Laser cutting and engraving are one of the most commonly-used processes in the industrial and manufacturing industries, and are found across numerous applications.

Therefore, for anyone involved in these industries or their adjacent businesses, it is important to know the major differences between the two types.

This blog compares the key differences between laser cutting vs. laser engraving, helping you to determine which is more useful depending on the industry you’re involved in.

Table of Contents

The business potential of the laser machine market

Laser cutting

Laser engraving

Key differences between laser cutting and laser engraving

Conclusion

The business potential of the laser machine market

To understand the importance of the laser cutting and engraving markets, it is useful to look at the profitability of both. For example, the global laser cutting machine market is expected to grow at a CAGR of 5.8% between 2022 and 2032 and reach a valuation of around US $5.97 billion by 2032.

On the other hand, the global laser engraving machine market size is expected to grow at a CAGR of 8.30% between 2023 and 2028, thus reaching a valuation of US $4.82 billion by 2027.

These projections are mainly based on the demand of these machines across major industries, such as the automotive, aerospace, electronics, electrical, packaging, architecture, interior design, signage, and advertising markets, among others.

Moreover, growing automation within these technologies has contributed to even more demand for these machines.

Now, let’s look at what defines a laser cutting versus engraving.

Laser cutting

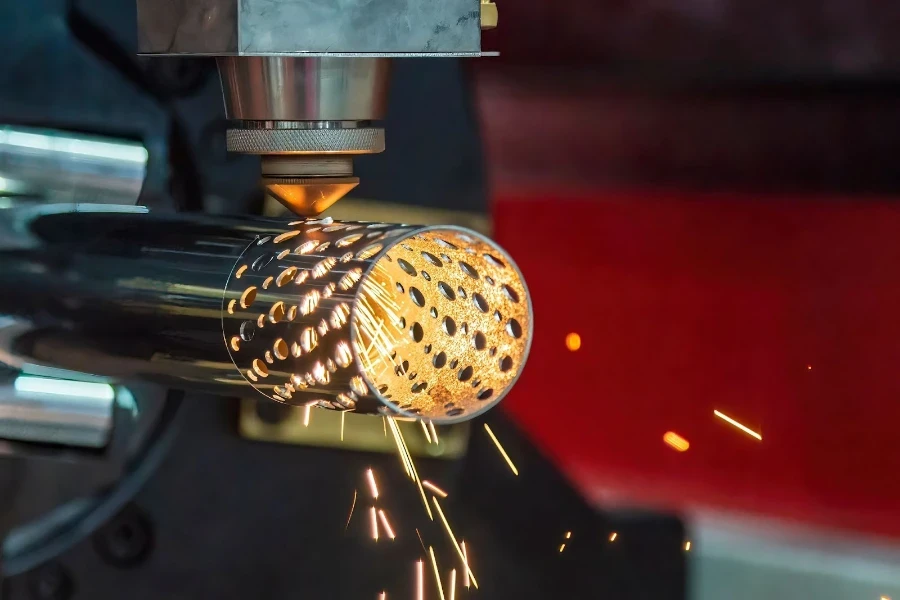

Laser cutting utilizes high-powered laser technology to cut through different materials of various thicknesses with force and precision. It basically uses intense heat to melt or vaporize materials, making it an entirely non-contact process.

Laser cutting is used in many industries due to its high versatility and high-accuracy cutting, creating minimal waste.

Laser engraving

Laser engraving also utilizes high-powered lasers, but unlike laser cutting, is mainly used to engrave patterns, texts, and intricate designs onto materials. Instead of cutting through the entire material, like in laser cutting, engraving only removes thin layers in order to make permanent engravings.

Laser engraving used in various industries, such as arts and crafts, jewelry, branding, fashion, and sign making, among others, due to the ease in which it can personalize materials through precision engraving.

Key differences between laser cutting and laser engraving

When it comes to the key differences between laser cutting and laser engraving, there are many.

Below are just a few of the differences based on several important factors that many industries look at when talking about the two techniques’ applicational uses.

Laser power

The first important factor when comparing these two processes is their laser power. Since laser cutters are often needed to cut through various materials, they usually require higher laser power (typically above 60W) compared to laser engravers (below 60W).

Cutting thickness

Laser cutters can cut through thicker materials, such as metals, wood, and acrylic, more efficiently. On the other hand, laser engravers are ideal for thinner materials and typically remove thin layers of a maximum depth of 0.25mm from materials.

Cutting speed

When it comes to cutting speed, a high-powered beam typically cuts through materials at a faster rate when compared to a low-powered one. It is ideal to use laser cutters at a high power with high cutting speed for improved efficiency and accuracy.

On the other hand, laser engravers are utilized at lower cutting speeds and power to ensure that intricate designs are engraved without error.

Operational accuracy

While both types of machine can offer high-accuracy cuts, the task at hand will define which is right for the job. For example, laser cutters require high accuracy when making clean, precise cuts. However, laser engravers are better at engraving fine details with neat finishes.

Size of materials

When it comes to the size of the materials needed to be cut, laser cutters are ideal for larger materials and bigger surface areas. On the other hand, laser engravers are more suited for managing smaller materials and work areas.

Design profile

Laser cutters and engravers are similar to CNC machines in that they require digital input to perform automated cutting and engraving tasks. Therefore, it is essential to understand the two types of design profile – raster and vector – related to these machines. Raster design is a bitmap image made of thousands of pixels, whereas vector design is made up of geometrical lines and curves based on equations. Laser cutters generally make use of the former, whereas laser engravers generally utilize both raster and vector design.

Additional parameters

When it comes to the parameters involved in laser cutting and engraving processes, laser cutters utilize parameters such as power, speed, frequency, and focus depth for optimization. On the other hand, laser engraves utilize parameters such as power, speed, and resolution for detailed engravings.

Auxiliary gases

Laser cutters generally use auxiliary gases, such as oxygen or nitrogen, in their cutting process. This helps in cutting efficiency when it comes to removing layers of materials. Meanwhile, laser engravers don’t need or make use of auxiliary gases as the process only involves the material’s surface.

Cost

The cost of these machines will be determined by the user’s requirements. Since laser cutters generally require higher power and more cutting features, they generally cost more compared to laser engravers, which tend to be more affordable and have lower operational costs.

Conclusion

Despite their distinct features, laser cutting and laser engraving are both important processes in a number of crossover industries.

To find laser machines that offer both laser cutting and laser engraving capabilities, as well as wholesale sellers with machines tailored to your target audience, make sure to check Alibaba.com.