Wood lathe machines are instrumental in turning wooden workpieces while cutting away unnecessary material. However, they need to be well maintained for wood lathe machines to operate effectively. Maintenance will guarantee smooth operation and long life, but it will also be cost-saving. This guide will cover why maintenance of wood lathes is essential and how it can be done professionally.

Table of Contents

Why is wood lathe maintenance important?

Structure of a lathe machine

How to maintain a wood lathe machine

Final thoughts

Why is wood lathe maintenance important?

There are several reasons why maintaining a wood lathe is essential as listed below.

- To remove the accumulation of debris and shavings.

- To minimize repairs.

- To ensure the machine is in top-notch condition.

- To lengthen the life of the machine.

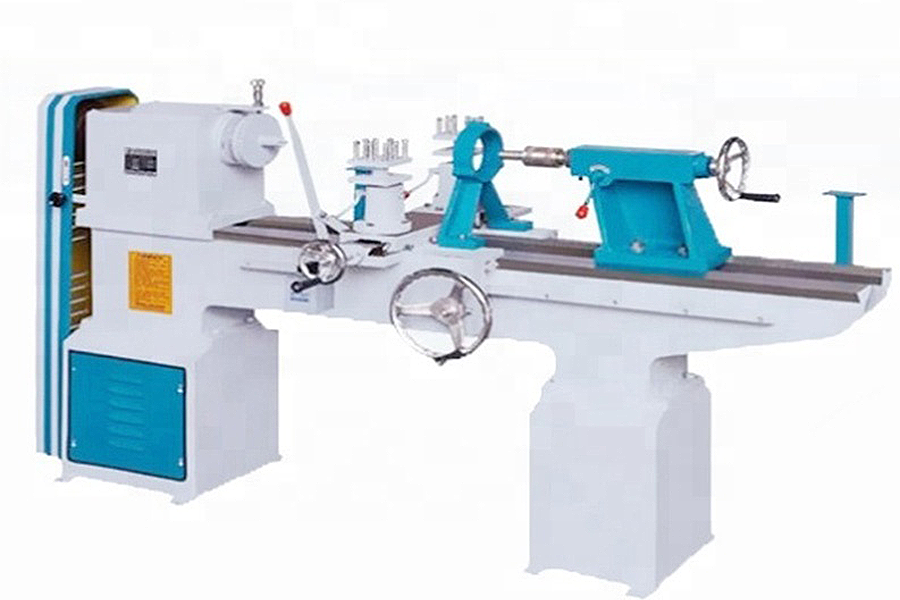

Structure of a wood lathe machine

The bed: It consists of the headstock, the tailstock, and carriage rails. It forms the mainframe of the lathe, and most parts of the lathe are attached to it.

The headstock: The headstock consists of the spindle, gears, the gear speed lever, and feed controls. It’s located on the left side of the lathe machine.

The tailstock: The tailstock is used to support the wood on the lathe. It’s located on the right side of the lathe machine.

The carriage: It’s located between the headstock and the tailstock. It contains the saddle, apron, saddle, compound rest, cross slide, and tool post.

Feed rod: It moves the rod right to left and vice versa.

Chip pan: It collects the chips produced during the lathe operation.

Handwheel: It moves various components such as the cross slide, tailstock, and carriage.

Lead screw: It moves the carriage automatically during threading.

How to maintain a wood lathe machine

Clean dust and debris

Dust is arguably the biggest enemy of wood lathe machines. It can easily cause damage to the machine if not taken care of. Wood shavings and dust can be removed from the lathe machine after turning wood. As for cleaning dust, the operator can use a vacuum cleaner or compressor to reach the hidden places in the lathe every week. Key areas to consider include blowing dust around the tailstock, electric motor, banjo, and the morse taper holes of the headstock and tailstock. A lint-free cloth can then be used to wipe out the blown areas.

Remove rust

Every metallic machine is susceptible to rust, and wood lathes are no exception. If anything, they stand a higher chance of getting rust when the machine turns greenwood. Greenwood has sap that contains tannins and compounds that accelerate rusting depending on the tree species. Parts made of cast iron such as tool rest, banjo, bed rails, and tailstock can quickly be coated with rust if they’re neglected. Despite these, some solutions can get rid of rust on wood lathes. Operators can use rust removal when rust has been spotted on the machine. Spraying the solution on rust will cause it to clear. Besides this, the sandpaper of 400 grit or lower can be used to sand the affected areas with remarkable results. It’s recommended that an inspection of rust is conducted every month.

Lubricate rails

The banjo needs to be able to move around effortlessly, and failure to do this indicates that it needs lubrication. Besides improving mobility, lubrication can preserve the metal because most oils give metals a coating that protects the surface from water, which causes rusting. Before applying lubrication, the bed rails and banjo should be cleaned well and dried before paste wax or any other lubricant is applied. The lubricant should be allowed to dry before the metal surface is buffed up with some clean, soft cloth. Ideally, lubrication should be applied weekly.

Inspect tool rest

The tool rest is bound to have marks on its top edge due to materials falling. During woodturning, catches can lead to woodturning tools smacking the bowl gouge or scraper on the tool rest. When the tool rest surface is interrupted, it’ll affect all the tools working on that surface. Therefore, a flat metal file can be used to make long angled strokes across the top of the tool rest to file away rough areas and smoothen the edge every 6 months.

Banjo and tailstock

Every month, the banjo and tailstock must be explicitly maintained because they’re attached to other components such as drive screws. Removing them from the lathe machine also allows the operator to clean off any debris or cavities that may have built up in the process of woodturning. The bottom surfaces that contact the bed rails can also be lubricated with a lubricant such as paste wax. It would also be possible to lubricate the drive screw because the tailstock has been removed. Once the banjo and tailstock are reinstalled, they should be able to move smoothly on the bedrails, and the locking screw should lock and unlock easily.

Check threads

Using the lathe machine, the threads on the headstock may become crossed, nicked, or damaged. Crossed threads are not smooth and fluid when attaching a faceplate or chuck as they result in friction. Cleaning with a toothbrush can clear up any clogs on the threads. Besides this, threading again may be another solution. Threads should be checked every month.

Check belt

The lathe belt connects the headstock to the motor. Due to the frequent rotations that it experiences, it must be inspected and cleaned weekly. The operator should check for any frayed edges, signs of damage, buildup of debris, or material under or on the belt. In case of frayed edges or damage, the belt should be replaced immediately.

Final thoughts

There is no doubt that the maintenance of wood lathes is important. However, unless businesses know how to conduct professional maintenance, they may incur unnecessary costs hiring technicians for work they can do themselves. This guide highlighted seven areas that should be focused on when maintaining a wood lathe machine. For a list of the best wood lathe machines in the market, visit Alibaba.com.