Plastic granulators are machines used to recycle plastic waste. They do this by cutting down plastics into flakes or regrinds that are later used to make different products. They’re seen as important in preventing environmental pollution because they reduce the amount of plastic in the environment. This guide highlights what businesses need to know about plastic granulators.

Table of Contents

Plastic granulators: market share and demand

Essential Tips to consider when purchasing a plastic granulator

Types of plastic granulators

Target market for plastic granulators

Plastic granulators: Market share and demand

Plastic granulators are used to enable scrap plastic to be reused in the production of plastic. The market share of plastic granulators is $3.4 billion. Current trends in the plastic granulators market include incorporating some additives to help soften or harden the plastic, depending on where it’ll be reused, and mixing the granules with virgin material for the overall resin to maintain a certain quality.

Essential tips to consider when purchasing a plastic granulator

Acquiring a plastic granulator is subject to a few tips that every business owner should consider.

Rotor

There are four types of rotors depending on what’s being processed. Open, closed/solid, staggered, and segmented. The open rotor is suitable for heat-sensitive resins.

The closed rotor has no space between the knife and the shaft. Consequently, it allows cutting through thick feedstocks. The staggered rotor is suitable for cutting through heavy material, while the segmented rotor cuts through heavy material and increases the number of cuts per revolution.

Knife design

The knives are mounted on the stationary bed or directly in the rotor. The spacing between the knives will determine the type of granule. A small knife space will result in softer material, while a bigger space between the knives results in more rigid granules.

Maintenance

Proper maintenance is essential for the machine to produce high-quality granules for a long period. Maintenance will also reduce dust on the granules. As granulators are not designed with maintenance in mind, professional maintenance is something that businesses should take into consideration before purchasing.

Intended use

Businesses ought to know the use they will make of the plastic granulator. Some plastic granulators have a capacity of 1000 kg/hr, while others can process 3000 kg/hr. The method of granulation is also essential. Machines can use either extrusion, blow molding, injection molding, or recycling. The product being processed is another consideration, whether it’s bottles or sheets.

Types of plastic granulators

There are several types of plastic granulators as listed below.

Besides-the-press plastic granulator

Besides-the-press granulators can integrate into any molding or extrusion operation for resin collection.

Features:

- It comes with sound insulation.

- It has water-cooled cutting chambers.

- It features viewing screens for observing grinding as it takes place.

Pros:

- It can be configured for manual or automatic use.

- It’s especially suitable for shorter production runs.

Cons:

- It’s costly to acquire and maintain.

Thermoforming granulators

Thermoforming granulators are designed for inline and offline processing of flat materials.

Features:

- It has a die and edge through which material is moved and processed.

- Flattened material is then metered through the rollers before going to the granulator.

Pros:

- It provides relatively high-quality granules.

Cons:

- It can only process flat materials.

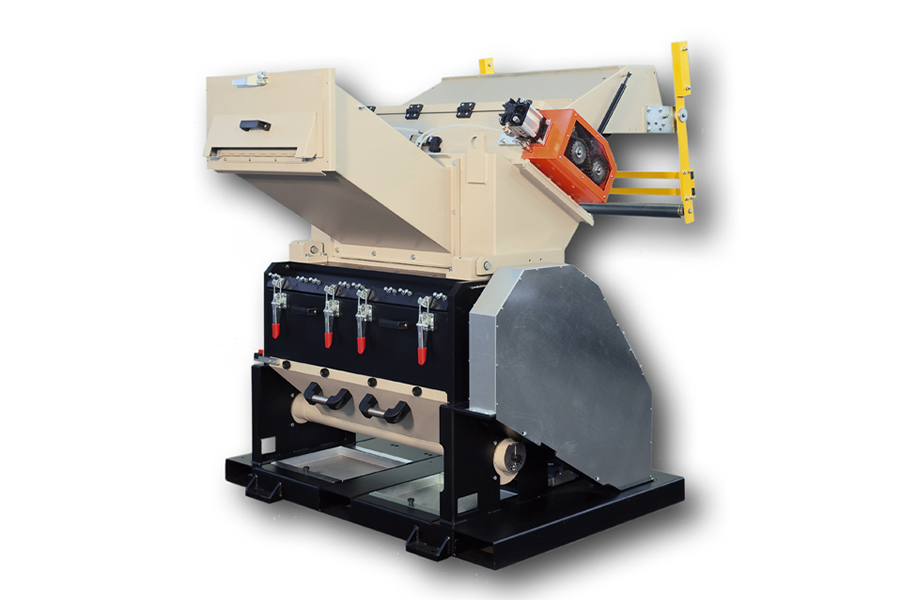

Combination granulators

Combination granulators have a shredder and a granulator in one machine.

Features:

- Heavier, denser material is first processed in the shredder before being taken to the granulator.

- The shredder provides consistent material size and volume to the granulator.

Pros:

- It provides high-quality granules due to preprocessing.

- It has a high level of throughput.

- A magnet can be attached to it to separate ferrous material from plastic.

Cons:

- It’s more mechanically complex to operate.

Central granulators

Central granulators work according to the double slanted scissor cut principle.

Features:

- It offers tangential or offset geometries for cutting materials.

- The cutting chamber can be programmed to cut higher-density parts.

Pros:

- It’s flexible to process large and small-volume parts.

- It’s effective for applications ranging from parts appliances to large injection and furniture appliances.

- The tangential offset provides the capacity to process many types of scrap with lower power.

Cons:

- It can quickly get clogged when loaded wrongly.

- It’s costly to acquire.

Target market for plastic granulators

Plastic granulators are expected to grow at a CAGR of 5.6% in 2027 to $ 5.1 billion. This growth is attributed to several factors, including increased industrialization across the globe and reduced production costs due to the use of granules. The Asia Pacific region is expected to dominate the market, followed by the North American region.

Conclusion

In this age where environmental pollution is rampant, plastic granulators are very important in recycling plastics. The article highlights the essential factors to take into consideration and the types of plastic granulators available. Therefore, it’s helpful for businesses that want to venture into the recycling of plastic waste.