improved efficiency, and accuracy that it enables, the next few years will see machine vision technology being increasingly deployed and integrated with automated systems.

6. Increased reliance on 3D printing

One of the groundbreaking technologies that will impact industrial automation is 3D printing. Automation World notes that 3D printing will be a game-changer within the global automation market as it will significantly decrease the costs of production.

Industrial automation is fast changing and the ability to quickly prototype for R&D that 3D printing enables is allowing businesses to quickly adapt to changing industry demands. 3D printing is now being used in packaging, education, medicine, and construction.

Because of faster prototyping, manufacturers are able to test their concepts more rigorously before they move to the implementation stage and full-scale production. The benefits of this are that new designs are brought to market faster, the costs of R&D are reduced, 40–70% less material is used in the manufacture of products in comparison to traditional methods, and buyers are able to have parts on their automated machines replaced faster.

7. Continued adoption of flexible manufacturing systems

The adoption of flexible manufacturing systems (FMS) has continued among manufacturing businesses across the globe. FMS is a production method that increases adaptability to changes in the quantity or type of product that is being manufactured.

FMSs offer machine flexibility, which refers to how much a system is able to change to create new product types or to change the order of operations of a specific part. FMSs also offer routing flexibility, which refers to a system’s ability to use multiple machines to perform the same operations on a single part.

While these systems may be considered expensive, they serve to increase productivity and reduce the cost of operations. Their ability to adapt to changes also helps businesses prevent defective products and wasted time and resources.

BrainKart reports that FMSs deliver increased machine utilization compared to machines in conventional batch productions, enabling businesses to approach up to 80–90% in asset utilization. The higher production rates and reduced reliance on direct labor that FMSs enable allow businesses to make labor savings that could reach 30–50%.

The new age in industrial automation

In many ways, we are only seeing the beginning of Industrial 4.0 and the implications it will have for businesses, the manufacturing industry, and society at large. What is assured is that this new era of industrial automation will enable an unprecedented amount of speed and accuracy of production.

At the same time, the manufacturing industry is being reshaped, making way for operations that are more connected and have a greater degree of precision and safety.

The key industrial automation trends to look out for will be:

- Industrial Internet of Things

- Shift from automated to autonomous operations

- Lower cost of robotic arms

- Increased adoption of collaborative robots

- Advances in machine vision

- Increased reliance on 3D printing

- Continued adoption of flexible production systems